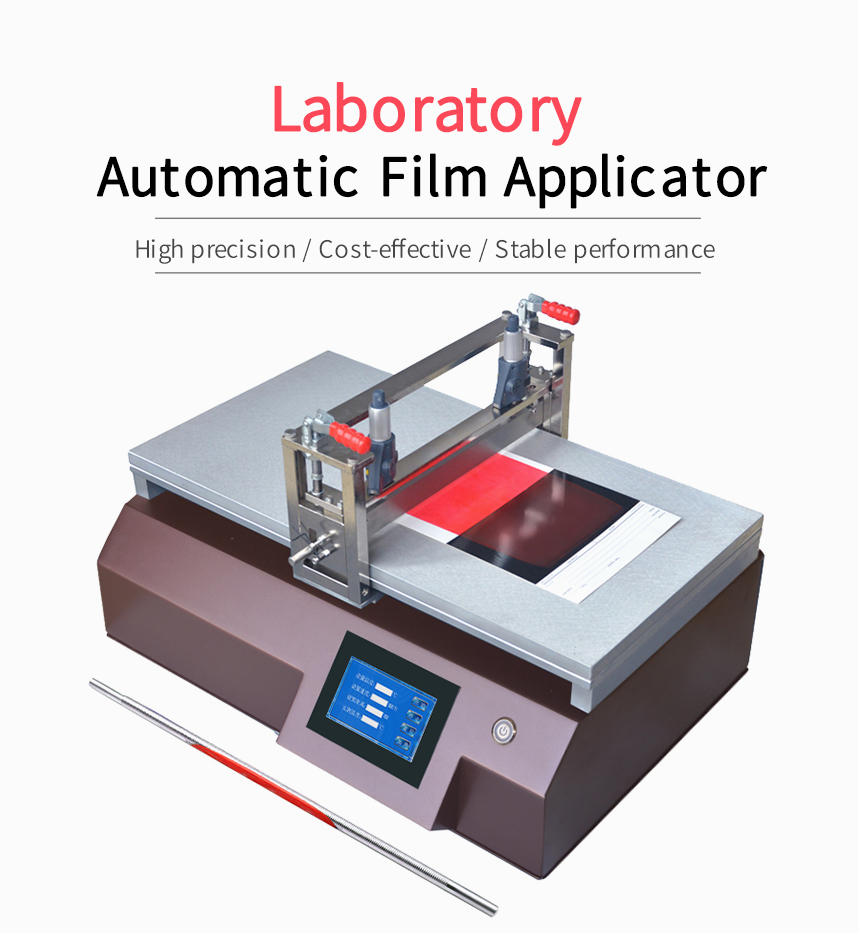

TBJ-X3-DJ2 Flat Coater slot die Coater 4-in-1 Multifunctional Film Applicator

SE

-

HUINUO TM3300pro High-precision Automatic Film Applicator with Drawdown Blade and Rod Applicator, Plus Heated Vacuum Table$ 5710.00SE

HUINUO TM3300pro High-precision Automatic Film Applicator with Drawdown Blade and Rod Applicator, Plus Heated Vacuum Table$ 5710.00SE -

China NBC-X4-DJ7 Floor Type Automatic Film Applicator Effective film area 700 * 1300mm$ 21216.00SE

China NBC-X4-DJ7 Floor Type Automatic Film Applicator Effective film area 700 * 1300mm$ 21216.00SE -

CHINA Removable metering rod & drawdown blade heating vacuum adsorption laboratory Film Applicator TBJ-X3-DJ11C$ 4457.00SE

CHINA Removable metering rod & drawdown blade heating vacuum adsorption laboratory Film Applicator TBJ-X3-DJ11C$ 4457.00SE -

China Intelligent Program Control Film Applicator TBJ-X3-DJ19 bar + Drawdown blade + Heating + Vacuum chuck type$ 7276.00SE

China Intelligent Program Control Film Applicator TBJ-X3-DJ19 bar + Drawdown blade + Heating + Vacuum chuck type$ 7276.00SE -

CHINA TBJ-X3-DJ31 Multifunctional Automatic Film Applicator Automatic Feeding, with Double Barrel 300 * 400mm$ 21999.00

CHINA TBJ-X3-DJ31 Multifunctional Automatic Film Applicator Automatic Feeding, with Double Barrel 300 * 400mm$ 21999.00

zy TBJ-X3-DJ2 Automatic Film ApplicatorSPEC

zy TBJ-X3-DJ2 Automatic Film ApplicatorDetails

zy TBJ-X3-DJ2 Automatic Film ApplicatorPacking list

- SKU

- NB038903

- Coating method

- Bar + adjustable drawdown blade + slot die

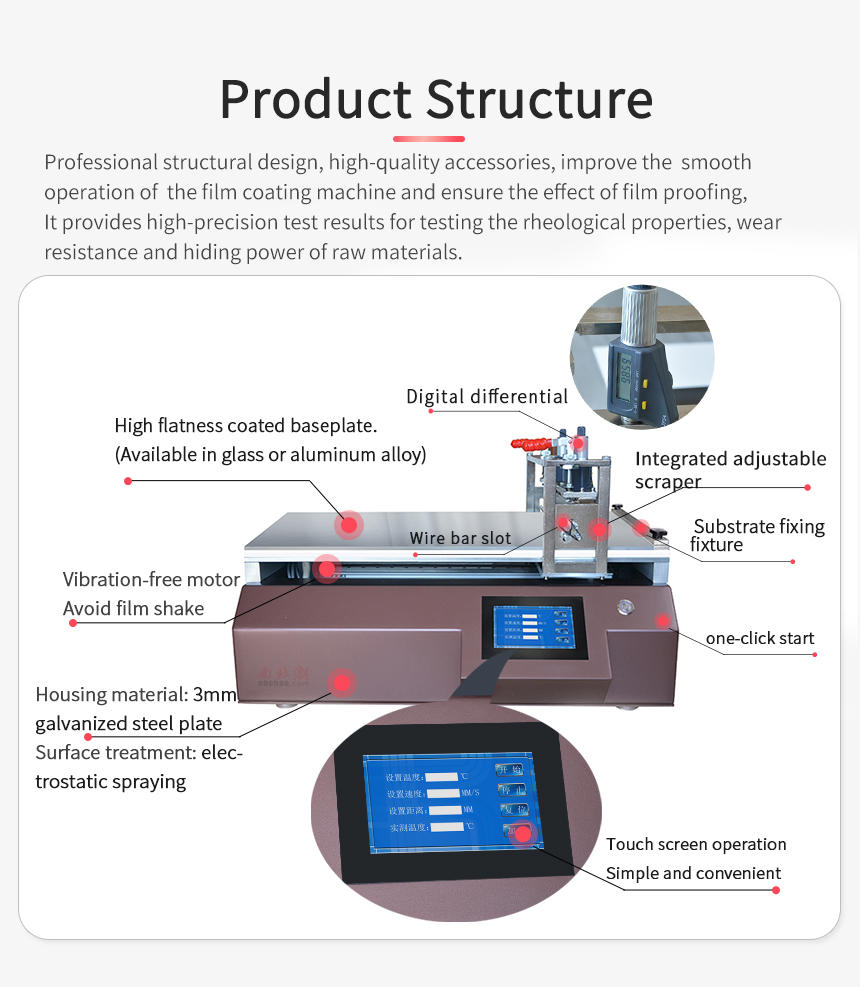

- Drawdown blade type

- Integrated drawdown blade

- Drawdown blade Accuracy

- ±0.003mm

- Drawdown blade thickness range

- 0~10Mm drawdown blade can be lifted

- Drawdown blade material

- 304 stainless steel

- Mayer Rod Thickness Range

- 1-571.5 μm (Spreader thickness according to bar model)

- Mayer Rod Accuracy

- ±0.001mm

- Coating speed

- 5-200Mm/s (< 5mm/s can be customized)

- Spreader distance control

- Numbers can be set arbitrarily within the range of 1-300mm

- Vacuum Area

- 250*400mm

- vacuum aperture

- Φ1.2mm

- Vacuum hole spacing

- 20*20mm

- Substrate clamping method

- Vacuum adsorption

- Control mode

- Touch screen control

- Host Power Supply

- 220V 50HZ

- Dimension

- 630*410*520mm

- Net Weight

- 65KG

- speed control

- Infinitely variable speed

- Bottom plate material

- aluminum alloy

- Heating Temperature range

- RT+~180℃

- Heating mode

- Baseplate heating

- Power

- 1500W

- Vacuum pump size

- 380*180*280mm

- Feeding Capacity

- Stainless steel syringe (Max: 100ml)

- Feeding speed

- 0.05-20 mm/s (barrel piston speed)

- Feeding drum Volume

- 1L

- Optional Accessories

- Leakage tank, substrate fixture, trimming horizontal height support foot device, Glass plate, silicone pad and Weight (for applications with uneven thickness of Spreader substrate), application width control baffle

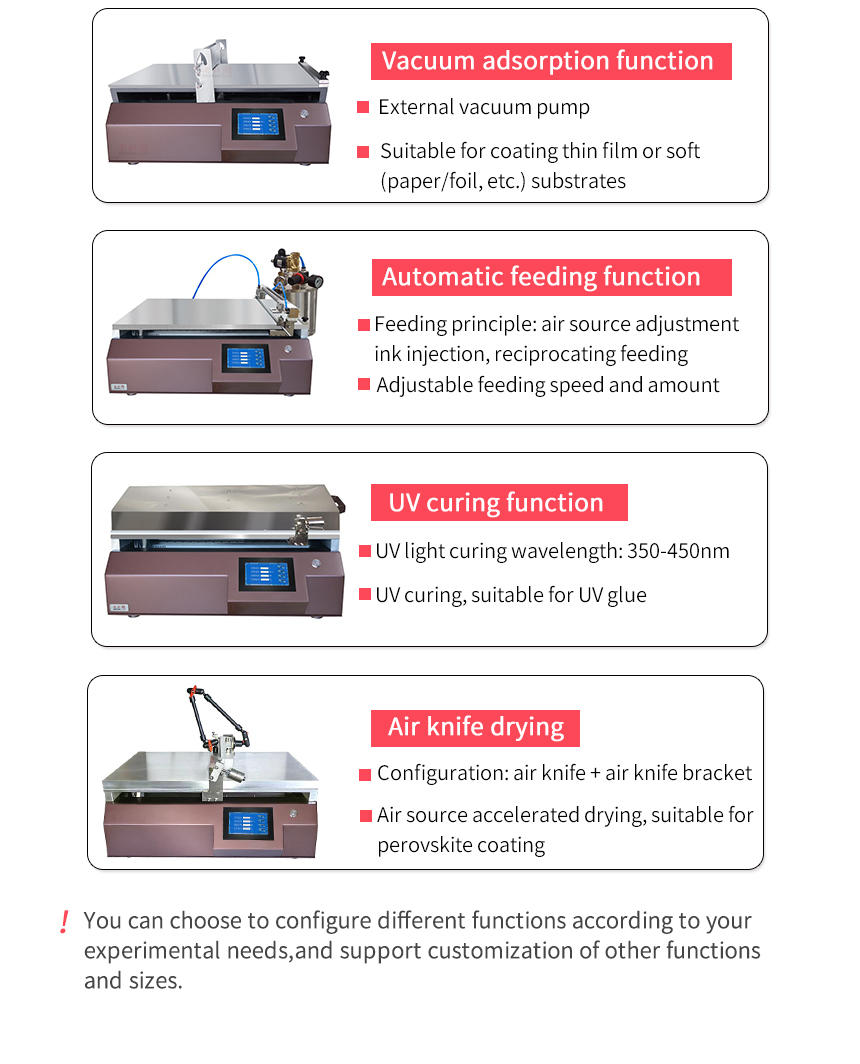

- customizable function

- Automatic lame plating device, UV curing device, air knife drying, remote control, upper infrared heating, double extrusion Spreader

product description

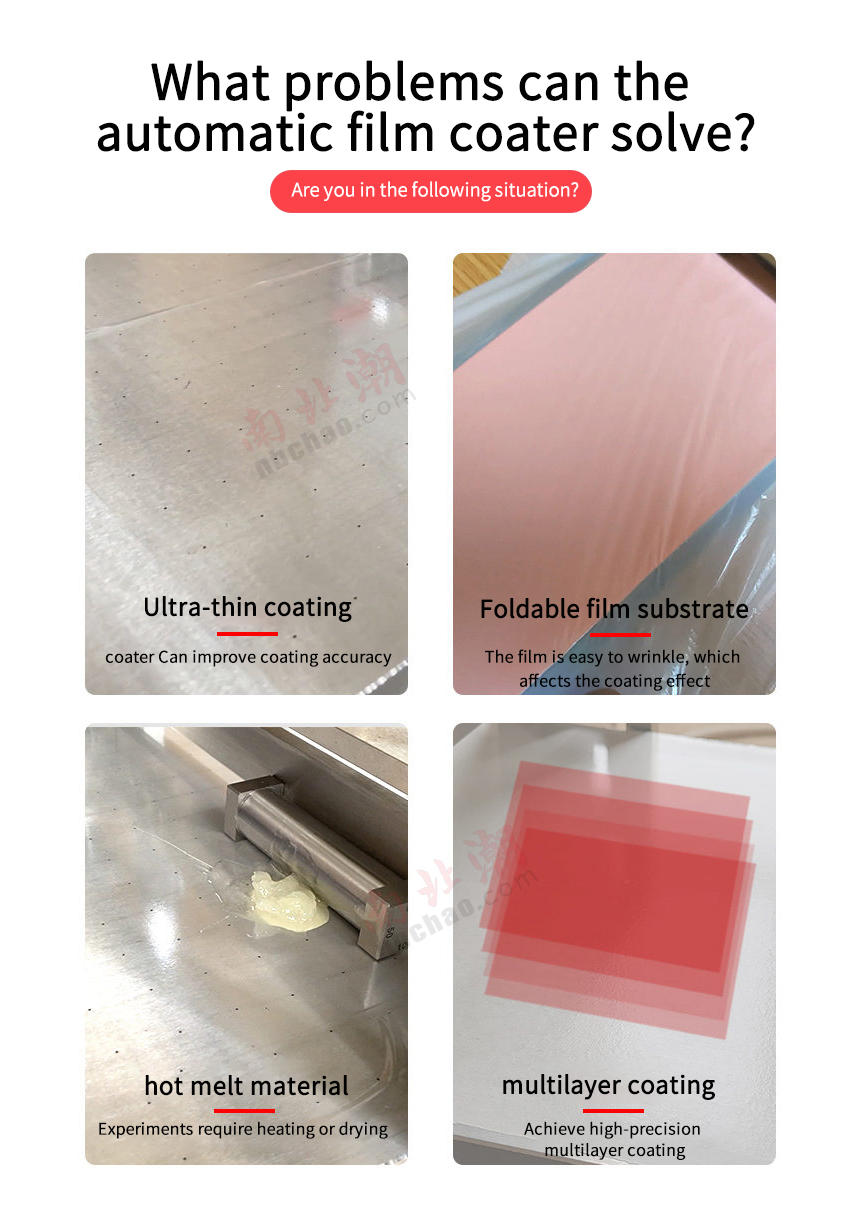

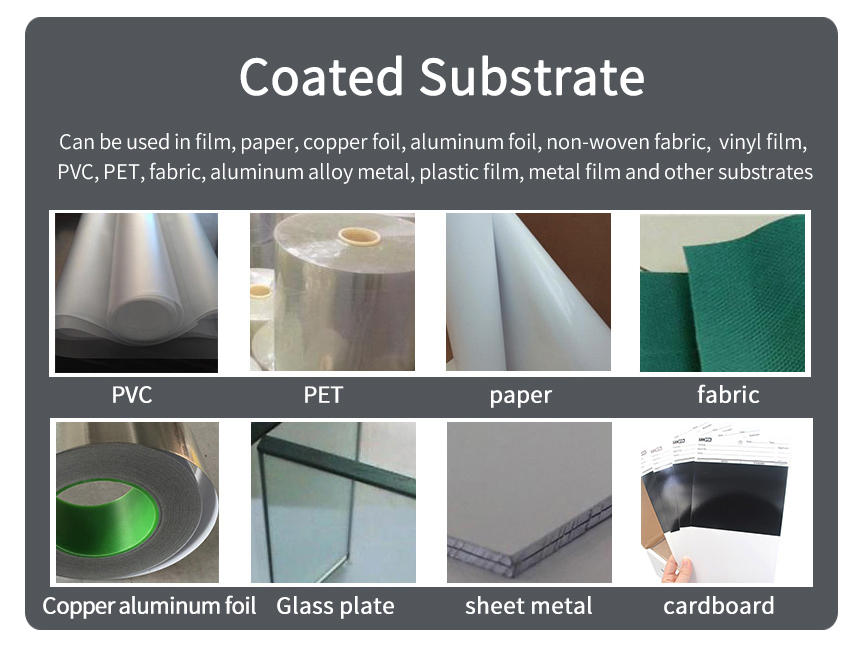

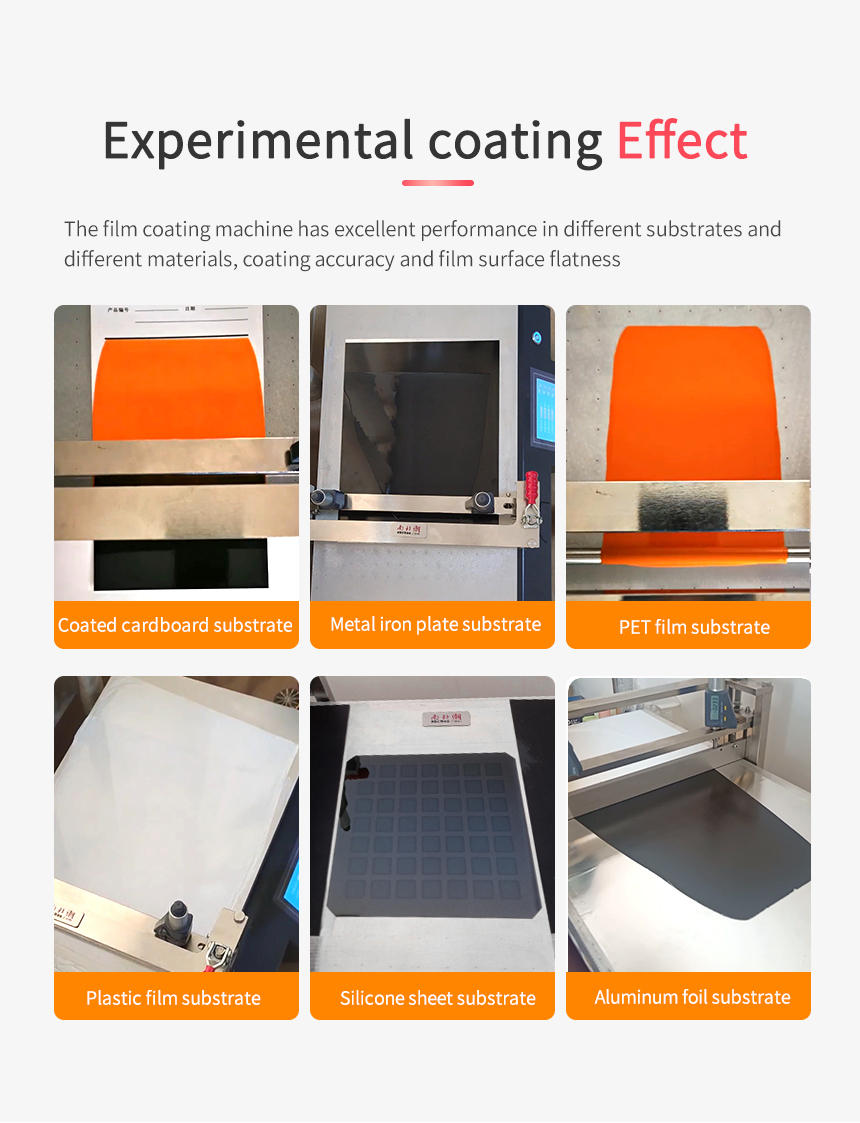

Extrusion flat-bed coating machine, composed of coating platform, automatic feeding system and control system, adopts slit extrusion feeding method for coating, including adjustable thickness scraper, wire rod and other coating processes, optional four sides preparer. It is mainly used in laboratory research and development, can work in a glove box, and also supports customization of production-type coating machines. The equipment is suitable for experiments on lithium batteries, glue, silicone oil, UV, ink, polymer materials, photoresist, cataplasm, hot melt adhesive, gel, plaster crystals, ceramics, slurry, medicine and other industries coating film. It can be coated on substrates such as film, paper, copper foil, aluminum foil, non-woven fabric, vinyl film, PVC, PET, cloth, aluminum alloy metal, plastic film, and metal film.

Optional

- 1Application of Vacuum adsorption Spreader Technique in Preparative Fluorescence Film on Release Membrane

- 2Selection and Technical Analysis of Laboratory Film Applicators in Liquid Crystal Dimming Film

- 3Experimental film coating machine case | Scrape coating slurry on release film

- 4Selection and Application of Laboratory Film Applicator in Wooden ground floor film laminating

- 5Analysis and application of self-adhesive laboratory coater technology

- 6Overview of film coater technology and process requirements

- 7Application and Optimization of PDMS Solution Coated on Glass by Small Film Applicator

- 8Fiberglass hot-melt adhesive coater technical analysis and operation guide

- 9Laboratory Technology and Application of Polyvinyl Alcohol Film Coating on Ultrafiltration Membrane

- 10Preparation of lithium battery slurry on aluminum foil and copper foil [Case of experimental coating machine]

TBJ-X3-DJ2

TBJ-X3-DJ2