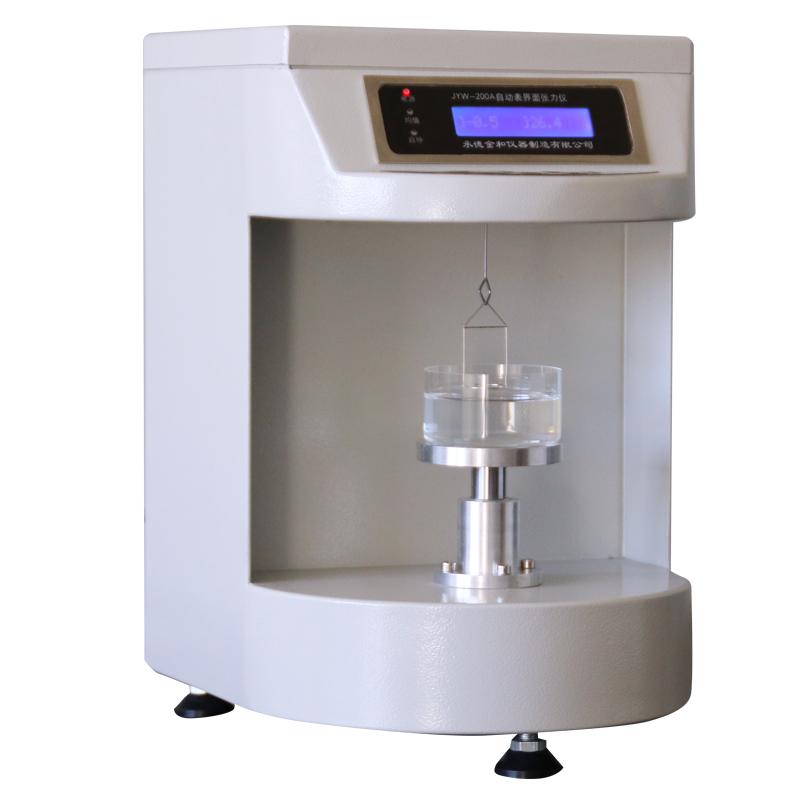

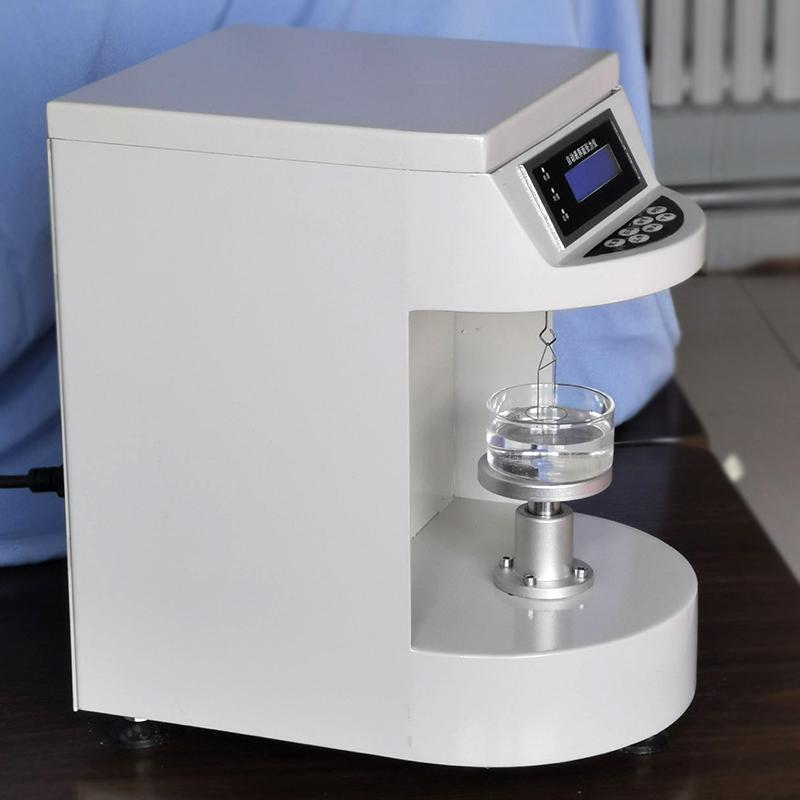

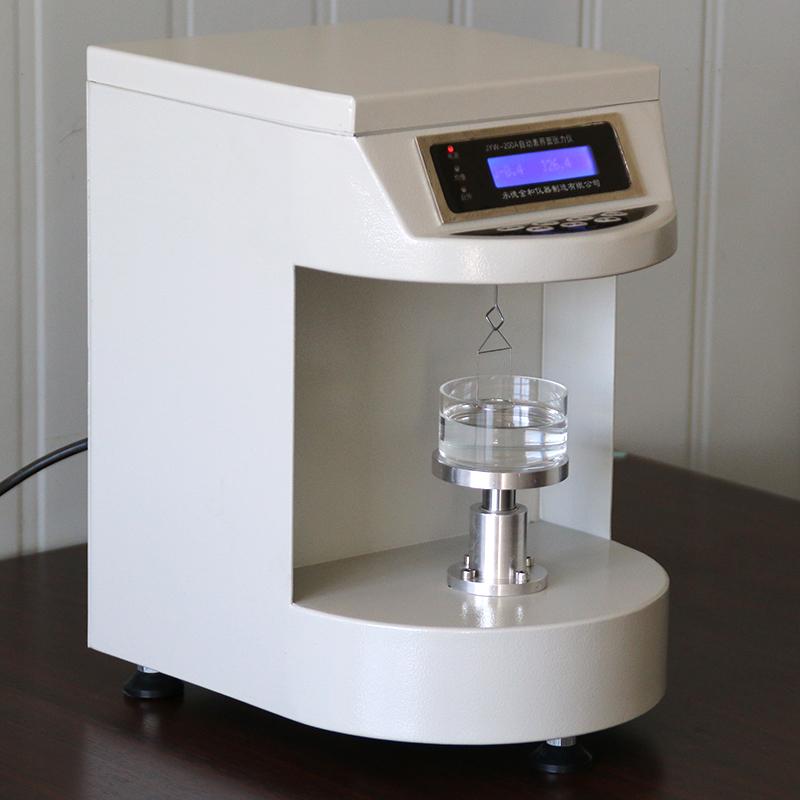

JINHE JYW-200B micro-control automatic watch/interfacial tension instrument, double calibrated automatic, computer operation

SEHuiNuo JYW-200B Automatic interfacial tensIon MeterSPEC

HuiNuo JYW-200B Automatic interfacial tensIon MeterDetails

HuiNuo JYW-200B Automatic interfacial tensIon MeterPacking list

- SKU

- NB038963

- Measurement range of surface tension

- 0~200mN/m

- resolution

- 0.01mN/m

- Indication Accuracy

- ≤ ±1%FS.

- Repeatability Error

- ≤ ±1%FS.

- Sample stage itinerary

- >35mm

- Sample stage traverse speed

- About 15mm/min

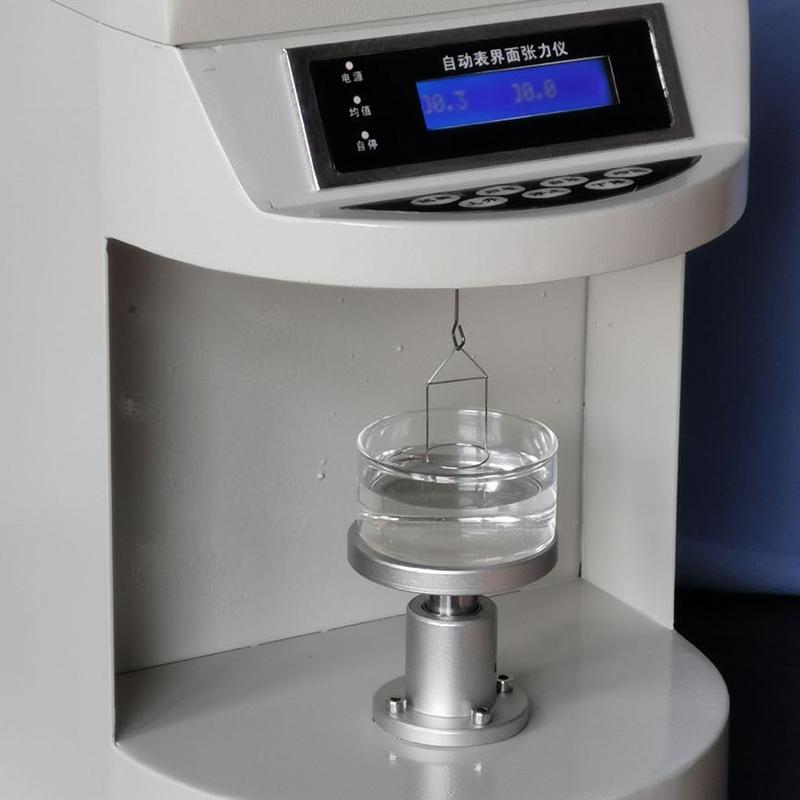

- Platinum Ring Specifications

- Platinum ring R9.55mm, platinum wire r0.3mm

- Machine Weight

- 7.5Kg

- Power supply Voltage

- 220V/50Hz

- Dimension

- 300*300*400mm

This machine is controlled by a microcomputer, and the newly developed data acquisition software collects data from the lower computer. The lower part of the machine has a unique structure, stable and durable, beautiful appearance, high degree of automation, accurate test results and strong repeatability.

Unique dual-calibration function: standard weight calibration meets the customer's requirements for issuing test certificates based on relevant standards, standard medium calibration meets the requirements of accurate test results and good repeatability, and the calibration method is simple and fast. The unique one-button test function makes customer testing more simple, convenient and accurate.

Features

1. The ring method test method adopts the scientific tension value correction method, that is, standard weight calibration and quasi-substance calibration.

①In order to eliminate the errors caused by factors such as the shape and pollution of the platinum ring in the ring method test, the gravity method is no longer used for correction, but two standard substances are used for correction. When the platinum ring is used for a long time, its shape changes, or When it is polluted and a test error occurs, it can be restored to normal as long as it is corrected with a standard substance, without having to replace the expensive platinum ring.

②Standard weight calibration method, which is the calibration method of the standard specification related to interfacial tension. According to this calibration method, the equipment is verified and a test certificate is issued.

2. The integrated shell is adopted, and the argon arc welding process is used. The entire support structure is not fastened by screws to ensure the stability of the support structure. (exclusive to this skin and instrument)

3. The internal screw structure is driven by a low-noise, low-speed DC motor, and the lifting shaft is precisely matched with oil-free self-lubricating bearings. The vibration is minimal and there is no shaking during the test. Reliability and durability are greatly improved, while ensuring test accuracy.

4. It is controlled by 32-bit ARM high-end single-chip microcomputer, with fast operation speed and high operation accuracy, and a specially compiled filter algorithm is used to ensure the stability and accuracy of the displayed value.

5. Adopt the high-end 24-bit AD converter of the American ADI company, with fast conversion speed and more accurate force value acquisition.

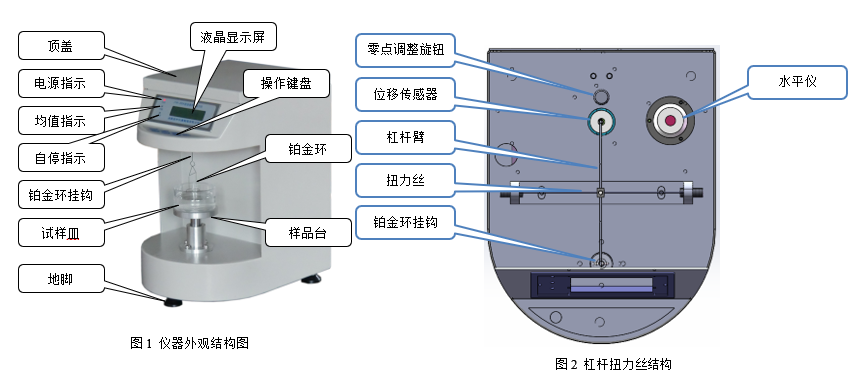

6. The improved torque wire lever structure makes the movement track of the sensor magnetic core as close to a straight line as possible to ensure the linearity of the test.

7. The domestic (CN) high-end LVDT displacement sensor is adopted, with good linearity, sensitive output signal and accurate impedance matching, which ensures the repeatability of the test

8. The instrument has an automatic stop function, which can be set to automatically stop when testing the surface tension. After the test is completed, the lifting table will automatically stop moving and display the tension value.

9. The unique automatic averaging function can automatically average and display the results of multiple tests, reducing the workload and intensity of the operator.

10. The lower computer has a digital LCD and keyboard, which can be directly operated through the lower computer, and the operating status is directly reflected on the computer, realizing two-way control between the computer and the lower computer. Without the computer, the lower computer can also work independently.

Software Features

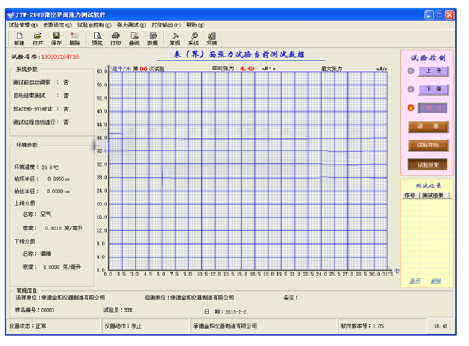

The test software has the functions of automatically drawing test curves, automatic zero adjustment, automatic ASTM D-971 formula correction, saving test results, generating test reports, etc.

1. It can display the real-time force value change curve, which is used to analyze the change of the interface or surface properties of the liquid in the process of being stretched by the platinum ring. The curve is saved as a picture, and can be printed together with the test report, or copied and printed independently.

2. The automatic ASTM D-971 formula correction can be set, and the actual tension value will be displayed immediately after the test is completed, without manual conversion.

3. Automatically record and display the average result when each sample is tested multiple times.

4. Multiple test data and graphs of each sample are saved as a whole.

5. Generate and print the test report function. Test reports can optionally include graphs and no graphs.

design standards

SY-T5370 "Determination Method of Surface and Interfacial Tension"

GBT 18396-2001 "Natural Latex Ring Method for Determination of Surface Tension"

GBT6541-86 "Determination of oil-water interfacial tension of petroleum products (ring method)"

QB-T 1323-91 " Determination of Surface Tension of Detergents by Ring Pulling Liquid Film Method"

- 1JJF 1464-2014《Calibration Specification for Interface Tensiometers》

- 2NY/T 1860.31-2016《Guidelines on the determination of physico-chemical properties of pesticides.Part 31: Surface tension of aqueous solutions》

- 3GB/T 11985-1989《Surface active agents--Determination of interfacial tension--Drop volume method》

- 4GB/T 38722-2020《Surface active agents—Determination of interfacial tension—Drawing up liquid films》

- 5GB/T 8077-2023《Methods for testing uniformity of concrete admixtures》

- 6GB/T 18396-2008《Natural latex - Determination of surface tension by the ring method》

- 7GB/T 42415-2023《Surface active agents—Determination of static interfacial tension》

- 8GB/T 18396-2001《Natural latex - Determination of surface tension by the ring method》

- 9GB/T 6541-1986《Petroleum products--Mineral oils--Determination of interfacial tension of oil against water--Ring method》

- 10JB/T 9388-2015《Interface tensiometers-Technical specification》

JYW-200B

JYW-200B