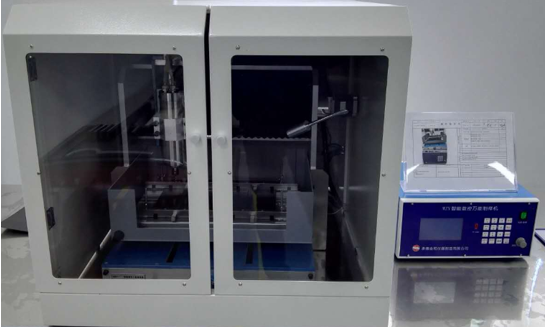

JINHE WZY-4030 numerical control multifunctional prototyping machine

SEJinHe WZY-4030 Number control prototypeSPEC

JinHe WZY-4030 Number control prototypeDetails

JinHe WZY-4030 Number control prototypePacking list

- SKU

- NB038970

- Maximum milling length

- 400mm (without dust cover), 300mm (with dust cover)

- Maximum milling width

- 300mm

- Maximum Film thickness

- 20mm

- Height space

- 100mm

- Spindle motor speed

- 24000r/min

- Control mode

- Manual control, program control

- provider

- Dumbbell sample preparation procedures, Impact spline production procedures, thermal deformation Vicat sample preparation procedures, notch sample preparation procedures covering all common materials

- Water chilling down system

- Yes.

WZY-4030 CNC multi-functional prototyping machine adopts new CNC technology, controls the three-axis linkage system through the program controller, drives the XYZ axis motor and supplements the high-speed spindle motor to form a high-precision milling machine system, and realizes the spline of non-metallic plates Cutting, dumbbell milling, impact notch milling functions.

This machine has incomparable characteristics of the traditional multi-functional sample making machine. Firstly, the shape of the sample it makes is not limited by the machine. As long as the program is provided, it can make samples of various shapes, such as bar shape, dumbbell shape, round shape, various shapes, etc. Regular graphics, etc., unlike the traditional multi-functional sample making machine, which can only make bar-shaped and dumbbell-shaped samples, and can only make dumbbell-shaped samples corresponding to the template. Secondly, its precision is very high. Whether it is cutting splines or milling dumbbells, the maximum machining error is only 0.05mm. Once again, it is basically not restricted by the shape of the sample, as long as it can be clamped on the platform, it can be processed. For example, a dumbbell-shaped sample can be cut directly from a large plate, a spline can be cut from any position of the plate, and different Splines that meet the size requirements are milled, etc.

When using this machine, if you cut simple rectangular non-standard splines, you can use manual cutting; if you cut dumbbell-shaped splines or other standard splines, our company provides common standard spline processing programs, which can be opened directly from the controller Processing; for users who need to process special shape samples, our company can provide programming services.

This machine can expand more processing functions besides processing samples

software function

The dumbbell-shaped sample preparation program covers all common materials, and the corresponding sample preparation can be completed by selecting the corresponding program.

Rectangular spline sample production function, suitable for making impact splines, thermal deformation splines, Vicat sample blocks and other specifications of rectangular samples.

The notch sample preparation function can stack multiple samples on the platform and complete the processing at the same time. The processing of notches with different specifications can be realized by changing the cutting tool.

Plate cutting function, to cut larger plates.

Pipe cutting function.

The functions of plane milling and vertical milling are used to process special-shaped materials and some materials removed from the entire machine into flat plates, and then process them into required samples.

machine configuration

One digital control prototype host.

Milling cutter for cutting. (including milling dumbbells) (cutting plates, pipes)

Face milling cutter.

Face milling cutter.

Notch milling cutter.

WZY-4030

WZY-4030