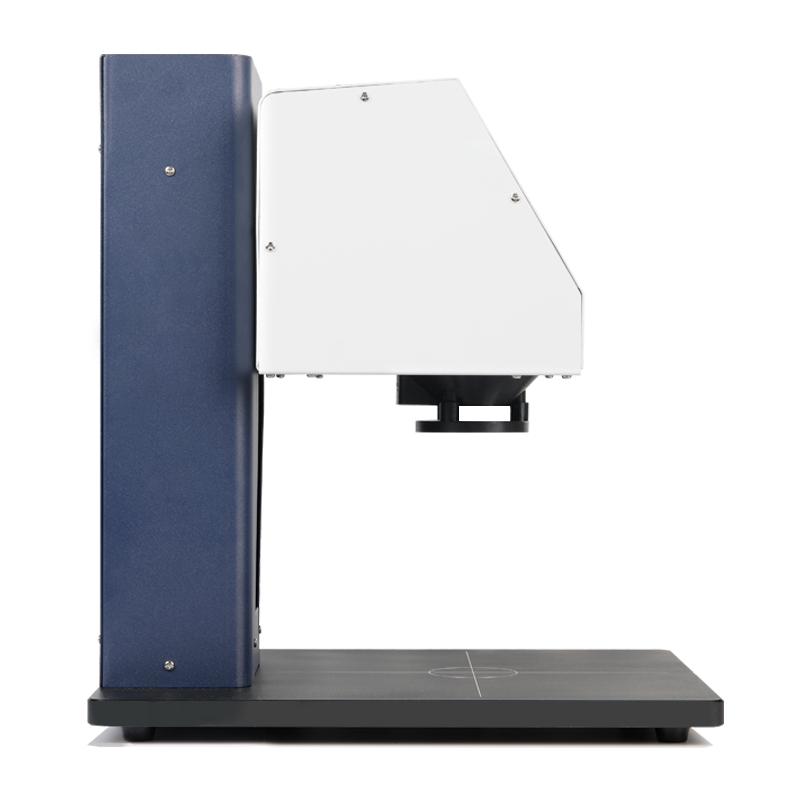

3NH YL4660 D/8 Contactless Desktop Colorimeter

SE-

3NH YL4668 D/8 Non-contact desktop Colorimeter automated production line

3NH YL4668 D/8 Non-contact desktop Colorimeter automated production line -

3NH YL4560 45 °/0 ° Non-Contact Colorimeter Measurable Phosphor

3NH YL4560 45 °/0 ° Non-Contact Colorimeter Measurable Phosphor -

3NH YL4520 45 °/0 ° Non-contact Colorimeter φ 20mm

3NH YL4520 45 °/0 ° Non-contact Colorimeter φ 20mm -

3NH YL4560 45 °/0 ° Non-contact Colorimeter Enhanced LED + UV Customizable caliber, automatic lifting

3NH YL4560 45 °/0 ° Non-contact Colorimeter Enhanced LED + UV Customizable caliber, automatic lifting -

3NH YL4520 45 °/0 ° Non-Contact Colorimeter Basic Edition

3NH YL4520 45 °/0 ° Non-Contact Colorimeter Basic Edition

3NH YL4660 Non-contact ColoriMeterSPEC

3NH YL4660 Non-contact ColoriMeterDetails

3NH YL4660 Non-contact ColoriMeterPacking list

- SKU

- NB039094

- Lighting method

- 45/0 (45 annular uniform illumination 0 ° reception); conforms to standard CIE No.15, GB/T 3978, GB 2893, GB/T 18833, ISO7724-1, ASTM E1164, DIN5033 Teil7

- lighting source

- Light spectrum LED light source

- Spectroscopic method

- Concave grating spectroscopy

- sensor

- 256-Pixel dual array CMOS image sensor

- Measurement Wavelength range

- 400~700Nm/10nm output

- Reflectance Measurement Range

- 0~200%

- Measurement caliber

- F20mm

- non-contact distance

- 7.5mm(±0.2mm)

- Sample height

- 0~160mm (using the original support baseplate)

- Distance adjustment method

- Manual adjustment, automatic adjustment (can store test height)

- Measurement mode

- Sample mode, quality control mode, continuous statistics mode

- Positioning method

- Camera positioning

- Color space

- CIE LAB,XYZ,Yxy,LCh,CIE LUV,HunterLAB

- Color difference formula

- ΔE*ab,ΔE*uv,ΔE*94,ΔE*cmc(2:1),ΔE*cmc(1:1),ΔE*00,ΔE(Hunter)

- Other chromaticity indicators

- WI (ASTM E313, CIE/ISO, AATCC, Hunter), YI (ASTM D1925, ASTM 313), Isochromatic Spectrum Index MI, lightfastmess, color fastness, force, coverage

- Viewing Angle

- 2°/10°

- Observation light source

- D65,A,C,D50,D55,D75,F1,F2(CWF),F3,F4,F5,F6,F7(DLF),F8,F9,F10(TPL5),F11(TL84),F12(TL83/U30)

- display mode

- Light spectrum map/data, sample chromatic value, color difference value/map, chromaticity map, Color simulation, pass/fail results, display tolerance can be set

- Measurement time

- Fast mode about 1.0s (adjustable from 0.2 to 1.5s)

- Store data

- 40,000 sample mode + quality control mode; 10,000 continuous statistics mode

- Sexual repeability

- Spectral reflectance: within 0.08% of standard deviation: chromatic value: ΔE * ab within 0.03 (after preheating, the average value of 30 whiteboard measurements at intervals of 5s)

- Inter-station difference

- ΔE * from < 0.2

- Measurement method

- Single measurement, average measurement (2~ 99 times)

- size

- 330*250*370mm

- Weight

- About 10Kg

- Power Supply

- DC 24V, 3A power adapter Power

- Lighting source life

- 5 years more than 3 million measurements

- Display

- TFT true color 7inch, capacitive touch screen

- Data Interface

- USB/RS-232, Bluetooth 5.0

- Operating language

- Simplified Chinese, Traditional Chinese, English

- Operating temperature range

- 0~40 ℃, 0~85% RH (no condensation), altitude: less than 2000m

- Storage temperature range

- -20~50 ℃, 0~85% RH (no condensation)

product description

YL4660 Spectrophotometer is a color measuring instrument that adopts D/8 (diffuse illumination, 8° direction reception, SCI includes specular reflection light) standard. The test probe and the sample to be tested are non-contact test, which can realize liquid and sauce , powder and other non-contact precision color measurement. Used for accurate color analysis and transmission in laboratories and R&D industries; it can also be used for accurate color measurement and color quality control in automated production lines; it is widely used in cosmetics, fruits and vegetables, food hygiene, plastic electronics, paint inks, printing, ceramics and other industries application. Its unique innovative design not only provides a non-contact measurement solution directly from the production line, but also ensures stable and high-precision measurement results.

The YL4660 non-contact Spectrophotometer will not touch the sample during the measurement process, preventing damage to the sample and avoiding cross-contamination.

Features

1. According to the actual height of the measured object, the measuring head can be moved up and down and the height of the test sample can be stored.

2. TFT true color 7inch capacitive touch screen; concave grating

3. 256-pixel dual-array CMOS image sensor

4. Test Wavelength range 400~700nm, 10nm output

5. The lighting source is full-spectrum LED light source and UV light source

6. A variety of measurement modes: quality control mode, sample mode, continuous statistical mode, etc. to meet more customer needs

7. Large-capacity storage space, sample mode + quality control mode 30,000 records, continuous statistical mode 10,000 records

8. Built-in camera positioning

9. The PC-side software has powerful extension functions

Instrument display map

Application

45/0 non-contact desktop Spectrophotometer , non-contact test between the test probe and the tested sample, to achieve non-contact precision color measurement of liquids, sauces, powders, etc. Used for color analysis and transmission in laboratories and R&D industries; it can also be used for color measurement and quality control in automated production lines; it is widely used in cosmetics, fruits and vegetables, food hygiene, plastic electronics, paint inks, printing, ceramics and other industries.

YL4660

YL4660