YIHENG BPG-9140A Forced Air Drying Oven Input Power 1550W

SE-

MODERNER GFX-9140A Forced Air Drying Oven 136L

MODERNER GFX-9140A Forced Air Drying Oven 136L -

MODERNER GFX-9145A Forced Air Drying Oven 136L

MODERNER GFX-9145A Forced Air Drying Oven 136L -

YIHENG BPG-9040A Precision Forced Air Drying Oven Input Power is 850W$ 583.00SE

YIHENG BPG-9040A Precision Forced Air Drying Oven Input Power is 850W$ 583.00SE -

YIHENG BPG-9070A Precision Forced Air Drying Oven Input Power 1100W$ 718.00SE

YIHENG BPG-9070A Precision Forced Air Drying Oven Input Power 1100W$ 718.00SE -

YIHENG BPG-9240A Desktop precision Forced Air Drying Oven Input Power is 2050W$ 1186.00SE

YIHENG BPG-9240A Desktop precision Forced Air Drying Oven Input Power is 2050W$ 1186.00SE

YiHeng BPG-9140A Drying ovenSPEC

YiHeng BPG-9140A Drying ovenDetails

YiHeng BPG-9140A Drying ovenPacking list

- SKU

- NB003917

- Power

- AC 220V 50Hz

- Input Power

- 1550W

- Temperature range

- RT+10~200℃/RT+10~250℃

- Temperature Resolution

- 0.1℃

- Temperature Fluctuation

- ±1℃

- Temperature Uniformity

- ±2.5%

- Shelf (std.)

- 3pcs

- Interior size

- 500*360*800mm

- Dimensions

- 645*640*1114mm

- Volume

- 150L

- Timer

- 1~5999min

- Net Weight

- 81kg

- Gross Weight

- 117Kg

- Packing size

- 760*760*1350mm

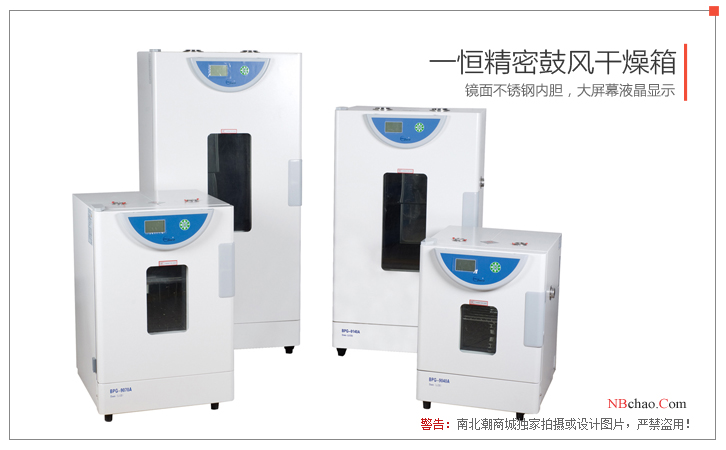

Introduction of BPG-9140A Forced Air Drying Oven

The temperature control range of Yiheng BPG-9140A Forced Air Drying Oven is 10~250℃, and it adopts liquid crystal display, which is convenient for observation and operation. The BPG-9140A Forced Air Drying Oven adopts a mirror stainless steel liner and is equipped with 3 shelves. BPG-9140A Forced Air Drying Oven has an input power of 1550W and a volume of 150L.

Features and advantages

1. Humanized design

● Large-screen LCD display, multiple sets of data displayed on one screen, menu-style operation interface, easy to understand, easy to observe and operate.

● BPG-9140A precision Forced Air Drying Oven adopts mirror stainless steel liner, the four corners are semi-circular transition, and the shelf bracket can be freely loaded and unloaded, which is convenient for the cleaning work of the studio.

● The left side of the cabinet is equipped with a test hole with a diameter of 25mm, which can be wired arbitrarily according to the needs of the place where it is placed.

2. Self-diagnosis function

● When the BPG-9140A precision Forced Air Drying Oven breaks down, the LCD will display the failure information, and the fault point can be seen at a glance.

3. Multi-segment programmable controller (optional)

● Microcomputer program controller, time and heating rate, can conduct heating and drying test at a very fast speed.

● It can preset 7 sections and 63 steps programmable, each section has 9 steps, and the setting time of each section is 1~99 hours and 59 minutes. The startup and shutdown time can be preset, and the speed of the circulating fan is adjustable.

● Multi-segment programmable control and menu-based operation interface can simplify the complex experimental process and truly realize automatic control and operation.

4. Convenient data processing (optional)

● BPG-9140A precision Forced Air Drying Oven can be connected to a printer, 485 communication interface or USB data transfer interface (U disk), and record the temperature with a computer and a printer.

The speed and time curve provide a strong guarantee for the storage and playback of experimental process data.

5. Safety function

● Independent temperature limit alarm system, and sound and light alarm to remind the operator to ensure safe operation without accidents. (optional)

● High or low temperature and over-temperature alarm.

Optional

1. Multi-segment programmable temperature controller

2. Embedded printer

3. Independent temperature limit controller

4. RS485 interface and communication software

5. Wireless alarm system (SMS alarm system)

Pictures

- 1SL 144.7-2008《Calibration method of Electric Forced Air Drying Oven》

- 2GB/T 9995-1997《Determination of moisture content and moisture regain of textile--Oven-drying method》

- 3GB/T 6102.1-2006《Test method for moisture regain in raw cotton by oven drying》

- 4GB/T 6978-2007《Test method for the determination of scoured yield of greasy wool - Drying oven method》

- 5GB/T 10514-2012《Determination of free water for nitrophosphate - Oven method》

- 6GB/T 24131.1-2018《Rubber, raw—Determination of volatile matter content—Part 1:Hot-mill method and oven method》

- 7GB/T 30648.5-2015《Paints and varnishes—Determination of resistance to liquids—Part 5: Temperature-gradient oven methods》

- 8SL/T 144.7-2008《Calibration method of Electric Forced Air Drying Oven》

- 9GB/T 32710.10-2016《Safety requirements for environmental testing and conditioning equipment—Part 10: Electric gravity convection ovens and forced ventilation ovens》

- 10GB/T 30435-2013《Electric gravity convection and forced ventilation ovens》

BPG-9140A

BPG-9140A