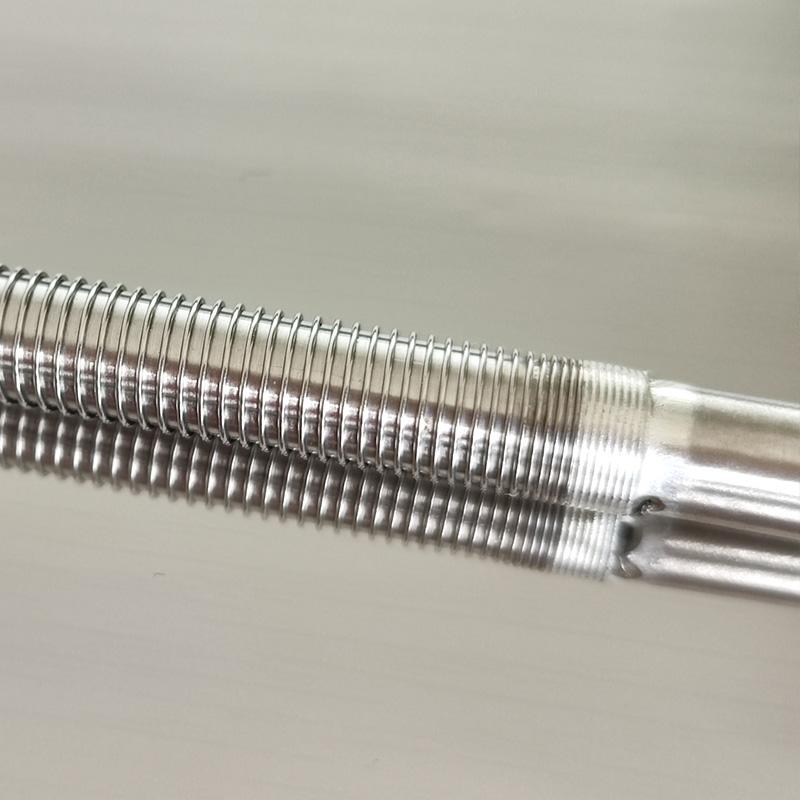

RDS 120G #3/8 "Gap Applicator rod prepative film thickness 274.3μm

SEProduction process gap wire-wound, wet film thickness 274.3μm, diameter 9.52mm, Total length 400mm, Spreader width 300mm, material stainless steel.

$172.00/piece

PromotionLoading...

Coupon

Model:

RDS 120G# 3/8" Applicator rod 3/8 "SPEC

RDS 120G# 3/8" Applicator rod 3/8 "Details

RDS 120G# 3/8" Applicator rod 3/8 "Packing list

- SKU

- NB039480

- Production process

- Interstitial wire-wound

- WFT

- 274.3µm

- diameter

- 9.52mm

- Total length

- 400mm

- Application width

- 300mm

- material

- stainless steel

120G# 3/8"

Applicator rod 3/8 "

Production process gap wire-wound, wet film thickness 274.3μm, diameter 9.52mm, Total length 400mm, Spreader width 300mm, material stainless steel.

Preparation principle

Following the Mayer Rod film coating principle, for higher viscosity fluids, the gap film coating rod reduces clogging and eliminates scratches. By winding smaller wires at pitches (see photo), the cavity created is wide and shallow, allowing thick coatings to flow better. Smaller wires create smaller interruptions in the coating flow, allowing for more complete wetting of the coating.

FAQ

QWhat is the difference between a gap Applicator rod and a wire-wound Applicator rod?

A

Applicator rods are mainly for high viscosity fluids. The standard wire-wound drawdown bar is suitable for wet-films below 1000cps, while the gap Applicator rod is suitable for fluids with high viscosity from 1000 to 3000cps

QCan this gap bar scrape high viscosity fluid samples?

A

Yes, unlike standard Myaer rods, gap rods are suitable for scraping fluids in the viscosity range of 1000 to 3000cps, but not beyond 3000cps. These numbers are not absolute, and Miscellaneous factors must also be considered.

QDoes this wire-wound gap open bar support customization?

A

Yes, the standard length is 40cm. If you need to customize Miscellaneous specifications, please contact customer service.

Knowledge

120G# 3/8"

120G# 3/8"