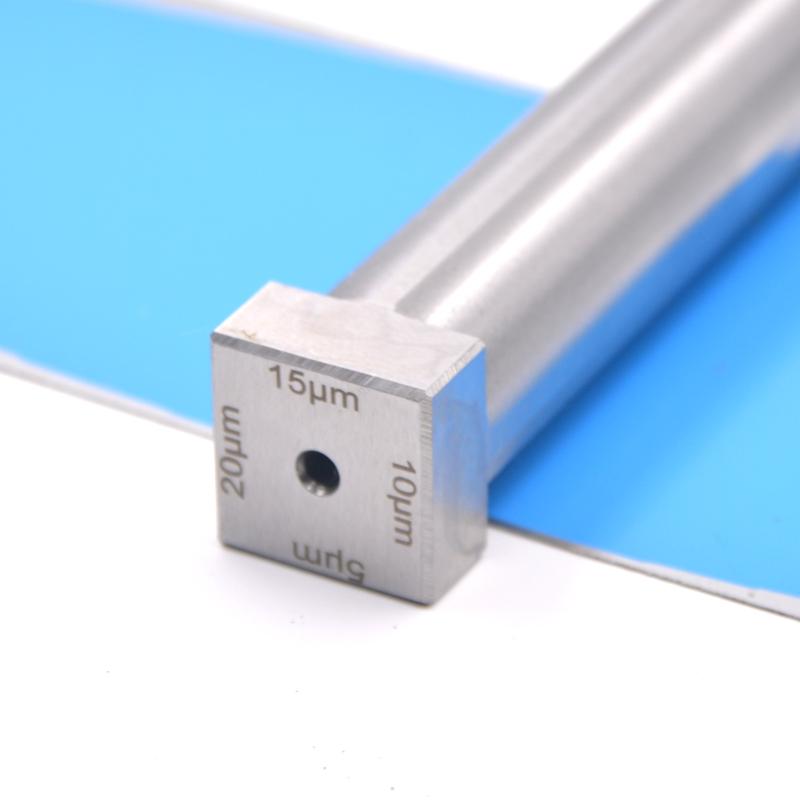

PUSHEN /Pushen ZBQ 160/5-20 um 4-sided Film Applicator Film width 160mm

SEPushen ZBQ 160/5-20um Extended Film ApplicatorSPEC

Pushen ZBQ 160/5-20um Extended Film ApplicatorDetails

Pushen ZBQ 160/5-20um Extended Film ApplicatorPacking list

- SKU

- NB039543

- type

- multi-faceted

- WFT

- 5/10/15/20μm

- application width

- 160mm

- material

- Hard stainless steel

- Net Weight

- 300g

Introduction

The Pushen four-sided manual applicator is made of hard stainless steel and is suitable for scraping a film of specified thickness and width on a flat and solid substrate. Each Film Applicator has 1 or 4 high-precision Fixed film thickness ensures accuracy, and a variety of film widths are available for customization.

ZBQ series parameters

| model | Coating thickness (μm) | Coating film width (mm) | Total length (mm) |

| ZBQ5/10/15/20 | 5,10,15,20 | 160 | 100 |

| ZBQ10/15/20/25 | 10,15,20,15 | ||

| ZBQ25/50/75/100 | 25,50,75,100 | ||

| ZBQ30/60/90/120 | 30,60,90,120 | ||

| ZBQ50/75/100/150 | 50,75,100,150 | ||

| ZBQ100/150/200/250 | 100,150,200,250 | ||

| ZBQ100/200/300/400 | 100,200,300,400 | ||

| ZBQ250/500/750/1000 | 250,500,750,1000 |

Advantages

●The material is high-grade stainless steel, which ensures that the applicator is not corroded by acidic or alkaline substances in paint or cleaning agent.

●Mainly used to coat a certain thickness of wet film to measure the color and hiding power of the sample or to prepare a sample, etc.

●Multi-face I-shaped wet film device can be applied to coat 4 different film thicknesses.

You only need to change the angle to get 4 different paint film thicknesses, and the operation is simple and convenient.

Introduction of paint leveling

The so-called leveling property of the coating refers to the smooth and smooth state of the coating film after the coating is applied.

If the surface has good leveling properties, there will be no irregularities such as orange peel, brush marks, ripples, and shrinkage cavities. Usually people directly observe with the naked eye to compare the sample with the standard sample in parallel to judge the quality of the leveling property of the coating film. This method varies from person to person and is highly subjective.

Application

Due to the convenience, simplicity and rapidity of the operation of the Fineness Meter, it plays an important role in the particle measurement of coatings, inks, dyes, powders and pigments.

It is used to measure the particle size and degree of dispersion of pigments and impurities in paints, pigments, color pastes, inks and other liquids or slurries, known as fineness detection, so as to control the quality of dispersed products in production, storage and application. Widely used in plastics, pigments, printing inks, paper, ceramics, medicine, food and other fields.

ZBQ 160/5-20um

ZBQ 160/5-20um