CHINA 50L programmable constant temperature and humidity testing machine constant temperature and humidity machine -40~150 ℃

-

CHINA NBC-50L-40 small constant temperature and humidity machine, high-low Temperature Test Chamber -40 ℃/50L$ 2499.00SE

CHINA NBC-50L-40 small constant temperature and humidity machine, high-low Temperature Test Chamber -40 ℃/50L$ 2499.00SE -

CHINA NBC-50L-60 Programmable Temperature Humidity Cyclic Chamber -60 ℃/50L$ 2698.00SE

CHINA NBC-50L-60 Programmable Temperature Humidity Cyclic Chamber -60 ℃/50L$ 2698.00SE -

CHINA NBC-50L-40 programmable Humidity Chamber paint panel -40 ℃/50L$ 2488.00SE

CHINA NBC-50L-40 programmable Humidity Chamber paint panel -40 ℃/50L$ 2488.00SE -

HZAOC hzaoc GDJS-50B Temperature Humidity Cyclic Chamber -30~150 ℃/50L$ 6148.00SE

HZAOC hzaoc GDJS-50B Temperature Humidity Cyclic Chamber -30~150 ℃/50L$ 6148.00SE -

HZAOC GDJS-50C high-low temperature Humidity Cyclic Chamber -40~150 ℃/50L$ 6305.00SE

HZAOC GDJS-50C high-low temperature Humidity Cyclic Chamber -40~150 ℃/50L$ 6305.00SE

AISRY Programmable Constant Temperature & Humidity Test ChamberSPEC

AISRY Programmable Constant Temperature & Humidity Test ChamberDetails

AISRY Programmable Constant Temperature & Humidity Test ChamberPacking list

- SKU

- NB039647

- Interior size

- 350*300*500mm

- Dimensions

- 870*850*1370m

- Temperature range

- -40~150℃

- Temperature control Accuracy

- ±0.1℃

- Temperature Fluctuation

- ±0.5-1℃

- Temperature Uniformity

- ±1.5-2℃

- Humidity control range

- 20~98%R.H

- Humidity Control Accuracy

- ±0.1℃

- Humidity stability

- ±1-2%R.H

- Humidity Uniformity

- ±1-3.0%R.H

- Heating rate

- 3 ℃/min nonlinear no-load

- Cooling rate

- 1 ℃/min (no-load nonlinear)

- Total Weight

- 130KG

- operating Voltage

- 220V/50HZ

- Permissible Voltage Variation

- ±10%

- Maximum Power

- 5kw

- Chamber material

- Mirror stainless steel plate (SUS #304)

- Enclosure Material

- Mirror stainless steel plate (SUS #304)

- top opening

- Laser cutting and opening according to the test sample drawings provided by the customer

- Insulation material

- German Bayer polyurethane rigid foam + high density fiberglass

- Shelf

- 1 layer (punching treatment of high-strength SUS304 #stainless steel plate)

- Maximum number of shelves

- 4 layers (shelf spacing is adjustable)

- Shelf Weight

- 20KG

- Test chamber door

- Single door, double-decked door, left opening

- test hole

- A 50mm diameter test hole is opened on the left, and the durability, parcel and protection of the wiring harness far exceed that of domestic ordinary materials

- Display

- Imported 7-inch color touch screen display (touch screen operation control)

- Temperature Resolution

- ±0.1℃

- Humidity resolution

- ±0.1%R.H

- Temperature Control system

- 9 groups of P.I.D control parameter setting, P.I.D automatic calculation

- Main components

- Air Switch: Japan, Push Button Switch: Taiwan, China, Phase Sequence Protector: Taiwan, China, Time Relay: Taiwan, China, Intermediate Relay: Japan, AC Contactor: Taiwan, China, Solid State Relay: Japan, Sensors: Taiwan, China

- Ambient Temperature

- 0~30℃

- Specification Environment

- 5~25℃

- Environmental requirements

- Miscellaneous items should not be placed within 60CM around the instrument, and the installation ground should not be severely tilted

use

This constant temperature and humidity environment Test Chamber can simulate various temperature and humidity environments. It is mainly used as equipment to test the performance of materials in various environments and to test the heat resistance, cold resistance, dryness resistance, and moisture resistance of various materials. Suitable for quality testing of electronics, electrical appliances, communications, instruments, vehicles, plastic products, metals, food, chemicals, building materials, medical, aerospace and other products.

Control method: Using the Balanced Temperature and Humidity Control System (BTHC), the induction system transmits the actual data in the Test Chamber to the controller. The controller controls the SSR, multi-stage intelligent output, and balances the output power of the temperature and humidity system to ensure that the temperature and humidity in the Test Chamber are The temperature and humidity are fully stable, and it has an energy-saving function, which reduces the power usage of the instrument to a greater extent and ensures long-term accurate and stable operation of the instrument.

Technical features

1. The product has beautiful appearance, reasonable structure, precise technology, simple and convenient operation and stable and reliable performance.

2. The controller adopts a large color LCD human-machine touch dialogue LCD human-machine interface controller, which is simple to operate, easy to learn, stable and reliable, and displays complete system operating conditions, execution and setting program curves in Chinese and English, and can realize RS232 Computer interface docking, remote control of the instrument directly through the computer.

3. The refrigeration cycle system uses a compressor: an original imported Japanese "Sanyo" brand fully enclosed compressor (optional French Taikang compressor). All components are imported from Japan, France, the United States, Italy and other producing areas. Refrigeration The agent uses American environmentally friendly refrigerant (R23A, R404A).

4. There is a reserved test hole with a diameter of 50mm on the left side of the test box.

5. It has a fully automatic, high-precision system loop, any machine movement, PLC locking processing, all using PID automatic calculation control, and the temperature in the entire area has high precision and high stability.

6. Specially designed air circulation system and sensing system, the air outlet and return air sensor are detected and controlled to ensure the temperature uniformity in the Test Chamber and avoid any dead spots.

7. Adopt an enlarged observation window and 4 layers of tempered glass to provide a wider field of view.

8. The instrument has a comprehensive protection system, including power overload protection, leakage protection, control loop overload, short circuit protection, compressor protection, grounding protection, over-temperature protection, alarm audible prompts, etc. When any abnormal situation occurs, the fault will be automatically displayed on the screen immediately. Point out the reason and automatically shut down.

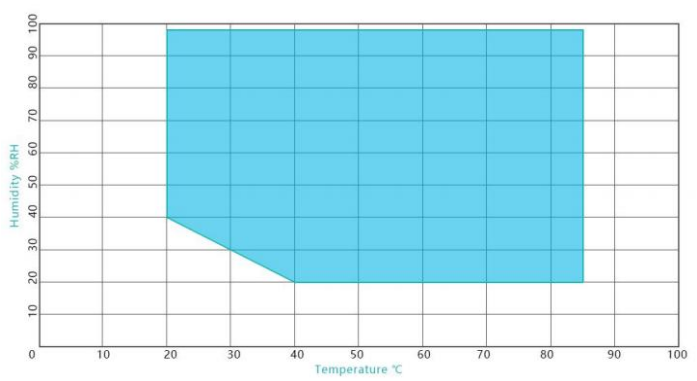

Temperature and humidity control range curve chart

Heating system

Multi-section heating tubes are used, combined with PID modules, to ensure temperature stability; segmented heating fully saves energy.

The heating tube is made of high temperature resistant and anti-corrosion alloy tube to extend its service life.

humidification system

The circular split humidifier avoids the freezing phenomenon that occurs with Water Tank humidifiers during low temperature testing.

The humidification tube is made of special alloy and can be dry-heated for more than 1 hour when the instrument fails and lacks water. With the high temperature alarm module, it effectively extends the service life of the humidification system. Built-in Water Tank and drawer-type water filling box are convenient and beautiful.

Equipped with water circulation system, saving 40% water.

It has a water quality filtration system to avoid clogging of the humidification system and reduce the frequency of cleaning.

Wind circulation system

1. High resistance wind circulation motor

2.Multi-wing fan blades

3. Specially designed fan forced air circulation system

Cooling System

Compressor: Original imported Japanese "Sanyo" brand fully enclosed compressor (optional French Taikang compressor)

Condenser: fin-type multi-section condenser with integral forced cooling fan

Evaporator: fin-type multi-stage automatic load capacity adjustment evaporator, combined with energy-saving regulating valve, to achieve forced refrigeration and constant temperature refrigeration segmented control

Refrigerant: The United States imports new environmentally friendly refrigerants R404A and R23A to achieve zero pollution to the environment.

Refrigeration Oil: American Ice Bear Refrigeration Oil

Filter dryer: Italian castor filter dryer

Solenoid valve: Japanese Lugong solenoid valve

Copper pipes: The pipes used in the refrigeration system are all made of imported copper material. Its advantages are good flexibility, not easy to break, and better shock-absorbing effect on the long-term vibration characteristics of the refrigeration system.

controller

Imported 7-inch color touch screen display

Touch screen direct button type (touch screen operation control)

Temperature and humidity simultaneously programmable controller

Chinese and English display

High contrast large LCD display controller with adjustable backlight function.

Accuracy: temperature ±0.1℃, humidity ±1%RH

Resolution: temperature ±0.1, humidity ±0.1%RH

With upper and lower limit standby and alarm functions

Temperature and humidity input signal selection PT 100ΩÃ2 (dry bulb and wet bulb)

9 sets of PID control parameter settings, PID automatic calculation

Dry and wet bulb automatic correction

Temperature and humidity set (SV) and actual (PV) values ââare directly displayed

Can display the currently executing program number, segment, remaining time and number of cycles

Operation accumulated time function

The temperature and humidity program setting values ââare displayed in a graphic curve, with the function of real-time display of program curve execution.

Equipped with a separate program editing screen, at least 5 segments of temperature, humidity and time can be input on each page

Chinese and English can be switched at will.

The fault prompt screen is displayed.

Screen backlight can be adjusted

The screen display protection function can be scheduled or turned off manually.

Usable program groups: Maximum 120 groups

Usable memory capacity: 1200 parts in total

Repeatable command execution: each command can be executed up to 999 times

The program is created in a conversational style, with functions such as editing, clearing, and inserting.

SEGMENTS time setting 0 ~ 99Hour59Min

It has power-off program memory and can automatically start and resume program execution after power is restored.

fulfill the standard

The performance indicators comply with the requirements of GB5170, 2, 3, 5, 6-95 "High Temperature, Constant Humidity, and Alternating Humidity Test Equipment for Basic Parameter Verification Methods of Environmental Tests"

Environmental Test Procedure Test B: High Temperature Test Method GB 2423.2-89 (IEC68-2-2)

Environmental Test Regulations Test Ca: Constant Humidity and Heat Test Method GB/T 2423.3-93 (IEC68-2-3)

Environmental test regulations test Da: alternating damp heat test method GB/T423.4-93 (IEC68-2-30)

- 1GB/T 11158-2008《Specifications for high temperature Test Chambers》

- 2GB/T 5170.2-2017《Inspection methods for environmental testing equipments—Part 2: Temperature testing equipments》

- 3GB/T 2423.4-2008《Environmental testing for electric and electronic products - Part 2: Test method - Test Db: Damp heat,cyclic ( 12h+12h cycle)》

- 4GB/T 2423.34-2005《Environmental testing - Part 2: Test methods - Test Z/AD: Composite temperature/humidity cyclic test》

- 5GB/T 2423.25-2008《Environmental testing - Part 2: Tests methods - Test Z/AM: Combined cold/low air pressure tests》

- 6GB/T 5170.8-2017《Inspection methods for environmental testing equipments—Part 8:Salt mist testing equipments》

- 7GB/T 2423.3-2016《Environmental testing—Part 2:Testing method—Test Cab:Damp heat,steady state》

- 8GB/T 5170.8-2017《Inspection methods for environmental testing equipments—Part 8: Salt mist testing equipments》

- 9GB/T 10589-2008《Specifications for low temperature Test Chambers》

- 10GB/T 2423.2-2008《Environmental testing - Part 2: Test methods - Tests B: Dry heat》