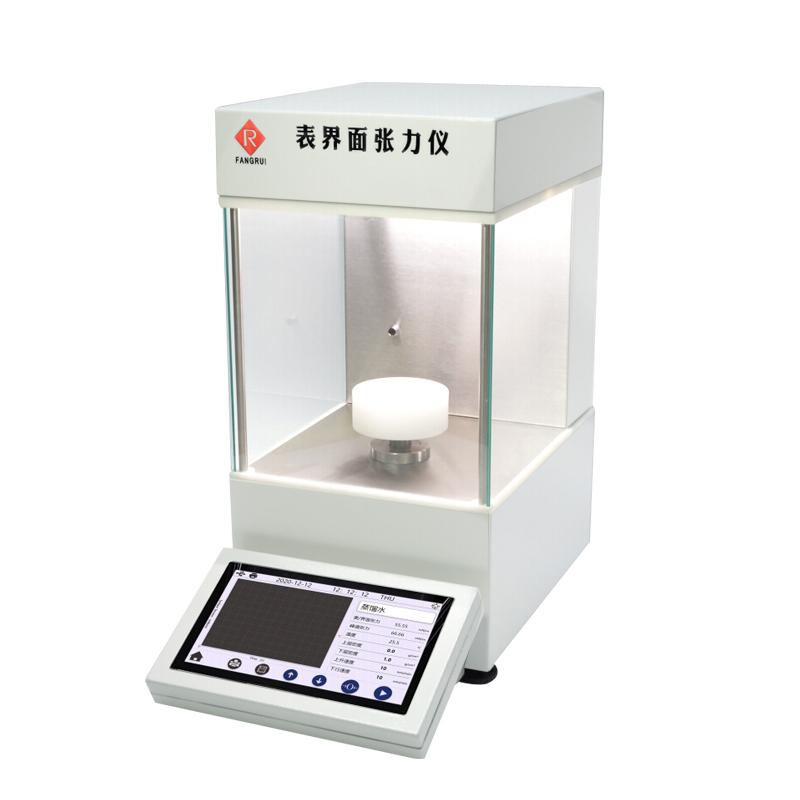

FANGRUI Q500 automatic Surface Tensiometer platinum plate method, range 500mN/m accuracy 0.1mN/m

SEFangRui Q500 platinum plate method Surface TensioMeterSPEC

FangRui Q500 platinum plate method Surface TensioMeterDetails

FangRui Q500 platinum plate method Surface TensioMeterPacking list

- SKU

- NB039700

- Measuring method

- Platinum plate method

- Measurement range of surface tension

- 0~500mN/m

- Surface tension Accuracy

- 0.001mN/m

- Operation mode

- Automatic lifting, automatic measurement

- Lifting speed

- 0~300mm/min can be adjusted arbitrarily

- Temperature Measurement Range

- -40 ℃~ 250 ℃ (PT100 Temperature Sensors are required)

- Display mode

- 7-Inch touchscreen, direct data reading

- data mode

- Data storage/view/print support

- Measurement time

- Regular within 60 seconds

- Interface

- RS232 (printer) or USB flash drive

- Data processing software

- Standard ST Flash software

- Dimension

- 47*24.5*47.5cm

- Horizontal adjustment method

- Electronic level adjustment

- Net Weight

- 18kg

- Power supply Voltage

- 110V or 220V, 50W

- Meet the standard

- ASTM D971、ASTM D1331、ASTM D1417、DIN EN 14210、DIN EN 14370、ISO 304、ISO 1409、ISO 6889

Features

1. The Q series tensiometer provides many expansion modules to expand the application range of the instrument, which is used to measure various characteristics of the surface and interface, which greatly improves the flexibility of its use. The main measurement principle is to accurately obtain the force between the measuring accessory or the sample to be measured when it is wetted by a liquid, the instrument uses standard methods including the DuNoüy ring method, the Wilhelmy plate method To measure the surface and interfacial tension of liquids. In addition, with the necessary optional accessories, the instrument can also be used to accurately measure the density of liquids.

2. The spacious sample room is equipped with a transparent glass sliding door, which can protect the room from disturbing air flow. A built-in electronic level helps to fine-tune the sample stage for precise force measurements.

3. The built-in measurement program can control the sample stage to ensure that there is no human interference in the measurement process. The running speed can be adjusted according to the experimental requirements and can be accurately repeated. The use of dynamic, smooth-running drives eliminates negatively affecting vibrations. In addition, the long-term drift of the force sensor is reduced to a minimum.

4. Through the 7-inch touch screen, simple and intuitive operation can be realized. Intuitive operation on the touch screen is a hallmark of the new generation of tensiometers, allowing easy control of the sample stage and other components both before and during a measurement.

5. The built-in measurement data management menu is convenient for viewing data and supports external printer operation. All measurement data files can be transferred through the U disk to be converted into Excel files, which is convenient for management, recording and arrangement of measurement data.

6. The machine program has a password management function to ensure that the data can be traced and prevent data modification and accidental deletion.

Application

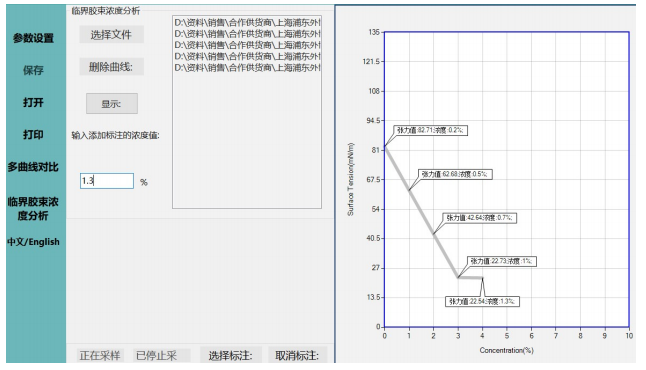

Evaluation of Surfactant Effectiveness and Efficiency by Measuring Critical Micelle Concentration

Wetting properties of tablets, active pharmaceutical ingredients and excipients

Wettability of paints and coatings

Oil aging degree detection

Coating wettability and adhesion

Cosmetic Development

Study on Wetting Properties of Ink

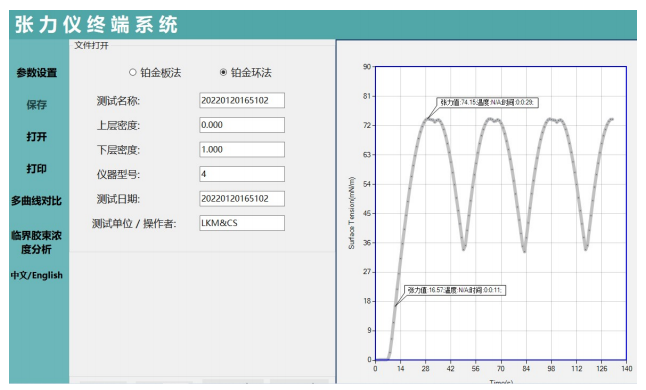

Transparent measurement and data management software ST Flash

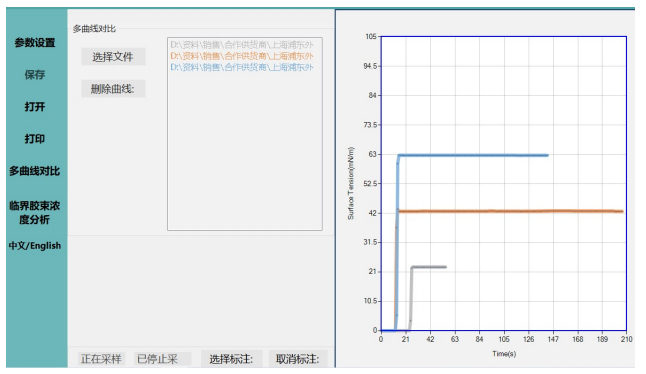

1) The simple operation of the Q series tensiometer is closely combined with the clear and clear user guidance of the software. Our ST Flash software supports easy results management through automatic summary diagrams, comprehensive measurement reports and transparent data organization functions, and also supports CMC analysis and calculation.

2) Support data collection, and can mark the data for easy viewing and comparison.

3) The collected data is saved in TXT file format, which is convenient for viewing and conversion, and the graphic file is generated in PDF format for printing.

4) Support simultaneous comparison of up to 8 sets of data.

5) ST Flash software provides a toolkit for analyzing CMC concentration.

6) The software supports Chinese and English operation and display.

Standards

ASTM D971 Standard Test Method for Interfacial Tension of Oil-Water by Ring Method

ASTM D1331 Standard Test Method for Surface and Interfacial Tension of Surfactant Solutions

ASTM D1417 Standard Method for Testing Synthetic Rubber Latex

DIN EN 14210 Surfactants - Determination of interfacial tension of surfactant solutions by the stirrup or suspension ring method

DIN EN 14370 Surfactants - Determination of surface tension

ISO 304 Surfactants - Determination of surface tension by the pulling film method

ISO 1409 Plastics/rubber — Polymer dispersions and rubber latexes (natural and synthetic) — Determination of surface tension by the ring method

ISO 6889 Surfactants - Determination of surface tension by the pulling film method

- 1Comparison of Fangrui's different series of automatic watch interfacial tensIon Meters

- 2Fangrui surface tensIon Meter test data deviation, how to solve?

- 3What are surface tension, contact angle, hydrophilic and hydrophobic surfaces?

- 4Measurement principle of interfacial tensIon Meter [video demonstration]

- 5What coating defects can be avoided by testing the surface tension properties of coatings?

- 6Analysis of the difference between contact angle meter and Surface Tensiometer

- 7Coating surface tension and its effects

- 8Types, applications and evaluation methods of levelling agents

- 9Selection guide for Surface Tensiometers

- 10Comparison of Liquid Surface/Interfacial Tension Testing Methods: Plate vs. Ring Method

- 1JJF 1464-2014《Calibration Specification for Interface Tensiometers》

- 2NY/T 1860.31-2016《Guidelines on the determination of physico-chemical properties of pesticides.Part 31: Surface tension of aqueous solutions》

- 3GB/T 11985-1989《Surface active agents--Determination of interfacial tension--Drop volume method》

- 4GB/T 38722-2020《Surface active agents—Determination of interfacial tension—Drawing up liquid films》

- 5JB/T 9388-2015《Interface tensiometers-Technical specification》

Q500 platinum plate method

Q500 platinum plate method