JINGKELIAN QGM-65 Three-roll Grinder with hard chrome plating

SEJingKeLian QGM-65 (roll chrome plating) Three-roll GrinderSPEC

JingKeLian QGM-65 (roll chrome plating) Three-roll GrinderDetails

JingKeLian QGM-65 (roll chrome plating) Three-roll GrinderPacking list

- SKU

- NB039764

- Motor power

- 0.55kW

- Overall Dimensions

- 450*450*430mm

- Weight

- 70kg

- Roller diameter

- 65mm

- speed ratio

- 1:3:9

- Medium roll speed

- 88rpm

- Material Viscosity

- 30~8000cps

- Feed particle size

- 50 ~ 100µm

- Finished particle size

- 5~ 18μm/3 times

- Capacity

- 5kg/h

- Roller working length

- 135mm

- Voltage

- 380V

Overview of QGM-65 three-roll mill

JinKeLian QGM-65 three-roller mill is a wet-type grinding and pulverizing machine with multiple functions such as pulverizing, dispersing, emulsifying, homogenizing, toning, recycling waste, etc. The main components of the QGM-65 three-roller Grinder are three rolls, which are treated with Cr12 steel for enhanced protection. The wear-resistant hardness reaches HRC52°~58°, and the surface roughness can reach 0.2~0.1. QGM-65 three-roll mill is easy to operate, easy to change colors, beautiful in appearance, low in noise, and is used for grinding and refining of various materials.

Applications of QGM-65 three-roll mill

It is suitable for chemical industries such as dyes, inks, plastics, paints, coatings, leather, rubber, lead cores, medicines, food, cosmetics and insulating materials.

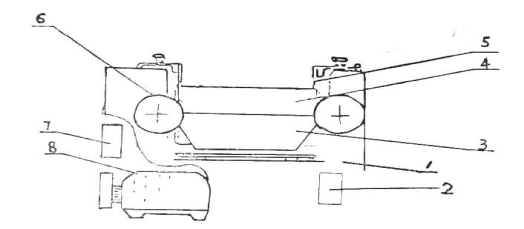

Structural diagram of QGM-65 three-roll mill

(1) Machine body (2) Electrical switch (3) Discharge plate (4) Roller (5) Stop material plate (6) Adjustment system (7) Transmission system (8) Motor.

QGM-65 three-roll mill display

Principle

Raw materials are fed by a natural hopper composed of two middle and rear rollers and two baffle plates, and the opposite and asynchronous rotation of the middle and rear two groups will cause the raw materials to be turned sharply, sheared, and the structural stress plane between the raw material molecules will be destroyed. Through the high-speed secondary grinding of the middle and front rollers, the high-speed and uniform mixing of various raw materials can be achieved.

QGM-65 (roll chrome plating)

QGM-65 (roll chrome plating)