Linshang LS225 industrial grade Coating Thickness Gauge host, probe needs to be purchased separately

SELinShang LS225 Coating Thickness GaugeSPEC

LinShang LS225 Coating Thickness GaugeDetails

LinShang LS225 Coating Thickness GaugePacking list

- SKU

- NB039813

- Power

- 4 1.5V AAA alkalinity batteries

- Display screen

- 240 × 160 dot matrix LCD

- Operating Temperature

- 0℃-50℃

- Total Weight

- 194g

- Complete-built unit size

- 148*76*26 mm

- Storage temperature

- -20℃-60℃

Features

1. Support zero adjustment and multi-point calibration (up to 5 points), equipped with 7 standard sheets of different thicknesses, the curve can be corrected according to the standard sheet or the actual workpiece, so that the measurement data is more accurate.

2. With data statistics function, up to 9 measured values can be stored, and the maximum, minimum, average and variance values of the measured data can be automatically counted.

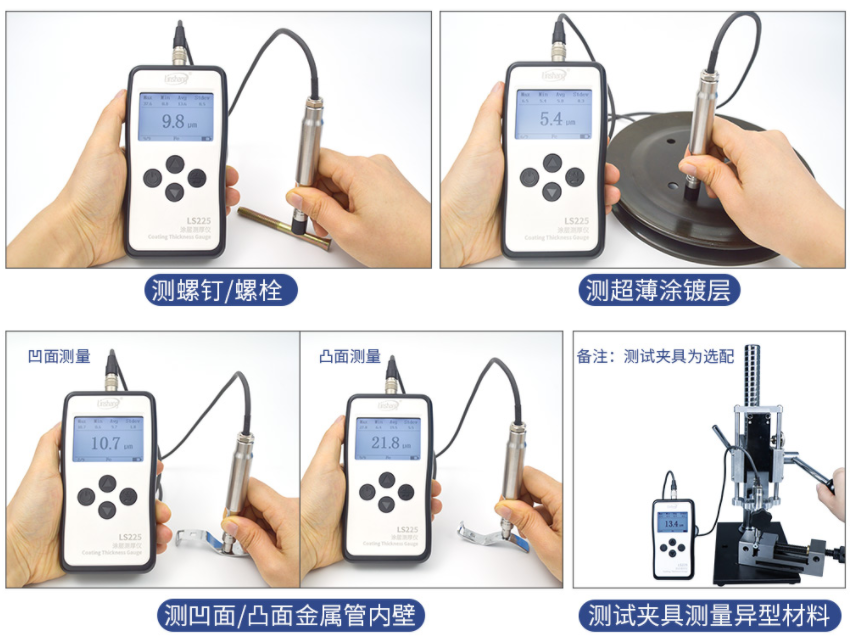

3. Provide special test fixtures for users to purchase, which can make the measurement more convenient and eliminate the measurement errors caused by human factors. (Note: The hand pressure test rack is optional)

4. Support Chinese and English and two kinds of unit switching (μm and mil), can be set to automatically shut down if there is no operation within 1-9 minutes.

Product Structure

Application of LS225+F500 coating Thickness Gauge

LS225+F500 coating Thickness Gauge is widely used in metal processing industry, hardware and other industries. The following pictures are several examples of the practical application of LS225+F500 coating Thickness Gauge (the following measurements are for reference only, not representative of all)

LS225+N1500 Coating Thickness Gauge Test Application

LS225+N1500 aluminum-based coating Thickness Gauge can be used for rapid and non-destructive measurement of non-conductive coating thickness on non-magnetic metal substrates in production inspection, construction acceptance and sales exhibition site, and can be used in aviation, building materials, machinery, chemical industry , Light industry and other industries.

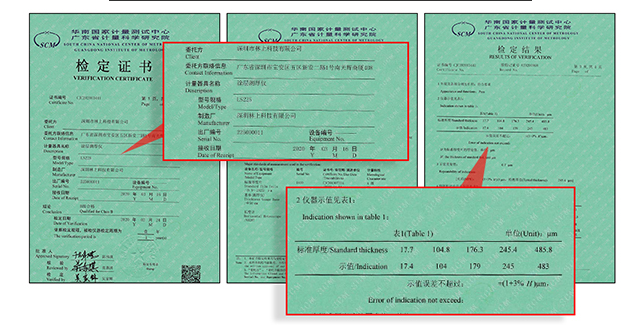

Product qualification meets the standard

GB/T 4956-2003Thickness Measurement of Non-magnetic Coating Layer on Magnetic Substrate--Magnetic Method

DIN EN ISO 2808Determination of film thickness of paints and varnishes

JJG-818-2005Verification regulations for magnetic and eddy current covering thickness measuring instruments

- 1GB/T 44757-2024《Anodizing coating on titanium and titanium alloys》

- 2QJ 990.3A-2011《Inspection methods of coating.Part 3:Measurement of coating thickness》

- 3NF EN ISO 2808-2007《Paints and varnishes - Determination of film thickness.》

- 4GB/T 13448-2019《Test methods for prepainted steel sheet and strip》

- 5JJG 818-2018《Magnetic and Eddy Current M easuring I nstrument for Coating Thickness》

- 6ISO 2808-2019《Paints And Varnishes - Determination Of Film Thickness》

- 7GB/T 4956-2003《Magnetic substrate, nonmagnetic overlay, overlay thickness measurement magnetic method》

- 8GB/T 13448-2006《Test methods for Prepainted Steel Sheet》

- 9ISO 4042-1999《Fasteners -- Electroplated Coatings》

- 10GB/T 4956-1985《Methods of test for chemical resistance of paint films》

LS225

LS225