YIHENG DHG-9051A Lab Drying Oven Power 1000W

SEYiHeng DHG-9051A Drying OvenSPEC

YiHeng DHG-9051A Drying OvenDetails

YiHeng DHG-9051A Drying OvenPacking list

- SKU

- NB003997

- Power

- AC 220V 50Hz

- Temperature range

- RT+10~200°C

- Temperature Resolution

- 0.1℃

- Environment temperature

- +5~35℃

- Input power

- 1000W

- Volume

- 56L

- Interior size

- 350*350*460mm

- Shelf (std.)

- 2pcs

- Temperature fluctuation

- ±0.5℃

- Net Weight

- 58kg

- Gross Weight

- 66Kg

- Packing size

- 670*670*1000mm

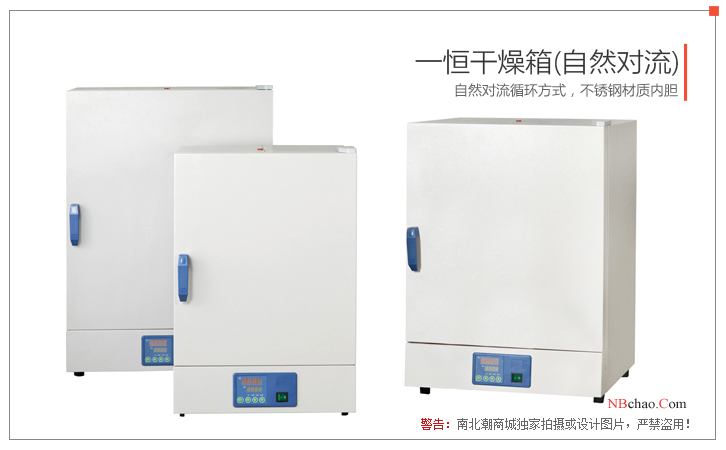

Introduction of DHG-9051A Laboratory Drying Oven

Yiheng DHG-9051A Laboratory Drying Oven is a laboratory desktop Drying Oven used for drying, baking, melting wax, and sterilization. It adopts a microcomputer PID controller with over-temperature deviation protection, and has a timing function to ensure temperature control accuracy. high. The input power of the DHG-9051A Laboratory Drying Oven is 1000W, the effective volume is 56L, and the inner tank size is 350x350x460mm.

Features and advantages

1. Adopt natural convection circulation mode, no noise, and avoid volatilization of samples during the test.

2. The inner tank is made of stainless steel, and the four corners of the inner tank have a semi-circular transition, which is convenient for the cleaning work of the studio.

3. The DHG-9051A Laboratory Drying Oven adopts a microcomputer PID temperature controller with over-temperature deviation protection and digital display, with a timing function, and the temperature control is accurate and reliable.

4. Independent temperature limit alarm system, which will be automatically interrupted when the temperature exceeds the limit, so as to ensure the safe operation of the experiment without accidents. (optional)

5. It can be equipped with a printer or RS485 interface, used to connect a printer or computer, and can record the change of temperature parameters. (optional)

Multi-segment programmable controller (optional)

1. Multi-segment LCD programmable controller, one-screen display of various parameters, and menu-style operation interface can simplify the complicated test process and truly realize automatic control and operation.

2. Parameters such as multi-stage temperature, circulating wind speed, time and heating rate can be set and programmed at the same time, and the gradient control of temperature rise can be carried out, and the temperature can be slowly raised from the initial temperature in the box. Functions such as automatic startup, standby and shutdown can also be preset .

3. It can be programmed with 7 sections and 63 steps, each section has 9 steps, and the setting time of each section is 1-99 hours and 59 minutes.

Optional

1. Independent limit alarm

2. RS232/485 interface and communication software

3. Embedded printer

4. Multi-segment programmable liquid crystal temperature controller

Pictures

- 1GB/T 23850-2024《Sodium perchlorate for industrial use》

- 2JB/T 20033-2011《Hot air circulating oven》

- 3GB/T 13835.4-2009《Test method for rabbit hair - Part 4: Moisture regain - Drying oven method》

- 4GB/T 32710.10-2016《Safety requirements for environmental testing and conditioning equipment—Part 10: Electric gravity convection ovens and forced ventilation ovens》

- 5HG/T 5164-2017《Textile dyeing and finishing auxiliaries - Water-borne polyurethane emulsions for textile coating》

- 6GB/T 5211.3-1985《Determination of volatile matter of pigments at 105℃》

- 7JB/T 5520-1991《Technical conditions for drying oven》

- 8QB/T 1552-1992《Technical conditions for paints coatings for luminaire reflectors》

DHG-9051A

DHG-9051A