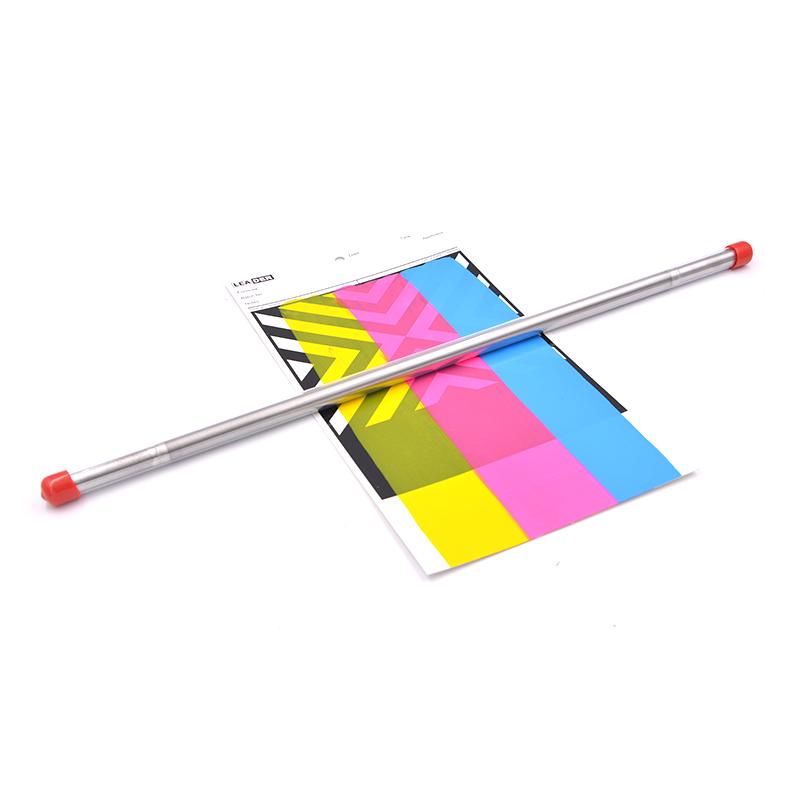

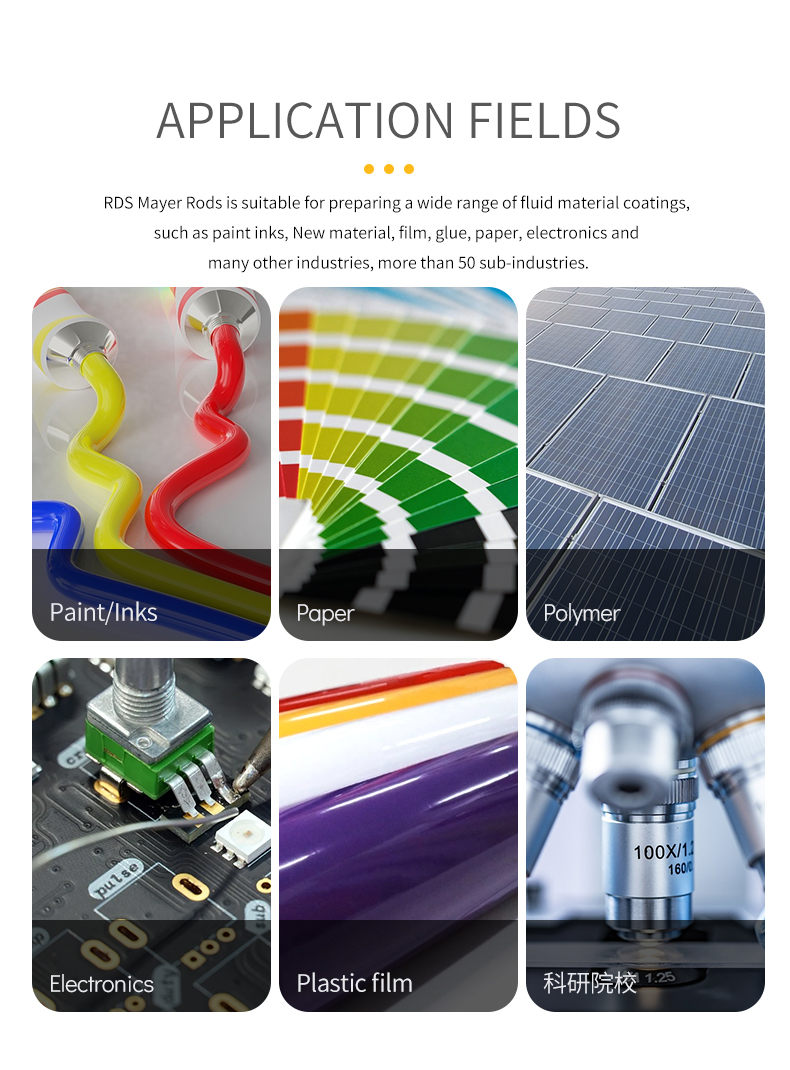

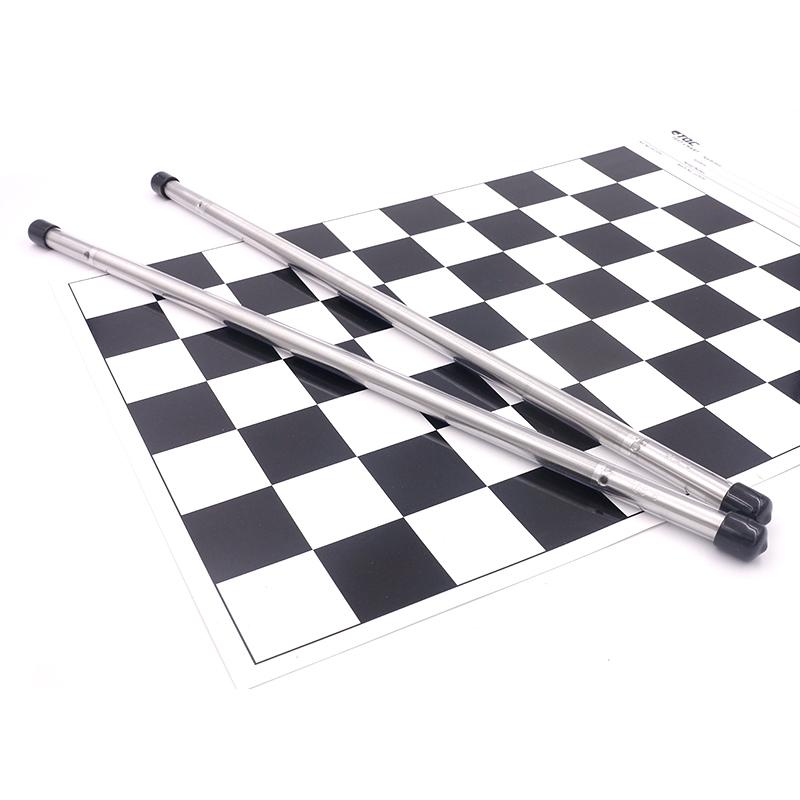

The popular rod number of RDS, the application involves dozens of sub-segments, such as silver-coated nanowires, polymer nano-films. 13.7 micron wet film thickness, this model is wire-wound steel rod, 3/8 inch main rod diameter.

$162.00/piece

PromotionLoading...

Coupon

Model:

Similar products

-

RDS 6 #1/4 "wire-wound Applicator rod film thickness 13.7μm Wire diameter 0.15mm$ 156.00SE

RDS 6 #1/4 "wire-wound Applicator rod film thickness 13.7μm Wire diameter 0.15mm$ 156.00SE -

Pushen XB-I 12μm Wire Bar, Length 240mm$ 98.00SE

Pushen XB-I 12μm Wire Bar, Length 240mm$ 98.00SE -

RDS 6 #1/4 "roller painting rod film thickness 13.7μm rod diameter 6.35mm$ 156.00SE

RDS 6 #1/4 "roller painting rod film thickness 13.7μm rod diameter 6.35mm$ 156.00SE -

RDS 6 #1/2 "steel wire scraping rod, rod Applicator film thickness 13.7μm Wire diameter 0.15mm$ 181.00SE

RDS 6 #1/2 "steel wire scraping rod, rod Applicator film thickness 13.7μm Wire diameter 0.15mm$ 181.00SE -

RDS 6 #3/8 "coating bar No. 6 molded RDS coating bar 13.7 μm$ 162.00SE

RDS 6 #3/8 "coating bar No. 6 molded RDS coating bar 13.7 μm$ 162.00SE

RDS 6# 3/8" Applicator rod 3/8 "SPEC

RDS 6# 3/8" Applicator rod 3/8 "Details

RDS 6# 3/8" Applicator rod 3/8 "Packing list

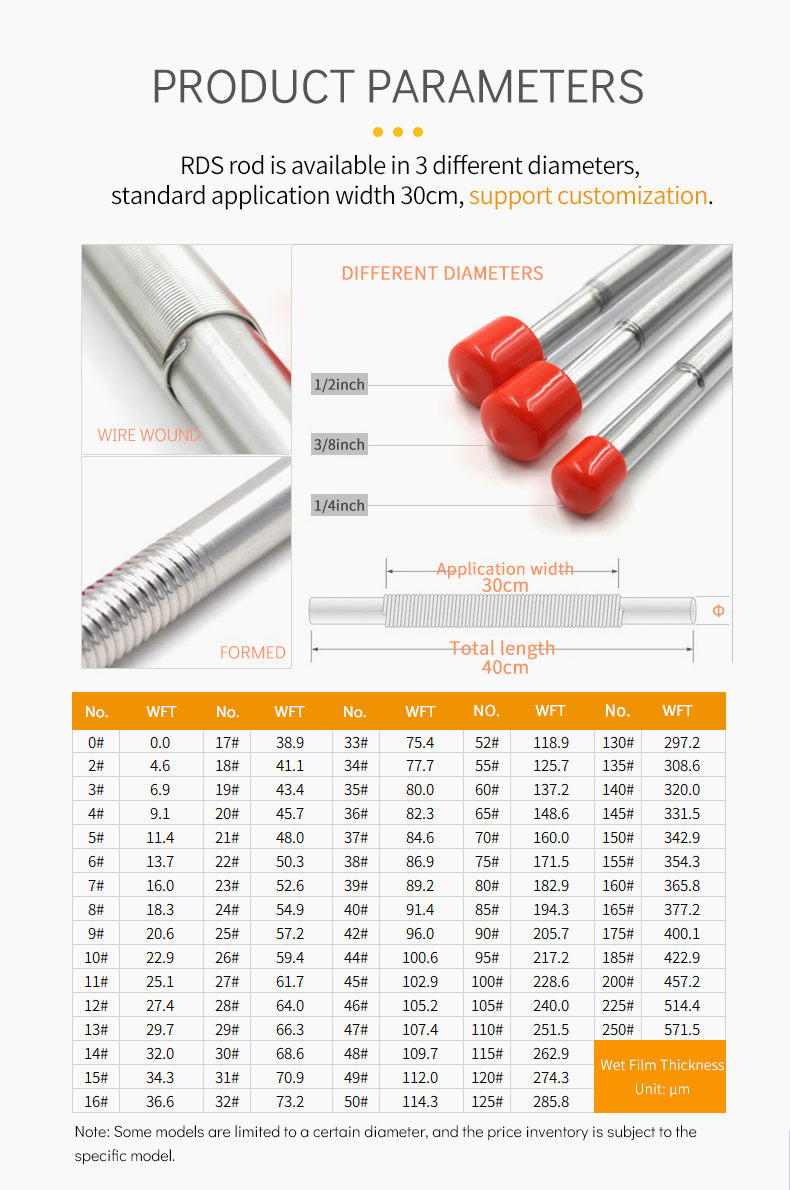

- SKU

- NB000004

- WFT

- 13.7μm

- Production process

- wire-wound

- diameter

- 9.52mm

- Total length

- 400mm

- application width

- 300mm

- Grip Width

- 50+50mm

- material

- stainless steel

- Wire diameter

- 0.15mm

6# 3/8"

Applicator rod 3/8 "

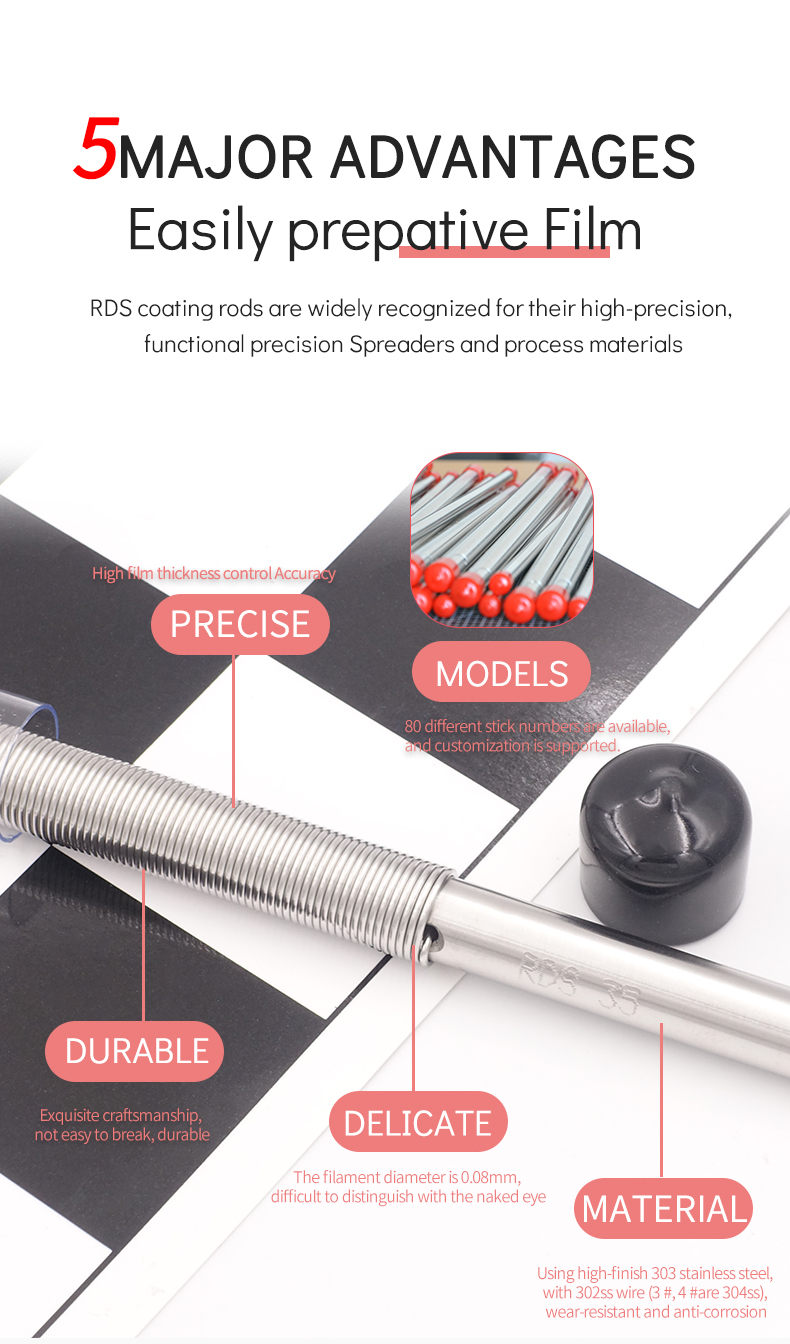

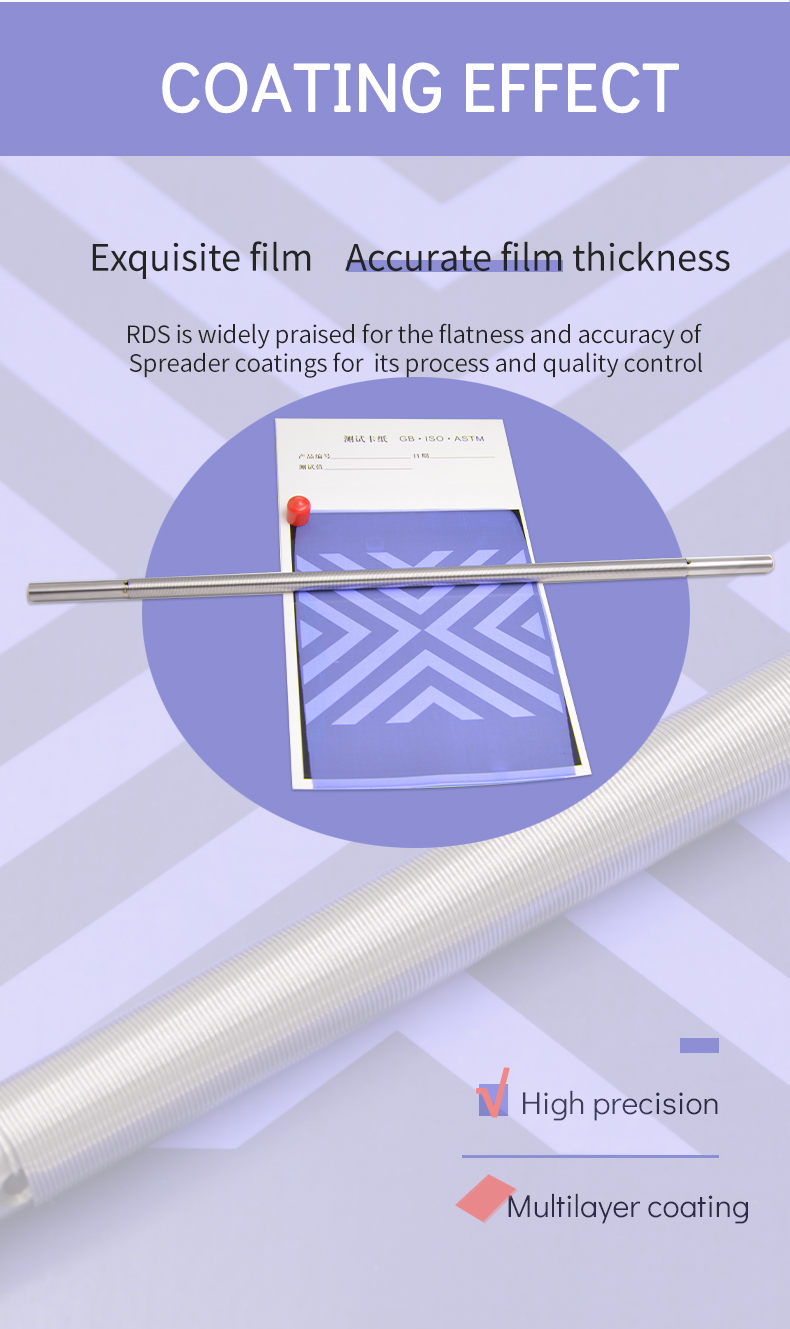

The popular rod number of RDS, the application involves dozens of sub-segments, such as silver-coated nanowires, polymer nano-films. 13.7 micron wet film thickness, this model is wire-wound steel rod, 3/8 inch main rod diameter.

FAQ

QI want to apply a wet-film of about 14 microns. Which bar is suitable?

A

Recommended RDS No. 6 3/8 bar, this specially designed to coat 13.7 micron wet film thickness, wire-wound structure can stabilize the control of Spreader volume, suitable for laboratory precision film.

QWhat is the difference between this wire-wound and the forming type?

A

Wire-wound is the rod with steel wire, the thickness of the steel wire determines the wet film thickness of the rod. The molding type is that the rod uses the extrusion process to squeeze out grooves on it to determine the wet film thickness of the rod

QWhat does "3/8" mean?

A

It is a 6 gauge wire rod from RDS with a diameter of 3/8 inch and a film thickness of 13.7 μm.

QWhat is the purpose of the No. 6 stick? What is the wet film thickness?

A

Hello, Mayer Rods has a wet film thickness of 13.7 microns, and the wet film thickness is the wet Coating thickness of scraping.

QPrinting ink with what number of rod film applicator?

A

Hello, the choice of Mayer Rods should be based on the wet film thickness you scratch. You can use the wet film thickness calculator developed by NBchao to calculate the selection.

QWhat is the reason for the deviation between scraping out and the color difference on the machine?

A

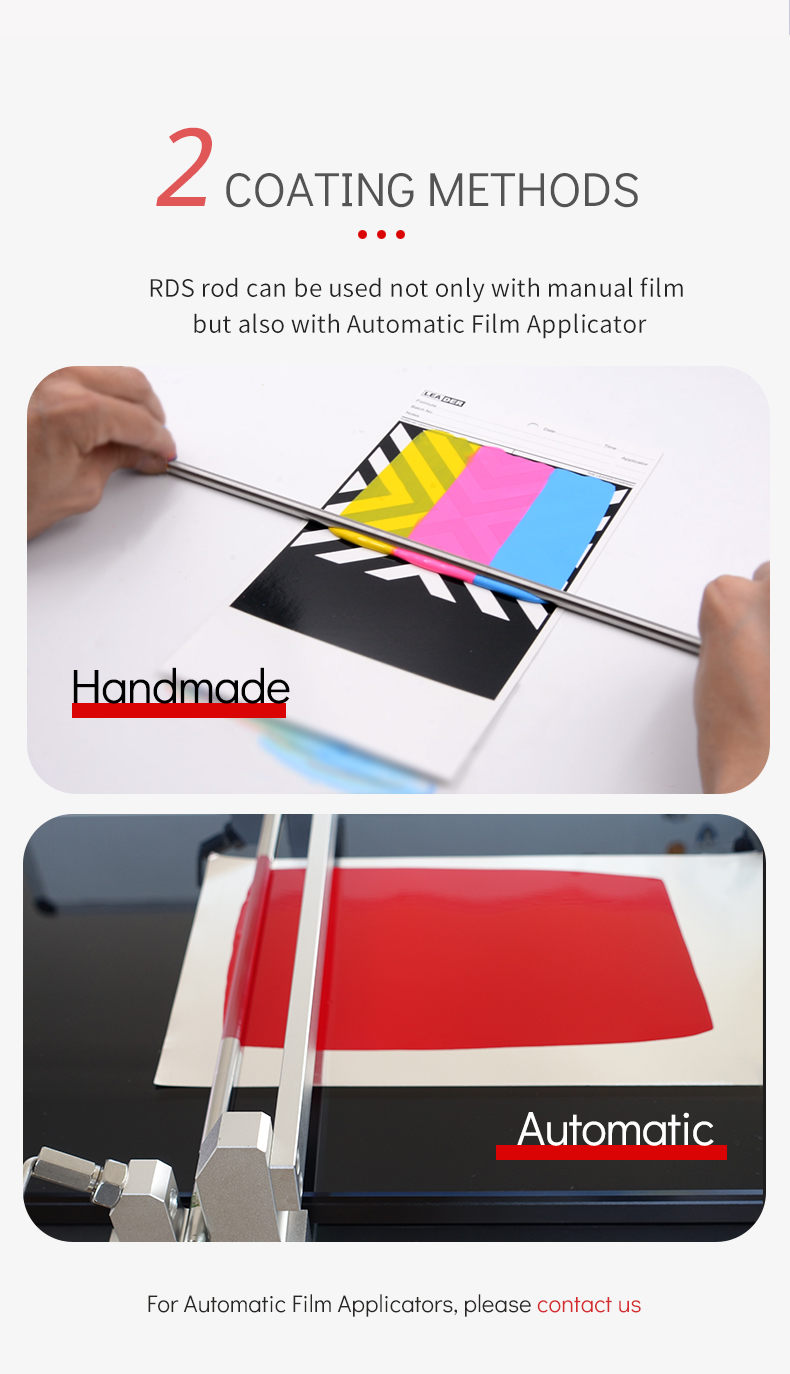

The accuracy uniformity of the proofing film is not only related to the accuracy of the product itself, but also related to the speed and pressure of manual proofing. If you need to avoid errors caused by human factors, it is recommended to consider using the Film Applicator together to control the uniformity of proofing with uniform speed and pressure

QApplicator rod No. 6 inks on BOPP printing film?

A

Yes, the film thickness should be selected for the right rod number, and even if the flatness of the BOPP film can be solved in a centralized manner:

1. Drawdown Plate: This kind of economy, good coating effect

2. Vacuum adsorption Film Applicator: With Mayer Rods, the film thickness can be precisely controlled, and the effect is more.

QIt's all size 6, what's the difference between 3/8 and 1/4?

A

3/8 and 1/4 are the diameter of the rod, in inches. That is, the diameter of one rod is 9.5mm and the diameter of the other is 6.35mm. Miscellaneous is the same.

QDoes RDS6 Mayer Rods have a length of 240mm?

A

No, the experimental wire rods of RDS are all 400mm long.

QGravure ink Colorimetric, 6 rod coated film thickness is how many microns?

A

Hello, 13.7 μm.

Knowledge

- 1Bar Spreader Technology: Principles, Applications and Advantages over Miscellaneous coating methods

- 2Application of Mayer Rods in protective coating prepative

- 3Technical method and application of preparing nanometer silver wire thin films with Mayer Rods

- 4Application of Mayer Rods in Water-based ink Moulding

Standard

- 1GB/T 1727-2021《General methods for preparation of coating films》

- 2GB/T 7044-2022《Colour carbon black》

- 3HG/T 5370-2018《Waterborne coatings for bicycles》

- 4HG/T 3951-2007《Water based colorants for architectural coatings》

- 5GB/T 13217.1-2020《Test method for colour and tinctorial strength of ink》

- 6HG/T 3948-2007《Hot Melt Adhesives for Sanitary napkin & Panty liner》

- 7ASTM D4147-2023《Standard Practice for Applying Coil Coatings Using Wire-Wound Drawdown Bars》

- 8GB/T 13217.1-2009《Test method for colour of liquid ink》

- 9GB/T 13217.7-2009《Test method for adhesion to substrate of liquid ink with tape》

- 10GB/T 21867.3-2008《Pigments and extenders - Methods of assessment of dispersion characteristics - Part 3:Assessment from the change in gloss》

6# 3/8"

6# 3/8"