YIHENG DHG-9030A Desktop Forced Air Drying Oven Stainless steel liner Power 850W

SE-

CHINA DHG-9030A vertical Forced Air Drying Oven circulating Electric Oven 200 ℃/30L$ 325.00SE

CHINA DHG-9030A vertical Forced Air Drying Oven circulating Electric Oven 200 ℃/30L$ 325.00SE -

HUITAI DHG-9030A Blast drying oven temperature control RT + 10~ 250 ℃ Volume 30L$ 366.00SE

HUITAI DHG-9030A Blast drying oven temperature control RT + 10~ 250 ℃ Volume 30L$ 366.00SE -

MODERNER GFX-9030A Forced Air Drying Oven 30L

MODERNER GFX-9030A Forced Air Drying Oven 30L -

MODERNER GFX-9035A Forced Air Drying Oven 20L

MODERNER GFX-9035A Forced Air Drying Oven 20L -

RONGHUA DHG-9030A Electric thermostatic Drying Oven$ 345.00SE

RONGHUA DHG-9030A Electric thermostatic Drying Oven$ 345.00SE

YiHeng DHG-9030A Drying OvenSPEC

YiHeng DHG-9030A Drying OvenDetails

YiHeng DHG-9030A Drying OvenPacking list

- SKU

- NB004010

- Power

- AC 220V 50Hz

- Temperature range

- RT+10~200°C

- Temperature fluctuation

- ±1.0℃

- Temperature Resolution

- 0.1℃

- Temperature Uniformity

- ±3%

- Environment temperature

- 5~40℃

- Input power

- 850W

- Volume

- 30L

- Interior size

- 340*320*320mm

- Dimensions

- 620*530*490mm

- Shelf (std.)

- 2pcs

- Timer

- 1~5999min

- Net Weight

- 27kg

- Gross Weight

- 30Kg

- Packing size

- 780*650*580mm

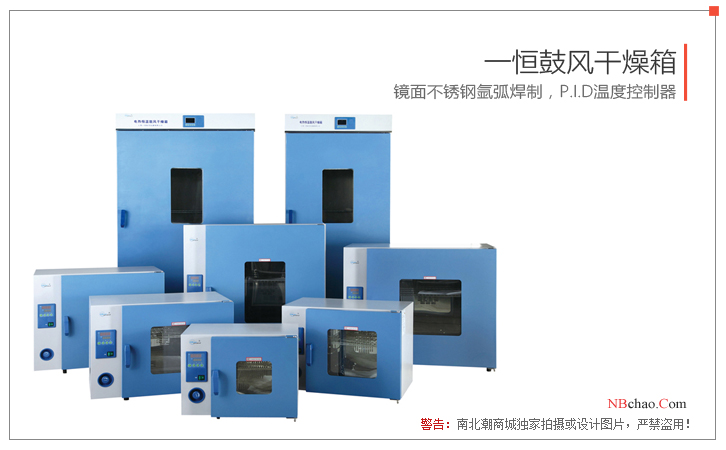

Introduction to DHG-9030A Forced Air Drying Oven

Yiheng DHG-9030A Forced Air Drying Oven is a Forced Air Drying Oven that adopts a hot air circulation system that can operate at high temperatures, which ensures the uniformity of the temperature in the working room, and the temperature fluctuation is ±1°C. The input power of DHG-9030A Forced Air Drying Oven is 850W and the volume is 30L.

Applications

DHG-9030A Forced Air Drying Oven is suitable for drying, baking, melting wax, and sterilization in industrial and mining enterprises, laboratories, and scientific research units.

Features and advantages

1. The inside of the box is made of mirror stainless steel argon arc welding, and the outside of the box is made of high-quality steel plate, which is beautiful and novel.

2. Adopt a microcomputer PID temperature controller with over-temperature deviation protection and digital display, with timing function, and the temperature control is accurate and reliable.

3. The hot air circulation system is composed of a fan that can operate continuously at high temperature and a suitable air duct to improve the temperature uniformity in the working room.

4. Using a new type of synthetic silicon sealing strip, it can run at high temperature for a long time, has a long service life and is easy to replace.

5. DHG-9030A Forced Air Drying Oven can adjust the air intake and exhaust volume in the oven from the temperature control panel.

6. Independent temperature limit alarm system, which will be automatically interrupted when the temperature exceeds the limit, to ensure the safe operation of the experiment without accidents. (optional)

7. It can be equipped with a printer or RS485 interface, used to connect a printer or computer, and can record the change of temperature parameters. (optional)

Optional

1. Multi-segment programmable temperature controller

2. Independent temperature limit controller

3. RS485 interface and communication software

4. Embedded printer

5. Diameter Ф25mm test hole

6. U disk data storage

7. Wireless alarm system (SMS alarm system)

Pictures

- 1SL 144.7-2008《Calibration method of Electric Forced Air Drying Oven》

- 2GB/T 9995-1997《Determination of moisture content and moisture regain of textile--Oven-drying method》

- 3GB/T 6102.1-2006《Test method for moisture regain in raw cotton by oven drying》

- 4GB/T 6978-2007《Test method for the determination of scoured yield of greasy wool - Drying oven method》

- 5GB/T 10514-2012《Determination of free water for nitrophosphate - Oven method》

- 6GB/T 24131.1-2018《Rubber, raw—Determination of volatile matter content—Part 1:Hot-mill method and oven method》

- 7GB/T 30648.5-2015《Paints and varnishes—Determination of resistance to liquids—Part 5: Temperature-gradient oven methods》

- 8SL/T 144.7-2008《Calibration method of Electric Forced Air Drying Oven》

- 9GB/T 32710.10-2016《Safety requirements for environmental testing and conditioning equipment—Part 10: Electric gravity convection ovens and forced ventilation ovens》

- 10GB/T 30435-2013《Electric gravity convection and forced ventilation ovens》

DHG-9030A

DHG-9030A