CHINA NBC-WZZLHY rotorless vulcanizer

SE

HuiTai NBC-WZZLHY Rotorless vulcanizerSPEC

HuiTai NBC-WZZLHY Rotorless vulcanizerDetails

HuiTai NBC-WZZLHY Rotorless vulcanizerPacking list

- SKU

- NB040210

- Temperature control range

- RT+~200°C

- Temperature fluctuation range

- ±0.15℃

- Torque Resolution

- 1/500000

- Torque Accuracy

- 0.3%

- Torque unit

- Nm、 N.cm 、N.inch、kN.m、 kN.cm 、kN.inch、kg.m、 kg.cm 、kg.inch、lp.m、 lp.cm 、lp.inch、gm、 g.cm 、g.inch

- Temperature display resolution

- 0.01℃

- Temperature recovery time after clamping

- < 1.5min

- Temperature unit

- C (degrees Celsius), F (degrees Fahrenheit), K (Kelvin)

- acquisition rate

- 200 times/S

- Supported languages

- English, Simplified Chinese, Traditional Chinese.

- Use standard

- GB/T 16584、ASTM D5289、ISO 6502

- Calculate parameters

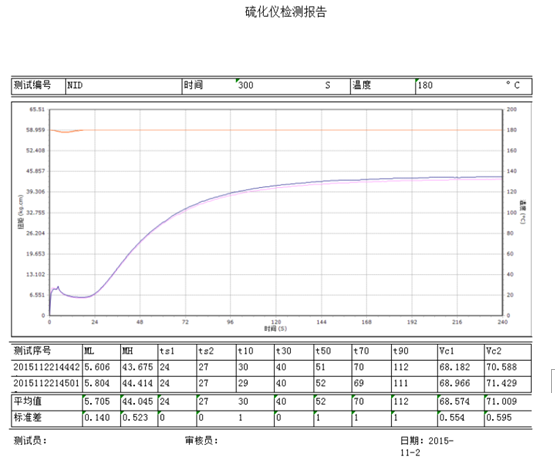

- ts1、ts2、t10、t30、t50、t70、t90、Vc1、Vc2

- software interface

- USB2.0

- Print content

- Date, Time, Temperature, Vulcanized Linear dispersion, Temperature Linear dispersion, ML, MH, ts1, ts2, t10, t50, t90, Vc1, Vc2

Device overview

The rotorless vulcanizer is the most widely used instrument in the rubber processing industry to control rubber quality, rapid inspection and rubber basic research. It provides accurate data for better rubber formula combination, and can accurately measure scorch time, normal vulcanizer time, Vulcanization index and maximum and minimum torque parameters.

main feature

1. The rotorless vulcanizer adopts the latest version of the best software in CHINA, which has the characteristics of fast heating (within 3 minutes) and high temperature control accuracy.

2. The rotorless vulcanizer adopts the alpha closed mold cavity structure, which is in the advanced position in the world.

3. The rotorless vulcanization Tester adopts the excellent Alpha upper force sensor technology: (sensor accuracy reaches 0.001Nm)

4. The rotorless vulcanizer adopts the excellent alpha closed cavity structure, and the rotating cavity and the fixed cavity are sealed by the imported sealing ring, and the structure of the closed cavity is completely different from that of the general open cavity. Its precision and requirements and excellence are incomparable. The repeatability of the closed mold cavity is completely consistent, which is in the advanced position in the world.

Principle

Put the rubber sample into an almost completely closed mold cavity and keep it at the test temperature. The mold cavity has two parts, the upper and lower parts, and the lower part moves back and forth in a small linear motion (oscillating oscillation), and the vibration causes the sample to generate shear strain. , Determining the reaction torque (force) of the sample to the cavity, the magnitude of this torque (force) depends on the shear modulus of the compound.

After the vulcanization test begins, the shear modulus of the sample increases, and the computer displays and records the torque (force) in real time. When the torque (force) rises to a stable value or maximum value or even returns to the state, a torque ( The relationship between force) and time, that is, the vulcanization curve (as shown in Figure 1), the shape of the curve is related to the temperature of the test and the characteristics of the rubber compound.

Application

It is an important testing instrument used by the state to develop new products, research rubber formula, control rubber quality and apply rubber basic research. Widely used in all walks of life of rubber products.

Standards

The rotorless vulcanization Tester meets the requirements of GB/T16584 "Rubber - Determination of vulcanization characteristics with a rotorless vulcanizer", the requirements of ISO6502 and the T10, T30, T50, T60, T90 data required by the Italian standard.

NBC-WZZLHY

NBC-WZZLHY