ShenyangTX W-B75b Wayer Hardness Tester for testing brass tubing with an inner diameter as small as 6mm

SEShenYangTianXing W-B75b Wechsler Hardness TesterSPEC

ShenYangTianXing W-B75b Wechsler Hardness TesterDetails

ShenYangTianXing W-B75b Wechsler Hardness TesterPacking list

- SKU

- NB004044

- Minimum specimen inner diameter

- Φ6mm

- Maximum sample thickness

- 8mm

- range

- 0~20HW (equivalent to 53~ 92HRB) (equivalent to 87~ 109HRF)

- Error of indication

- 0.5HW(5-17HW)

- Repeatability Error

- 0.5HW(5-17HW)

- Weight

- 0.5kg

Introduction to Wei-style Hardness Tester

Shenyang Tianxing W-B75 seriesCopper alloysWei-style Hardness Tester is a special hardness testing instrument for testing the mechanical properties of brass alloys, and the measurement range is as follows0-20HW.W-B75 series copper alloy Webster Hardness Tester is divided into two types: W-B75 Webster Hardness Tester is mainly used for brass tubes and brass strips, Type W-B75B is used to test thin brass tubes with an inner diameter of as little as 6 mm.

W-B75 seriesCopper alloysWei-style Hardness Tester can quickly test the hardness of brass on site, easy to use, one card can be, the hardness value can be read directly, high efficiency, good reliability, in line with CHINA's nonferrous standard YS/T471-2000.

Scope of application

Shenyang Tianxing W-B75 seriesCopper alloysWesley Hardness TesterIt is used to quickly test the hardness of copper alloy pipes, plates and strips. It is particularly suitable for fast, non-destructive piece-by-piece qualification inspection of batches at the production site, sales site or acceptance site.

Features

1. Pressure needle: The pressure needle made of imported special steel materials and new technology has high hardness, good toughness, long life and good interchangeability. The outer packaging imported from Germany provides comprehensive protection for the pressure needle.

2. Pointer assembly: high-strength pointer, long-term use or wrong operation is not easy to bend and deform.

3. Window: high-strength, high-toughness window glass, not easy to break after impact.

4. Handle: forged aluminum alloy material, anodized upper handle, beautiful, wear-resistant, pollution-resistant.

5. Hardness block: use standard Rockwell Hardness Tester and strictly follow the measurement verification procedures for calibration. The number and hardness value of laser etching, and the traceability data can be checked within the validity period. The surface roughness and flatness meet the requirements of the regulations.

6. High quality: fine parts processing, precision machine assembly, and strict quality inspection ensure the high quality of the instrument.

7. Good stability: the full degree point is stable, the correction point is stable, and the pointer has no "crawling".

8. Easy conversion: Through the conversion table attached to the product manual or the "hardness conversion" mobile phone application, the Webster Hardness value can be converted into Vickers, Rockwell, Brinell and other hardness values.

9. Portability: The high-quality portable instrument case and well-fitting buffer sponge provide portability for the W-B75 series Webster Hardness Tester while also protecting it as much as possibleW-B75 seriesWebster Hardness Tester.

Meets standards

● Non-ferrous metals industry standard YS/T 471-2004 "Webster Hardness test method for copper and copper alloys"

●National Metrology Verification Regulations JJG944-2013 "Webster Hardness Tester for Metals"

Standard configuration

Main unit, Wei-style hardness block, small screwdriver, spare pressure pin, correction wrench, instrument case

Common accessories

Presses, Wei-style hardness blocks, window glass

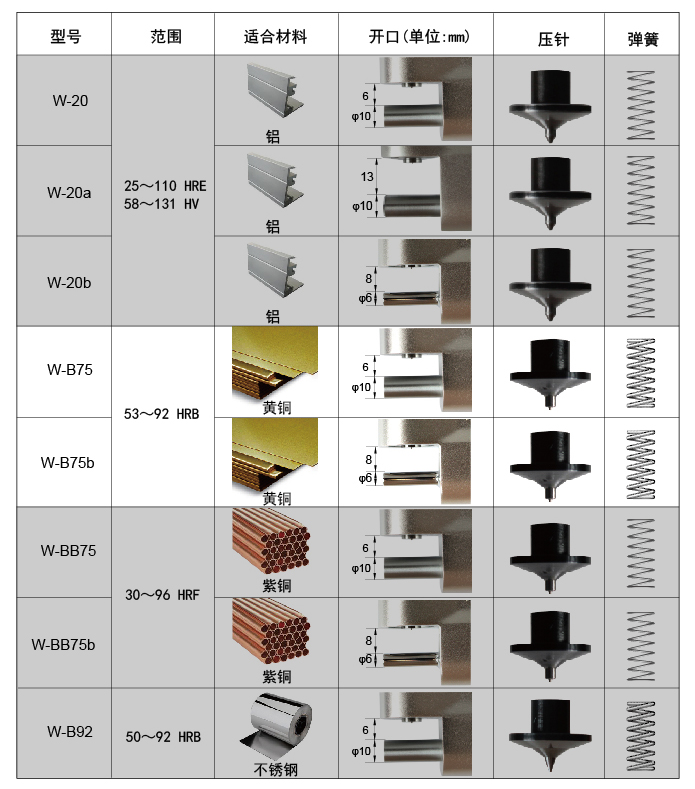

Comparison list of Weiser Hardness Tester models

- 1What are the classifications of commonly used Hardness testing instruments?

- 2How to Measure the Pencil Hardness of Film?

- 3How to measure film hardness

- 4Use and Calibration Steps of Wechsler Hardness Tester

- 5What is the principle of the Vickers test?

- 6Film Appearance performance test film Hardness

- 7How is the Film Hardness Measured?

- 8Film Hardness Pencil inspection method

- 9Purpose and method of coating hardness testing

- 10[Film Properties and Measurements] - Determination of film hardness

W-B75b

W-B75b