TENCAN Powder GQM-8-5L Tank mill Ball mill

TENCAN Powder GQM-8-5L Ball millSPEC

TENCAN Powder GQM-8-5L Ball millDetails

TENCAN Powder GQM-8-5L Ball millPacking list

- SKU

- NB041196

- Ball mill material

- Optional (optional stainless steel, nylon, polyurethane, PTFE, corundum, zirconia, cemented carbide, etc.)

- Dimensions

- 950*660*960mm

- motor

- 220V

- Power

- 1.5KW

- Rotation speed of main roller

- 50-410rpm

- Device Weight

- 106kg

Introduction

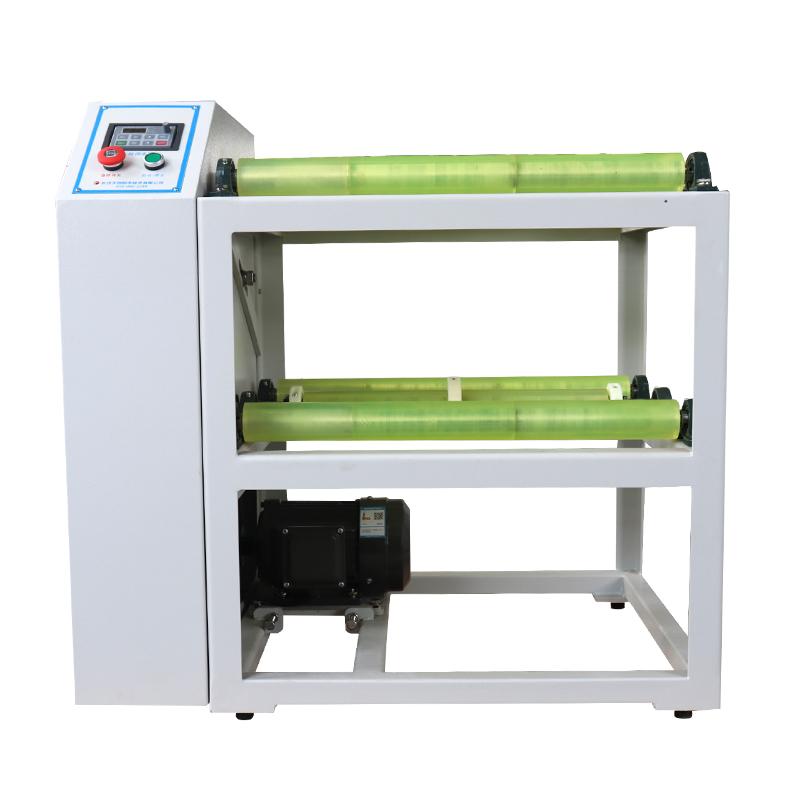

Tank ball mill, also called roller mill, is an ultra-fine grinding and mixing equipment used in laboratories and small batch production. This machine is beautiful and novel, has a compact structure, is easy to operate, has high working efficiency, and has uniform grinding size. It is the preferred equipment for scientific research, teaching, testing, and production. It can be widely used in electronic materials, magnetic materials, biomedicine, ceramic glaze slurry, metal powder, non-metallic minerals, new materials and other industries. The machine has a novel appearance, excellent structure and is easy to use. The rotating speed of the tank of this machine is optimized, and the tank is supported by rubber rollers for better rotation, which allows the media balls in the grinding tank to form a tilting motion to disperse the material and obtain better grinding effects. The tank mill (rolling table machine) is controlled by a digital display time controller. The working time can be set at any time as needed, and it has pause and cumulative Timer Control functions. The operation saves time, effort, and is easy and convenient.

Product principle

When the tank mill ball mill is working, the grinding media and materials in the cylinder are raised to a certain height with the rotation of the cylinder. Due to the action of gravity, they break away from the cylinder wall and fall along a parabola. The impact of the materials on the grinding media and the rolling and sliding of the grinding media produce It is crushed under the action of friction and shear.

Features

1. Multiple samples can be ground at the same time;

2. Can be operated intermittently or continuously;

3. Able to time according to requirements;

4. Suitable for fine grinding of materials with high crushing efficiency;

5. The tank load-bearing rubber roller is made of special materials and is durable.

- 1Introduction and comparison of advantages and disadvantages of 4 kinds of dispersed equipment

- 2Structure, principle and working process of ball mill

- 3Lithium-ion battery separator performance testing scheme [with instrument list]

- 4Comparison of advantages and disadvantages of three physical dispersion methods for ATO slurry

- 55 Ways to Improve Ball Mill Efficiency

- 6Factors Affecting the Grinding Efficiency of Ball Mill

- 7Principle and Application Analysis of Graphite Ball mill

- 8Several common preparation methods of disperse colloids - dispersion method

- 9How to choose the process of nano coating disperser?

- 10Comparison of three different dispersion Applicators

GQM-8-5L

GQM-8-5L