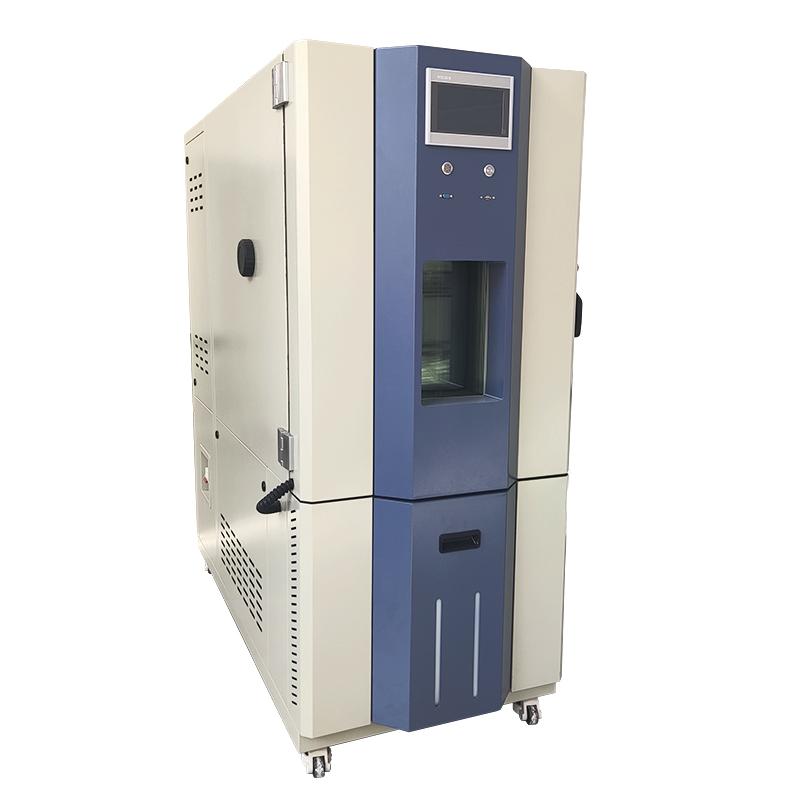

HUDA film Humidity Chamber QT-E702-1000K40 -40 ℃/1000L

SE-

CHINA NBC-1000L-40 Temperature Humidity Cyclic Chamber Paint Panel -40 ℃/1000L$ 5307.00SE

CHINA NBC-1000L-40 Temperature Humidity Cyclic Chamber Paint Panel -40 ℃/1000L$ 5307.00SE -

CHINA NBC-1000L-40 constant temperature and humidity cycle Test Chamber Professional Constant Temperature and Humidity Chamber -40 ℃/1000L$ 5307.00SE

CHINA NBC-1000L-40 constant temperature and humidity cycle Test Chamber Professional Constant Temperature and Humidity Chamber -40 ℃/1000L$ 5307.00SE -

FARI FR-1204-1000 Programmable Constant Temperature and Humidity Tester -40~150 ℃/1000L$ 8999.00SE

FARI FR-1204-1000 Programmable Constant Temperature and Humidity Tester -40~150 ℃/1000L$ 8999.00SE -

KESIONOTS KS-HW1000D High and low temperature Damping heat testing chamber -40~ 150 ℃/1000L$ 4895.00SE

KESIONOTS KS-HW1000D High and low temperature Damping heat testing chamber -40~ 150 ℃/1000L$ 4895.00SE -

ZKHS GDS-010C high-low temperature Humidity Test Chamber -40~150 ℃/1000L$ 11395.00SE

ZKHS GDS-010C high-low temperature Humidity Test Chamber -40~150 ℃/1000L$ 11395.00SE

HUDA QT-E702-1000K40 Programmable Humidity ChamberSPEC

HUDA QT-E702-1000K40 Programmable Humidity ChamberDetails

HUDA QT-E702-1000K40 Programmable Humidity ChamberPacking list

- SKU

- NB041388

- Interior Volume

- 1000L

- Temperature range

- -40~150℃

- Temperature Resolution

- 0.01℃

- Temperature Fluctuation

- ≤±0.5℃

- Temperature Uniformity

- ±2℃

- Humidity control range

- 20~98%R.H

- Humidity Deviation

- ±2%R.H

- Humidity stability

- ±2%R.H

- Humidity Uniformity

- ±3%R.H

- Interior size

- 1000*1000*1000mm

- Dimensions

- 1280mm × 2080mm (including cover) × 1900mm

- Temperature deviation

- ≤±2℃

- Humidity resolution

- 0.1%R.H

- Temperature control Accuracy

- ±0.01℃

- Humidity Control Accuracy

- ±0.1%RH

- Heating rate

- ≧3℃/min

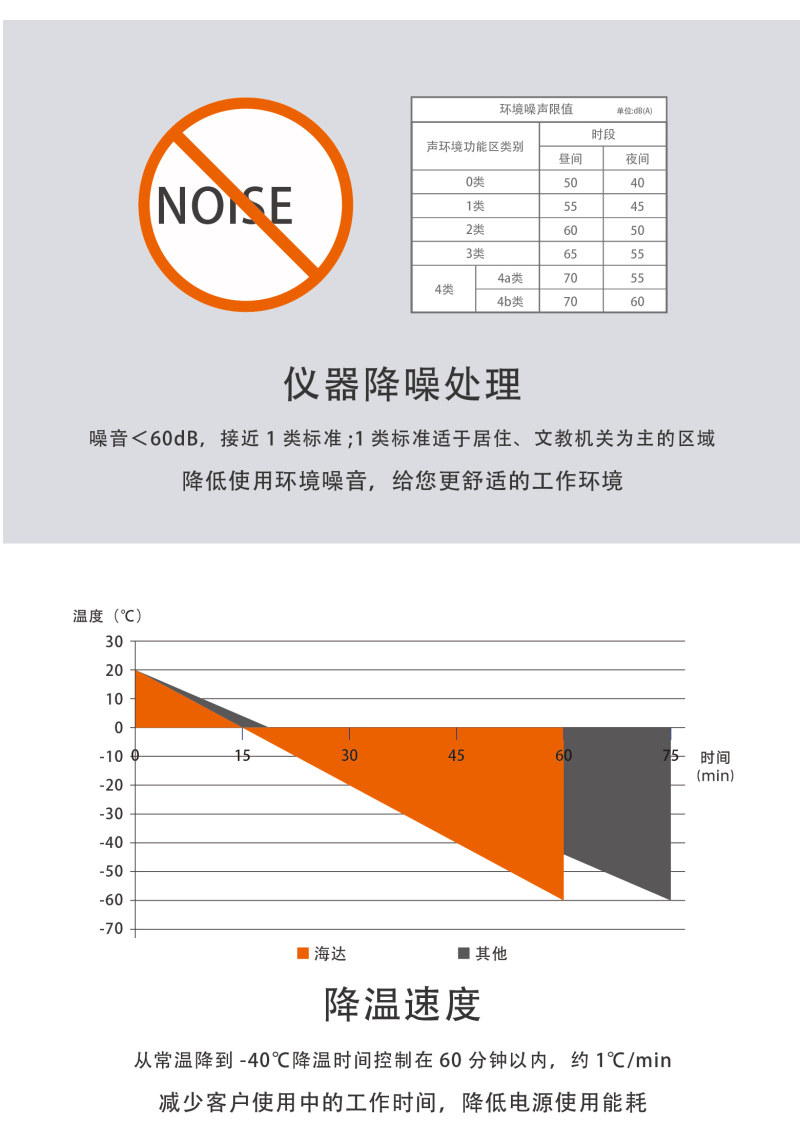

- Cooling time

- ≧1℃/min

- Refrigeration system

- 1 imported French Taikang fully enclosed compressor

- refrigerant

- Environmentally friendly refrigerant R404

- Refrigeration system

- Single stage refrigeration

- Wind circulation

- Centrifugal fan with forced circulation

- Condenser

- finned tube heat exchanger

- Condensation method

- air cooling

- Condenser

- Air-cooled scale condenser, chilled down fan

- Humidification system

- Stainless steel humidifier

- Heating system

- Nickel chromium alloy stainless steel heating device

- Water supply system

- Front-mounted water supply tank, fully automatic water supply system

- Controller

- Taiwan, China Youyi Controller

- Setup method

- Chinese/English interface, touch input

- Operation mode

- Program method/fixed value method

- Set range

- Maximum Temperature range 5 ℃

- Display resolution

- Temperature: 0.01 ℃; Time: 0.1min

- Power-off memory function

- The power failure recovery mode can be set as: hot start/cold start/stop

- input

- Platinum resistance

- Storage function

- Standard 2G SD card recording test data Linear dispersion, can upload and download data, can expand the storage Capacity

- Safety Devices

- Overall equipment overtemperature, fan overheating protection, overall equipment underphase/reverse phase, refrigeration system overload, refrigeration unit overpressure, overall equipment Timer, leakage, operation instructions, automatic shutdown after fault alarm, etc

- Software Operating Environment

- IBM PC compatible machine, CPU above PII, memory above 128M, Simplified Chinese Windows2000 or Simplified Chinese WindowsXP operating system

- Enclosure Material

- Cold rolled steel plate (1.0mm thick)

- Inner box material

- SUS304 #stainless steel plate (1.0mm thick)

- Thermal insulation material

- 100mm polyurethane rigid foam + 100mm high density fiberglass cotton

- Weight

- 529kg

- Rated current

- 28A

- Rated power

- 14kw

- Power

- 380V

- Test hole diameter

- 100mm

- program amount

- Maximum 120 groups, 1 program can be combined from 1 to 99 segments, Capacity: 1200 segments

- Communication interface

- 1. R232/485 communication 2. Can display Linear dispersion, data acquisition 3. Can be used as monitoring and remote Control system

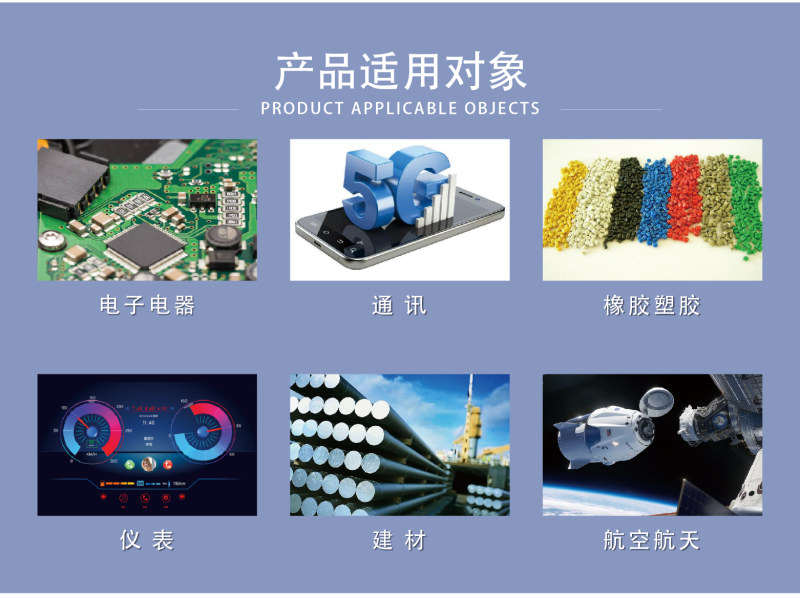

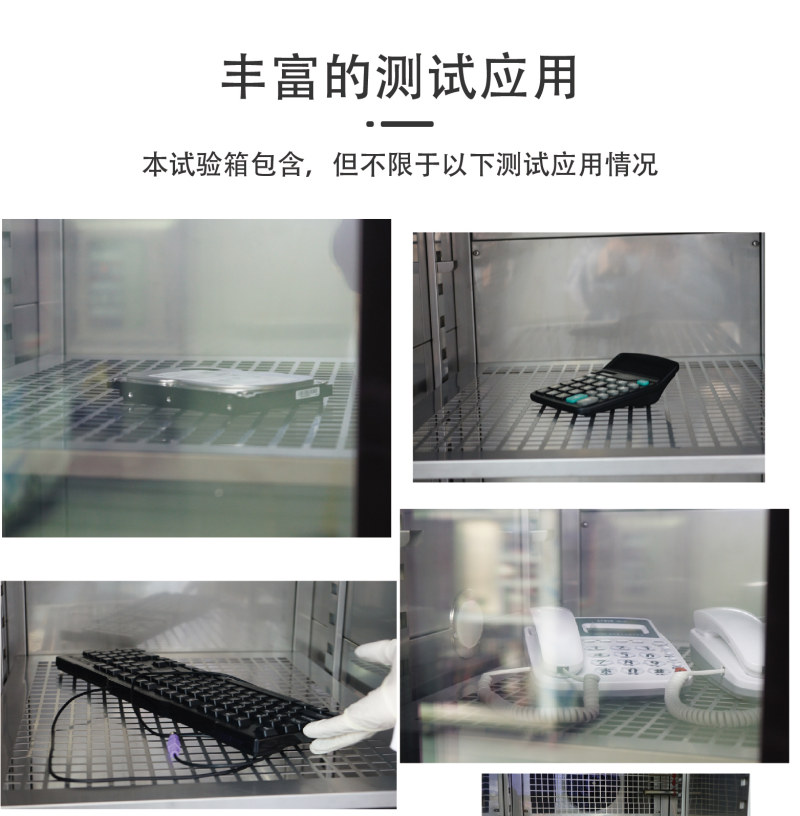

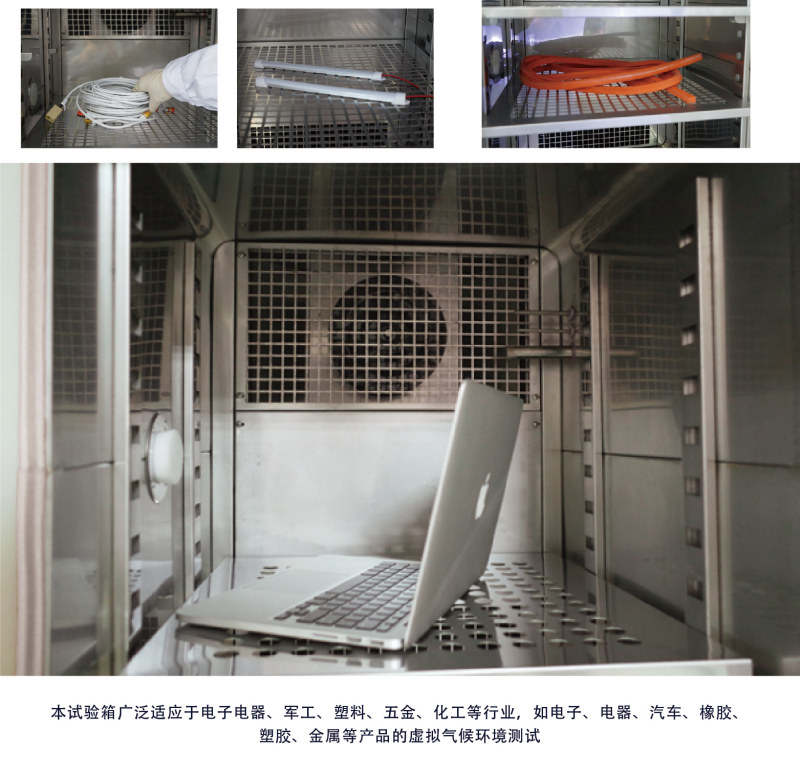

Introduction

This series of products of constant temperature and humidity testing machine is mainly used to simulate the severe high temperature, low temperature or damp heat environment that may be encountered in the transportation, storage and use of electronic instruments, new materials, electricians, vehicles, metals, electronic products, aerospace materials, etc., or in the alternating environment of high temperature, low temperature and damp heat, to test the high temperature, cold resistance, damp heat resistance of materials, accessories or instruments and equipment and the reduction of damage life that may be caused.

Features

(1) Box structure:

1. Inner box material: SUS304# (1.0mm thick) stainless steel plate, which has the advantages of acid resistance, corrosion resistance and easy cleaning.

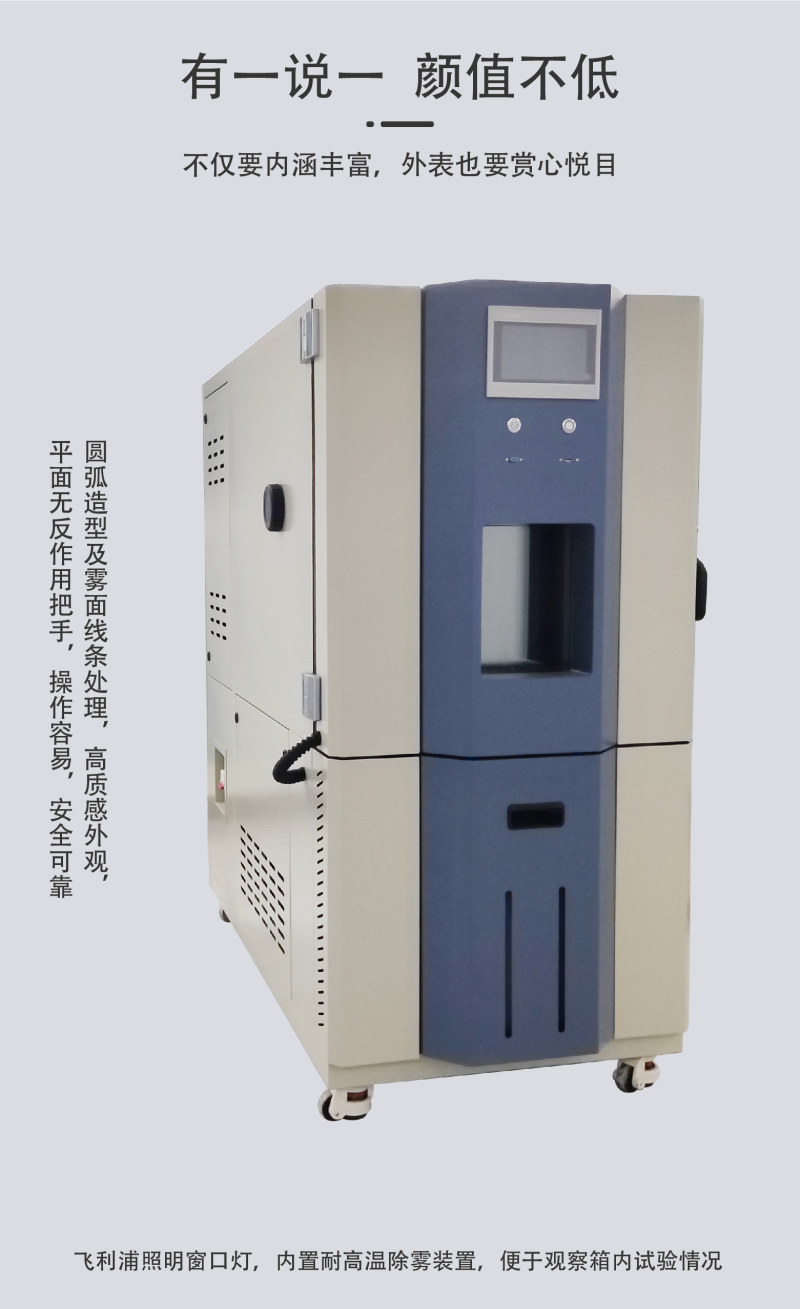

2. Enclosure Material: cold-rolled steel plate baking paint, 1.0mm thickness (dark gray of the box body, sky blue of the box door).

3. Door handle: non-reaction, explosion-proof door handle, easy to operate, safe and reliable.

4. Thermal insulation system: ultra-fine glass fiber is used to fill the insulation area, and the connecting parts of the inner and outer boxes are made of non-metallic high-low temperature resistant materials to effectively reduce temperature conduction; the door is sealed with refined silicone rubber, so that there is no aging and hardening phenomenon under high-low temperature conditions, and the sealing is more reliable; the humidification method adopts isolated humidification.

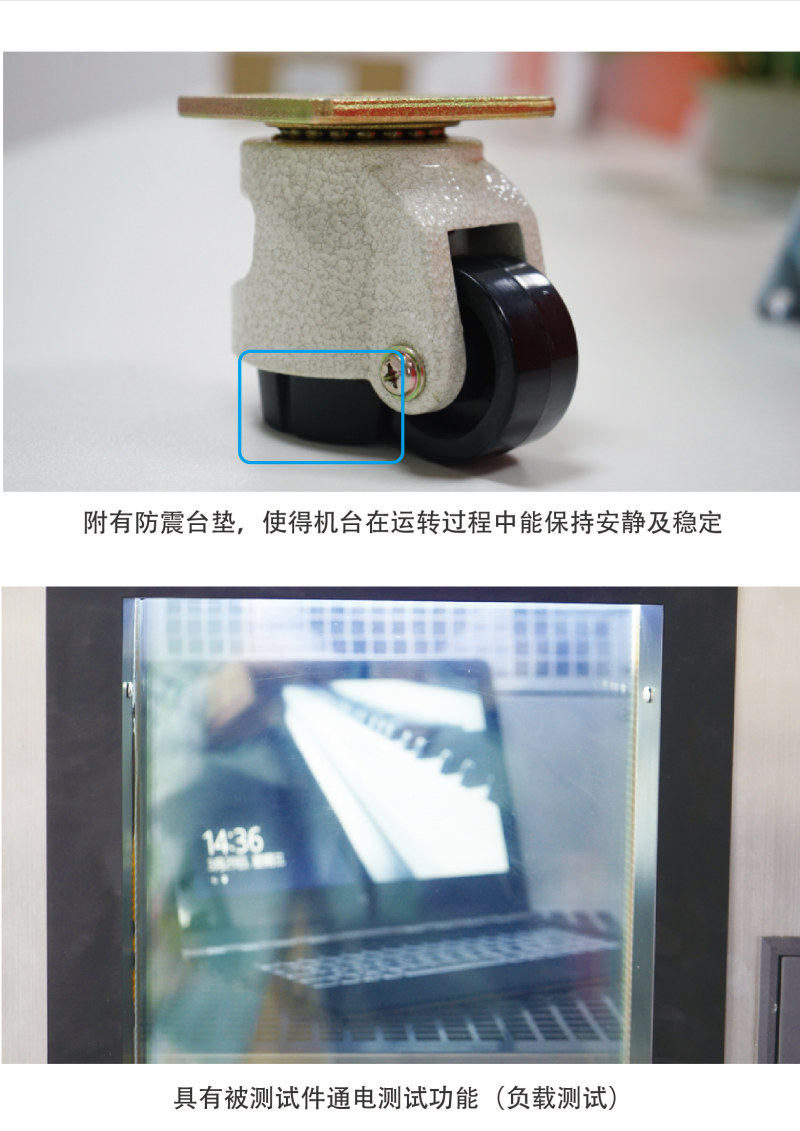

5. Moving and positioning device: high-quality fixable PU movable wheels are installed at the bottom of the machine, which can easily move the machine to the designated position and fix the casters.

6. Sample holder: SUS304# stainless steel punching and bending into a net, easy to use, the spacing between the material racks can be adjusted, two pieces are standard configuration, and the samples are evenly distributed according to the load-bearing ≧ 20kg.

7. Test hole: open a test hole of Φ50mm, and attach the corresponding thermal insulation accessories and special sealing soft plugs

8. Observation window: double-layer vacuum strengthened glass, inner glued sheet conductive film heating and defrosting, clear observation of the test process.

(2) Refrigeration system:

1. The refrigeration unit adopts French Taikang compressor, and uses DuPont environmentally friendly refrigerant (R404a) of the United States, and adopts a two-element low-temperature circuit system design, which is convenient for different compressors to work in different temperature ranges to increase equipment.

2. The temperature and humidity control adopts the P.I.D + S.S.R system with the same channel coordinated control, which has the function of automatic calculation, which can immediately correct the temperature and humidity change conditions, so that the temperature and humidity control is more accurate and stable.

3. The temperature and humidity are all controlled by high-precision controllers, and the relative temperature and humidity performance is accurately set and displayed, with a resolution of 0.1°C

(3) Heating and humidification system:

1. Nichrome alloy high-speed heating wire is used for heating;

2. High temperature completely independent system;

3. The humidity adopts stainless steel pipe, built-in nickel-chromium alloy high-speed heating wire and high-temperature magnesium oxide powder, which has fast reaction and long life.

4. The heating and humidification systems are completely independent, and the humidity has an automatic water replenishment device.

(4) Control system:

1. Adopt precision liquid crystal display programmable temperature controller;

2. Intelligent digital display PID microcomputer temperature control instrument;

3. Touch setting, digital and direct display, humidity directly display percentage, temperature sensor using PT100 platinum resistance Tester.

4. The temperature control adopts the thermal balance temperature control method.

5. The programmable temperature controller with precision liquid crystal display can be used to do program tests, and there can be multiple groups of multi-segment programming operations, fixed values and programs are optional, and the time can be set arbitrarily.

6. The main electrical components of the equipment, such as circuit breakers and AC contactors, are all under the brand of "CHINT", and other electrical accessories are made of domestic (CN) familiar brands.

7. Convenient data processing: it can be connected to a printer or 232 communication interface, with a USB data transfer interface (U disk), displayed by a computer, and printed with temperature, humidity and time curve, which provides a strong guarantee for the storage and playback of data in the test process.

(5) Protection system:

The overall equipment is over-temperature, the fan is overheated protection, the overall equipment is under-phase/reversed-phase, the refrigeration system is overloaded, the refrigeration unit is overpressurized, the overall equipment is timed, and there are other protections such as leakage, operation indication, and automatic shutdown after fault alarm.

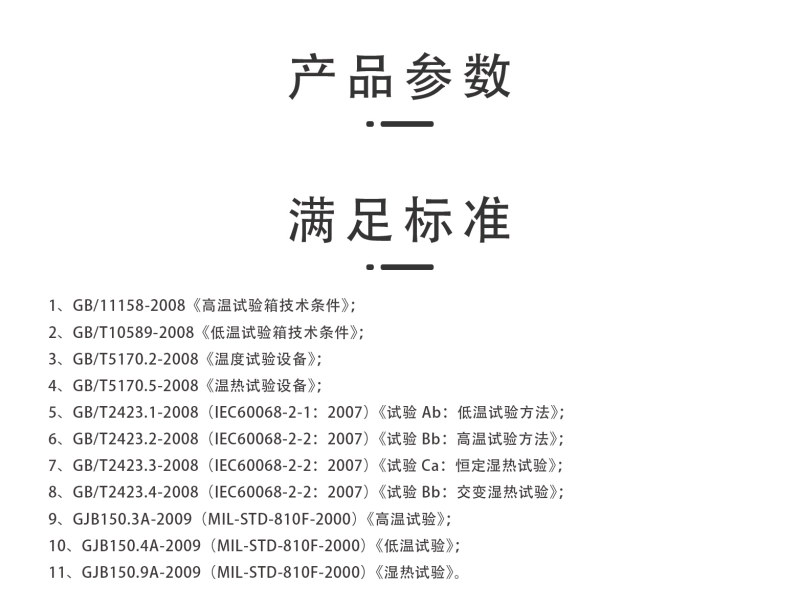

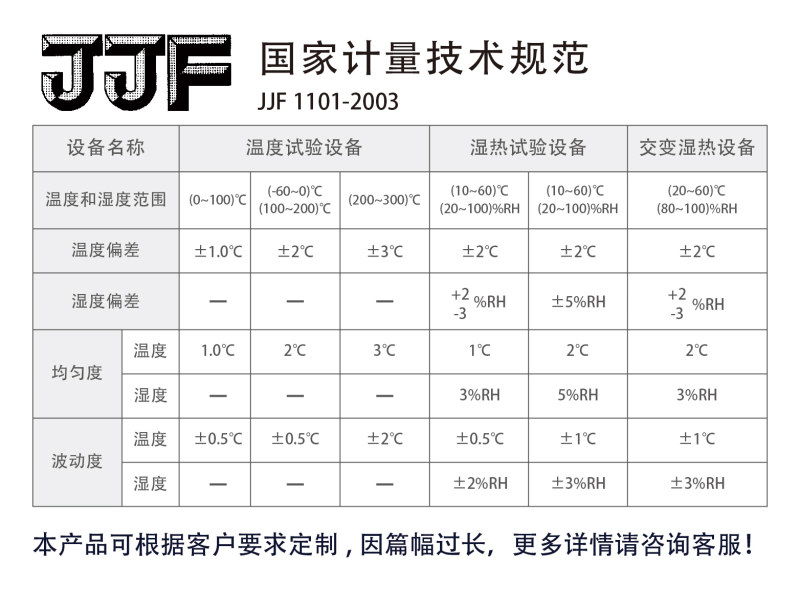

trialstandard

1、GB2423.1-2008/IEC6008-2-1-2007

2、GB/T 2423.2-2008

3、GJB150.3A-2009

4、GJB150.4A-2009

5、GB2423.22-2008

6、GBT 2424.5-2006

7、GB/T 10589-2008

8、GB/T2423.3-2008(IEC68-2-3)

- 1How to solve the problem after the failure of the constant temperature and humidity Test Chamber is found?

- 2How to solve the leakage of large constant temperature and humidity Test Chamber?

- 3Troubleshooting method of constant temperature and humidity Test Chamber

- 4How to do a good job in the regular maintenance and cleaning of the constant temperature and humidity Test Chamber?

- 5What should be paid attention to when using a constant temperature and humidity Test Chamber?

- 6What should be paid attention to in the maintenance of the constant temperature and humidity Test Chamber?

- 7How to use the constant temperature and humidity Test Chamber to save energy and electricity?

- 8Introduction of alarm function of constant temperature and humidity Test Chamber

- 9System introduction of constant temperature and humidity Test Chamber

- 10What is the principle of the walk-in constant temperature and humidity Test Chamber? What are the method steps?

- 1IEC 《Environmental testing – Part 2-78: Tests – Test Cab: Damp heat, steady state》

- 2IEC 《Environmental testing – Part 2-67: Tests – Test Cy: Damp heat, steady state, accelerated test primarily intended for components》

- 3ASTM 《Standard Practice for Heat and Humidity Aging of Oxidatively Degradable Plastics》

- 4GB/T 2423.34-2024《Environmental testing—Part 2:Test methods—Test Z/AD: Composite temperature/humidity cyclic test》

- 5JJF 1564-2016《Calibration Specification for Temperature and Humidity Standard Chambers》

- 6JJF 1270-2010《Calibration Specification for Temperature/Humidity/Vibration Combined Environmental Testing System》

- 7JJF 1101-2019《Calibration Specification for Environmental Testing Equipment for Temperature and Humidity Parameters》

- 8 2058-2023《Calibration Specification for Environment Parameters of Constant Temperature and Humidity Laboratories》

- 9QX/T 16-2020《Calibration chambers for temverature and humiditv instrument》

- 10GB/T 34120-2023《Technical requirements for power conversion system of electrochemical energy storage system》

QT-E702-1000K40

QT-E702-1000K40