HUDA High and Low Temperature Thermal Shock Test Chamber QD-E703-100KS40 Three-Chamber water cooling

SEHUDA QD-E703-100KS40 Hot & Cold Shock climate chamberSPEC

HUDA QD-E703-100KS40 Hot & Cold Shock climate chamberDetails

HUDA QD-E703-100KS40 Hot & Cold Shock climate chamberPacking list

- SKU

- NB041404

- Inner Volume

- 100L

- Liner size

- 500*450*450mm

- Dimensions

- ≈1455*1790*1980mm

- Weight

- 650㎏

- Maximum Power

- 15KW

- Maximum current

- 30A

- Power supply conditions

- AC380V three-phase R, S, T, N + protective grounding

- Allowable Voltage fluctuation range

- 10%

- Allowable Frequency Range

- 50±0.5Hz

- Protective ground resistance

- Less than 4Ω

- Power Supply

- TN-S mode Power or TT mode

- Operating Environment

- The user is required to configure the air or power switch of the corresponding Capacity for the equipment at the installation site, and the switch must independently control the use of the equipment

- Functional requirements

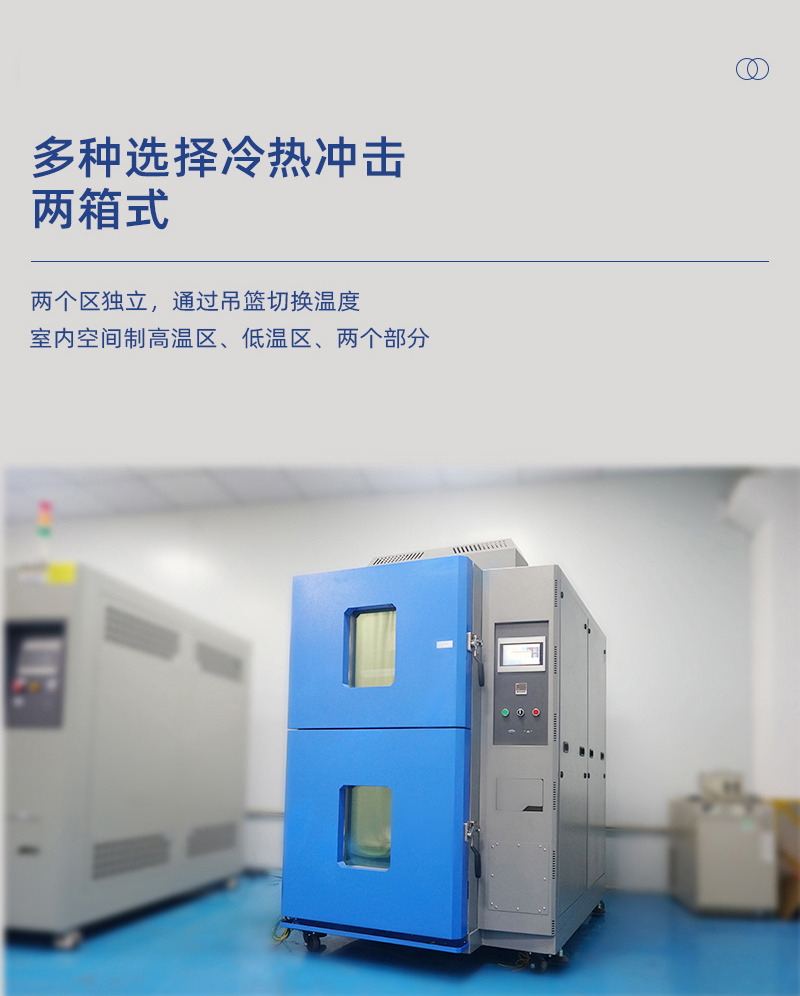

- 1. (air) indoor space cooling and heating; 2. According to the temperature setting, the indoor space reaches the set temperature; 3. It is divided into three parts: heat storage area, cold storage area, and test area; 4. The three areas are independent, and the temperature is switched through the damper

- Operating Conditions

- Ambient Temperature is 0~ + 35 ℃, Relative Humidity ≤ 85%

- High Temperature Impact Range

- RT~170°C

- Low Temperature Impact Range

- RT~-60°C

- Temperature range of test area

- -40~150℃

- Temperature Impact Range

- High temperature: 60 ℃~ 150 ℃; Low temperature: -10 ℃~ -40 ℃; Room temperature: Indoor temperature

- Temperature Resolution Accuracy

- 0.1℃

- Temperature Fluctuation

- ±1℃

- Temperature Uniformity

- ±2.0℃

- Temperature deviation

- ±1℃

- Storage area Heating time

- RT+→170°C≈30min

- Cooling time of cold storage area

- RT+→-60°C≈50min

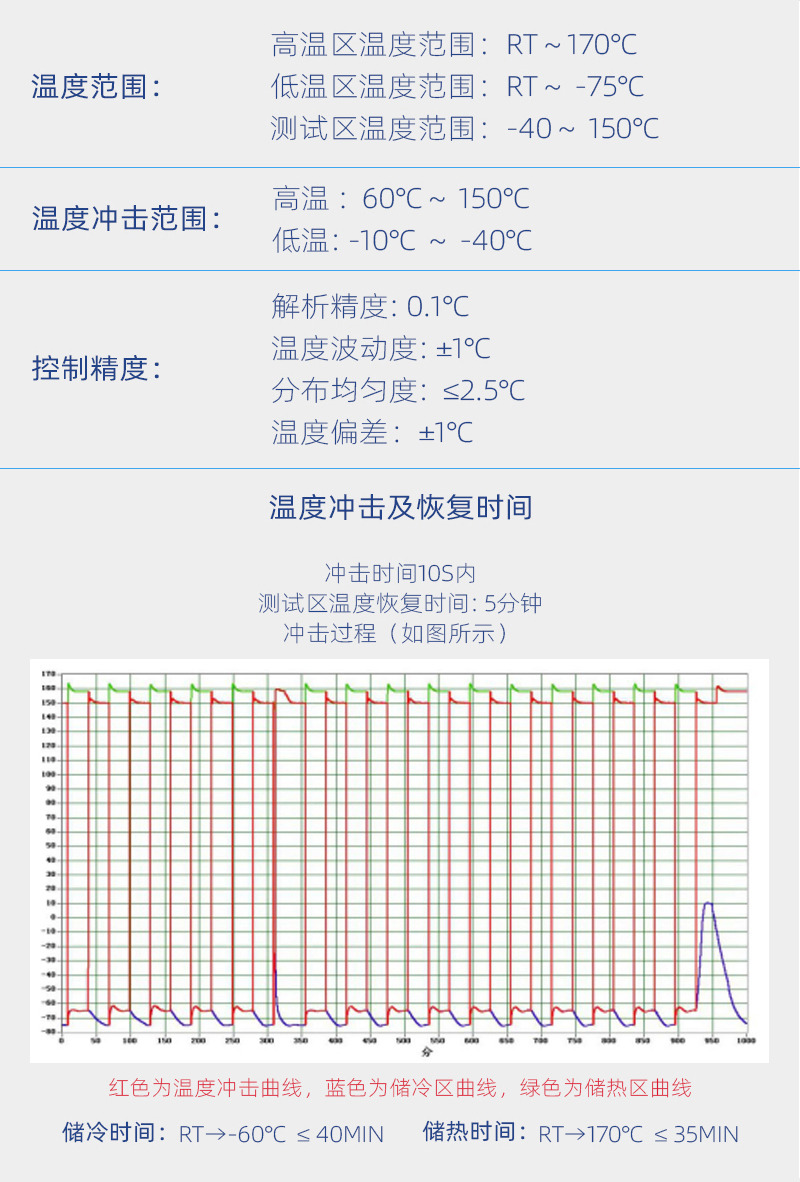

- Temperature recovery time

- 5 minutes

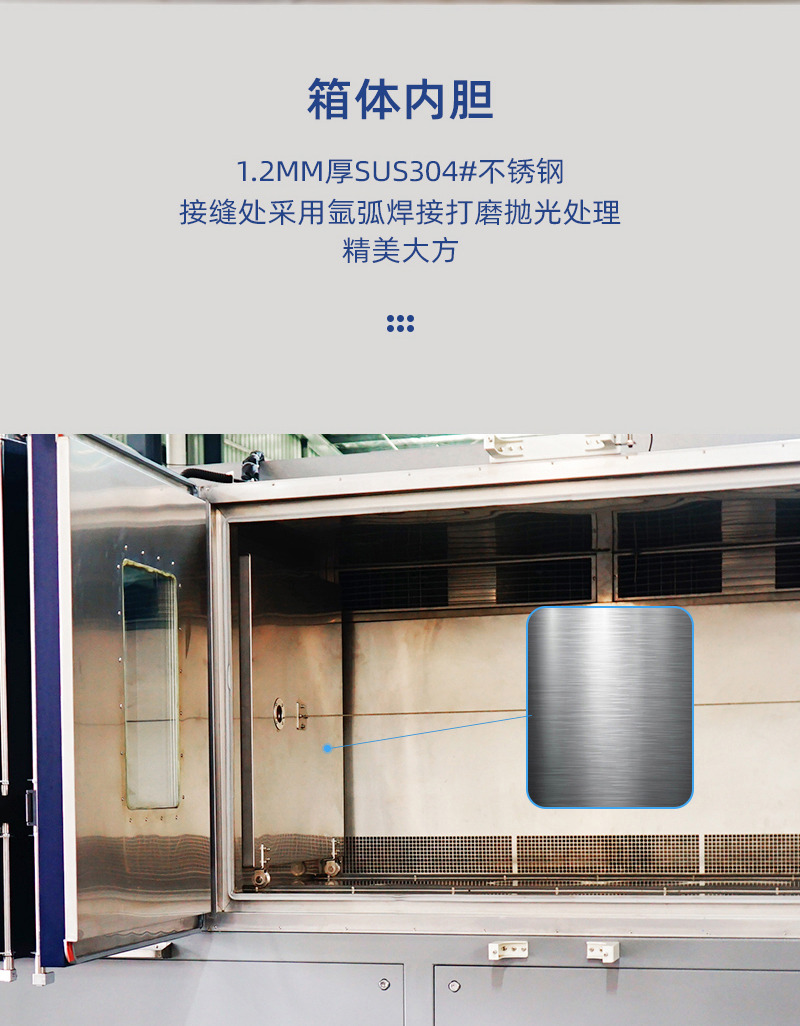

- Liner material

- 304 #stainless steel 1.0mm thick

- Enclosure Material

- Cold plate baking paint 1.5mm thick

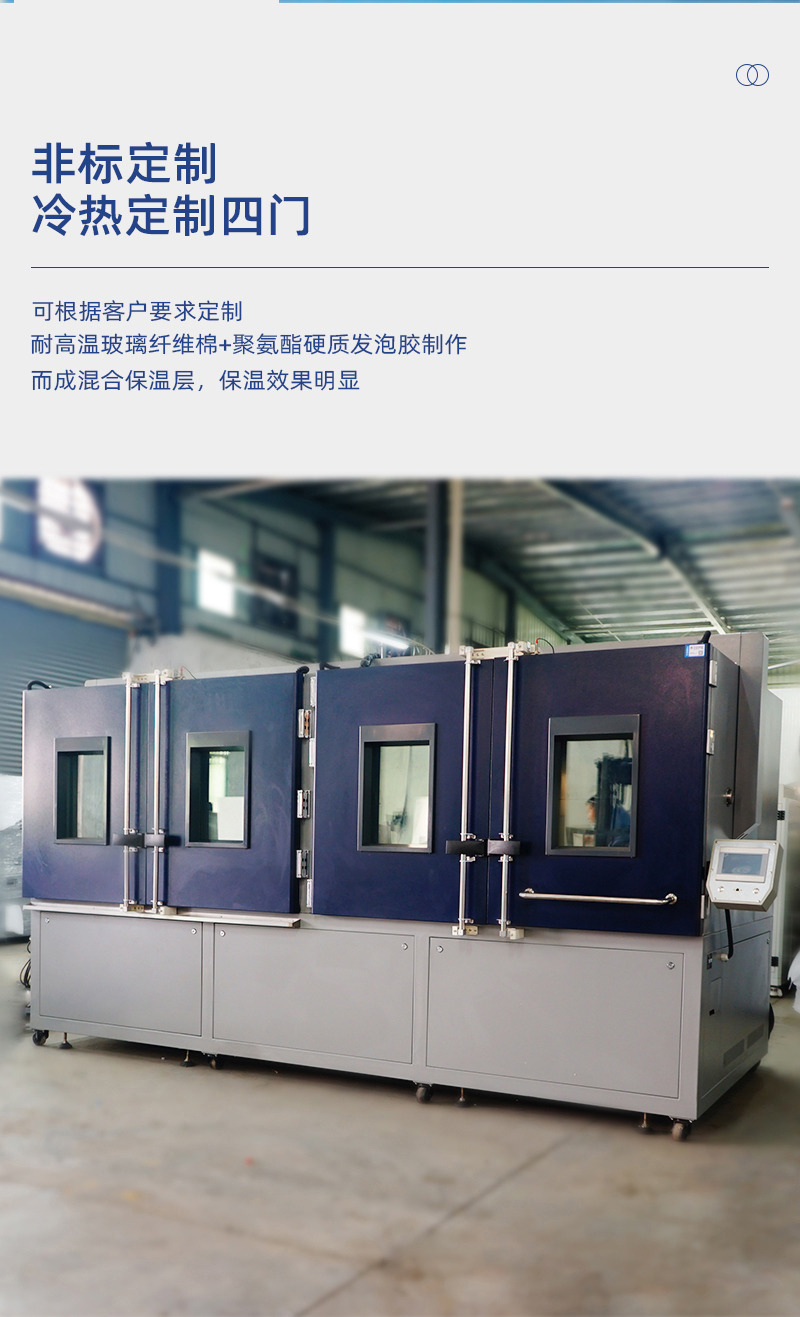

- Thermal insulation material

- Polyurethane foam + fiberglass cotton 100mm thick

- Box door

- Single door, explosion-proof handle

- Lead Hole

- Open the test hole of Φ50mm, and attach the corresponding thermal insulation accessories and special sealing soft plug

- Control mode

- Taiwan, China Youyi LCD touch programmable Controller; main power switch, operation indicator, abnormal indicator, end indicator, defrosting indicator, power indicator, RS-232 communication interface

- Low temperature zone mechanical room

- Evaporator, Circulating Fan, drainage device, cold storage sheet, heating device, circulating wind wheel, volute

- High temperature zone machinery room

- Heating device, Circulating Fan, heat storage sheet, pressure equilibrating port, circulating wind wheel, volute

- Distribution control cabinet

- Total power circuit breaker, Controller, switchboard, cooling fan, over-temperature protector, cylinder, pressure protector, liquid storage tank, water-cooled condenser, refrigeration unit

- Heating system

- Using scale heat dissipation heating pipe P.I.D to control heating to achieve temperature equilibrate

- Refrigeration system

- (Optional) Using Domestic (cn-zh) high-quality chilled down water tower

- Chill down the water tower

- Water circulation cooling use, Flow rate 8 tons/hour

- Test material rack

- Stainless steel SUS #304 grille rack 2 pieces (load-bearing ≤ 20kg/piece)

- Control mode

- Taiwan, China Youyi Controller, control temperature

- Number of programs available

- Maximum 120 groups, can be set to be used in connection between programs

- Command, repeability

- Each command can be up to 9999 times

- RS-232 Communication interface

- Can display Linear dispersion, data acquisition, can be used as monitoring and remote Control system

- U disk memory card

- Configurable 2~ 32G memory card, can record test data for two years, bring your own.

- Operation mode

- Program loop mode

- Set range

- Adjust according to the temperature working interval of the equipment (upper limit + 5 ℃, lower limit -5 ℃)

- Display resolution

- Temperature: 0.1 ℃; Time: 0.1min

- input

- Thermocouple

- Circulatory system

- Low noise multi-wing long axis motor

- Heating system

- Imported nickel-chromium alloy electric heating device

- Heating Control mode

- No touchpoint equal period pulse width modulation, SSR (solid state relay)

- Control mode

- Anti-integral saturation PID, BTC equilibrate temperature control mode (temperature test equipment)

- subsidiary function

- Fault alarm and cause, processing prompt function, power-off protection function, Upper/Lower limit temperature protection function, self-diagnosis and automatic stop function

- Software Operating Environment

- IBM PC compatible machine, CPU above PII, memory above 128M, Simplified Chinese Windows2000 or Simplified Chinese WindowsXP operating system

- Temperature measurement

- T-Thermocouple

- Refrigeration system

- Duplex refrigeration system

- Refrigeration system

- Low temperature compressor imported from Europe

- Refrigeration system

- Water-cooled shell and tube condenser, chilled down water tower

- Evaporator

- finned tube heat exchanger

- Evaporative condenser

- The plate heat exchanger brazed by high temperature copper has small surface area, small energy loss and high heat exchange efficiency

- Throttle device

- Thermal expansion valve, capillary tubing

- Oil separator

- Separate the refrigerated oil droplets mixed with high temperature and high Voltage refrigerant gas discharged from the compressor and return to the compressor curved rail cavity for compressor lubrication and cooling

- refrigerant

- Environmentally friendly refrigerant R404A/R23

- Refrigeration system protection device

- Compressor overheating, compressor overcurrent, compressor overpressure, condensing fan overheating

- Protection device

- Adjustable over-temperature protection, air conditioning channel limit over-temperature, fan, motor overheating relay

- Protection device

- Total Power phase sequence and phase loss protection, leakage protection, overload and short circuit protection, Ambient Temperature protection

- Environmental conditions

- Ambient Temperature should be kept within 0 ℃~ + 35 ℃, Relative Humidity: ≤ 85%

- Storage environment

- Ambient Temperature of the equipment should be kept within 0 ℃~ + 45 ℃; when the Ambient Temperature is lower than 0 ℃, the water remaining in the equipment should be discharged cleanly (the equipment is stopped for a long time) to avoid the water in the pipeline freezing and damaging the pipeline

- Installation site requirements

- The distance between the left and right side panels of the test chamber and the rear side panels shall not be less than 500mm, and the distance between the front and the wall shall not be less than 1000mm

Introduction

The thermal shock testing machine is suitable for aerospace products, information electronic instruments, materials, electricians, vehicles, metals, electronic products, various electronic components, wires, cables, etc. in the environment of high-low rapid alternating environment, to test their performance indicators and quality management.

Meets standards

GJB150.5A-2009 Temperature Shock Test

GB/2423.13-2002 Temperature shock test

GJB360B-2009 Temperature Shock Test

GB2423.1-2008/IEC6008-2-1-2007 Environmental Test for Electrical and Electronic Products Part 2: Test Method Test A: Low temperature

GBT 2423.2-2008 Environmental test for electrical and electronic products Part 2: Test method Test B: High temperature

GBT 10589-2008 Technical conditions for low Temperature Test Chambers

GBT 11158-2008 Technical conditions for high Temperature Test Chamber

Operating Principle

The pre-cooling zone, the preheating zone and the test area are independent, and the three boxes do not need to move the test product through the damper switching, and when the impact is at room temperature, the ambient temperature is introduced into the test space through the blower, and the heat or cooling capacity of the test space is excluded, and the high-low temperature tank damper is closed at the same time; when the impact is low, the high temperature and normal temperature groove damper are closed, and the low temperature tank communicates with the Test Chamber, and the pre-stored cooling capacity is introduced into the Test Chamber instantly; when the impact is at high temperature, the low temperature and normal temperature groove damper is closed, and the high temperature tank communicates with the Test Chamber, and the pre-stored heat is introduced into the Test Chamber instantly. So as to achieve the purpose of rapid alternating temperature

Program capacity and control functions

The number of programs that can be used: up to 120 groups, and the programs can be set to be used in connection

Repeatable commands: each command can be executed up to 9999 times

It has the function of high temperature start/low temperature start/normal temperature start, two or three zone impact

It has the function of pre-heating and pre-cooling, and has the function of skipping and holding in the execution of the program

It has 6 sets of PID parameter settings

It has the function of power-off program memory, automatic start and continuous execution of the program after resuming power

It has the function of temperature waiting timer

Data acquisition, export, view graphics function

It has the function of scheduled start and shutdown

It has the function of adjusting the date and time

Button and screen lock function

Used for automatic cyclic impact or manual selective impact

Fault medical record table display function

The screen can be backlit adjusted, and the backlight time can be set

. PID automatic calculation and FUZZY control

Screen display function

Adopt man-machine dialogue mode, touch input and control

The actual (PV) value of the temperature setting (SV) is displayed directly

It can display the execution program number, segment, remaining time and cycle times, and running time

The status of the execution program action is displayed

. The language conversion can be switched between Traditional Chinese and English

. 7-inch LCD color display

Safety protection device

Refrigeration system: compressor overheating, compressor overflow, compressor overpressure, condensing fan overheating

Test chamber: adjustable over-temperature protection, air conditioning channel limit over-temperature, fan, motor overheat relay

Others: Total Power Phase Sequence and Phase Loss Protection Leakage Protection Overload and Short Circuit Protection Ambient Temperature Overload Protection

Environmental conditions: The ambient temperature of the equipment should be kept within 0°C~±35°C Relative temperature: ≤85%

1. Requirements for storage environment

1) The ambient temperature of the equipment should be kept within 0°C~±45°C

2) When the ambient temperature is lower than 0°C, (the equipment stops for a long time) the water stored in the equipment should be discharged cleanly, so as to avoid the water in the pipeline from freezing and damaging the pipeline

2. Requirements for installation site

1) Please confirm the size required for the installation of the equipment

2)The distance between the left and right sides of the Test Chamber and the rear side wall plate shall not be less than 500mm, and the front distance shall not be less than 1000mm

3)When the equipment is running, enter the door, passage, elevator, etc., whether it can be entered, so as not to affect the progress of your company's project

controller

1) Imported LED digital display (P, I, D+S, S, R.) microcomputer integrated controller

2) Adopt human-computer interaction mode and touch input to allow users to quickly get started

3) The number of programs that can be used: up to 120 groups

4) Repeatable commands: each command can be executed 9999 times

5) Time setting: 0~99 hours 59 minutes

6) The graphical curve can be displayed in real time when the program is executed

7) Display content: temperature setting (SV), actual (PV) value, execution period, program curve execution function, running time, number of stages, running time, remaining time, fault status and failure time

8) There is a function of skipping files and holding during program execution

9) Language selection: You can switch between Chinese and English

10) The production of the program adopts the dialogue type, with editing, clearing, and other functions

11) With 3 sets of time signal output control (can control the DUT ON/OFF action)

12) It has 4 sets of PID parameter settings

13) RS-485 interface

14) It has the function of appointment start + appointment shutdown

15) When the machine fails, the fault screen will be displayed and the buzzer will sound loudly

16) It has the function of power-off program memory, automatic start and continuous execution of the program after resumption

17) USB storage function: backup internal parameters, program setting, operation curve recording, U disk memory

Main accessories and origin

| serial number | Origin | Model brand | The name of the accessory |

| 1 | France | Taikang | Compressors (2 units) |

| 2 | CHINATaiwan, CHINA | Youyi | controller |

| 3 | CHINATaiwan, CHINA | CHINT | Contactors |

| 4 | CHINATaiwan, CHINA | Pine poplar | sensor |

| 5 | Denmark | Danfoss | desiccator |

| 6 | Denmark | Danfoss | High Voltage protector |

| 7 | Japan | Heron Palace | Solenoid valves |

| 8 | Denmark | Danfoss | Oil separators |

| 9 | CHINATaiwan, CHINA | Rain Field | Circulating fan motor |

| 10 | CHINATaiwan, CHINA | Vad | Heater (Nichrome) |

| 11 | CHINATaiwan, CHINA | Guoxin | heat exchanger |

| 12 | CHINATaiwan, CHINA | Yongqiang | evaporator |

| 13 | CHINATaiwan, CHINA | Shang Yi | Circulating wind wheels |

| 14 | United States | Emerson | Shock-resistant hose |

| 15 | CHINATaiwan, CHINA | Zhuo Yi | Solid state relays |

| 16 | CHINATaiwan, CHINA | Yongqiang | condenser |

| 17 | United States | R404a | Refrigerant DuPont |

| 18 | Chinese | R23 | Refrigerant DuPont |

| 19 | CHINATaiwan, CHINA | CHINT | Thermal relays |

| 20 | CHINATaiwan, CHINA | CHINT | AC contactors |

| 21 | CHINATaiwan, CHINA | Yongqiang | blister |

| 22 | CHINATaiwan, CHINA | Guoxin | Plate exchanger |

| 23 | Japan | Omron | Miniature relays |

| 24 | Denmark | Danfoss | Filter driers |

| 25 | CHINA | Liangling | Cooling water towers |

- 1What is the difference between the two-box thermal shock Test Chamber and the Three-Chamber thermal shock Test Chamber?

- 2Explanation of the correct operation of the hot and cold shock Test Chamber [including eight and a half minutes of video demonstration]

- 3Working Principle, Failure and Application of Thermal and Cold Shock Test Chamber

- 4Precision heat & cold shock testing device

- 5Principle, Application and Selection of Main board Thermal Shock Test Chamber

- 6Thermal Shock Test Chamber for printed circuit boards

- 1GB/T 7991.3-2021《Test method of viterous and porcelain enamels—Part 3:Determination of resistance to thermal shock》

- 2GB/T 2423.22-2012《Environmental testing - Part 2: Tests methods - Test N: Change of temperature》

- 3GJB 150.5a-2009《Laboratory environmental test methods for military materiel - Part 5: Temperature shock test》

- 4GJB 150.5-1986《Environmental test methods for military equipments Temperature shock test》

- 5GB/T 2423.22-2002《Environmental testing for electric and electronic products- Part 2:Test methods Test N :Change of temperature》

QD-E703-100KS40

QD-E703-100KS40