SITA dynamic interfacial Tension Tester with model 2PEEK production capillary tubing

SITA Pro Line t15 Surface TensioMeterSPEC

SITA Pro Line t15 Surface TensioMeterDetails

SITA Pro Line t15 Surface TensioMeterPacking list

- SKU

- NB041824

- test principle

- Bubbling

- Surface tension Measurement Range

- 10~100mN/m

- Test Accuracy

- 0.1mN/m

- Repeatability

- 0.5mN/m

- Bubble life time:

- 15 milliseconds -20 seconds, Accuracy 1ms, the instrument can preset 3 bubble times, and measure the liquid surface tension within 2 minutes

- Measuring temperature automatically

- Measuring temperature range: 0-100 ℃, reading Accuracy 0.1 ℃, Accuracy 0.1 ℃

- Maximum temperature deviation:

- 0.3K

- Bubbling device

- Built-in small air compressor and millisecond air valve, realize bubbling in liquid from capillary tubing, and precisely control bubble life.

- Probe length

- 68mm

- Reading method

- digital display

- Temperature transducer length

- 68mm

- Capillary tubing material

- PEEK, high temperature, acid and alkali chemical corrosion;

- Suitable viscosity range:

- Below 2000cps;

- Data storage

- The fuselage can store 25 sets of data.

- Software and interface

- With computer connection and data processing software and USB interface; the software can present and compare data in chart form.

- Adjustment

- Can be automatically corrected by distillation water.

- Weight

- 270g

- shell

- Anti-splash sealing shell, acid and alkali resistance.

- Dimensions

- 75*168*35mm

product description

The German SITA column surface tensIon Meter can measure the dynamic and static surface tension of liquids, monitor the quality of the bath liquid during the cleaning process, and establish a good foundation for R&D and cleaning processes to obtain high-quality results. Analysis tower SITA fully automatic dynamic and static surface tensIon Meter SITA Pro Line t15 surface tensIon Meter product research and development in inkjet ink, coating ink, additives, cleaning agents, active agents, electroplating solutions, daily chemical products, alcohol, and petroleum industries , plays a very important role in controlling the cleaning effect of precision electronic workpieces.

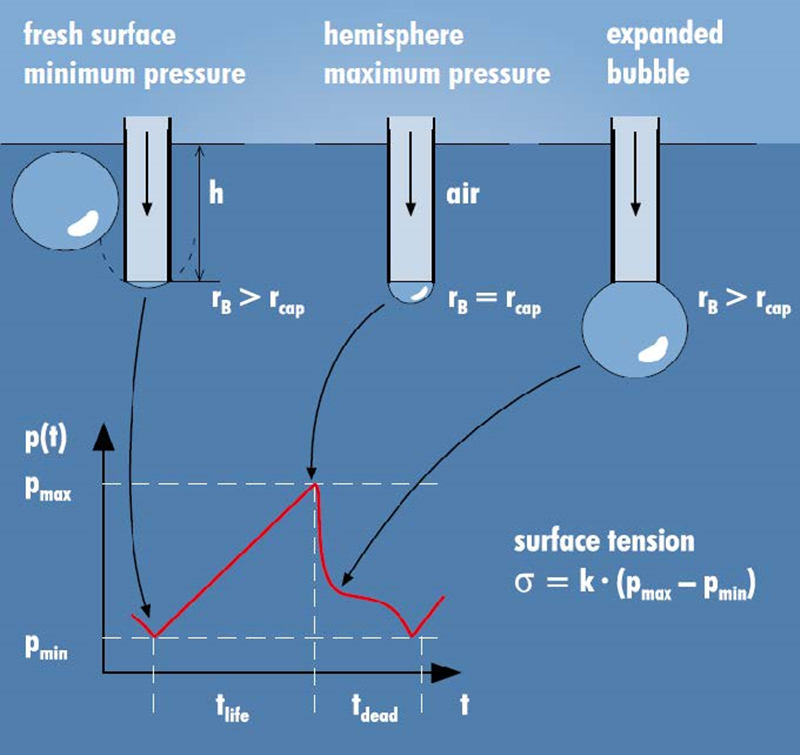

Principle

The bubble pressure method is used to measure the dynamic and static surface tension of liquids without the need to precisely control the capillary immersion depth. The measurement accuracy is high and the operation is flexible. Air is blown through the capillary tube into the liquid to be measured. The pressure inside the bubble continuously changes as the bubble radius changes. Therefore, surface tension can be calculated from the difference between the maximum and minimum pressure values. The instrument can be automatically calibrated using pure water.

Features

Accurate differential bubble pressure method

For R&D, convenient and reliable quality control and process monitoring

3 measurement modes: AUTO, SINGLE & ONLINE

Continuous monitoring is possible through a simple all-in-one interface

Simple operation and powerful functions

Bubble life of 15 milliseconds to 20 seconds covers almost all surface tension applications

price advantage

Fully meet customers' daily use

Easily obtain dynamic surface tension curves using software

use

Used in product research and development of inkjet ink, coating ink, additives, cleaning agents, activators, plating solutions, daily chemical products, alcohol, and petroleum industries, and control of cleaning effects of precision electronic workpieces. By testing the surface tension of the liquid, we can determine the concentration of the surfactant, the migration speed of the surfactant and the wetting and leveling performance of the liquid. like:

Control surface tension and surface activity during production and quality inspection;

In factories and laboratories, monitoring the surface tension of surface-active fluids;

Test the quality of inkjet inks;

Quality control of raw materials including surfactants.

Function

Soft keyboard with various functions displayed;

Directly control the sample temperature before measurement;

Press this key repeatedly to clean or calibrate;

Power switch; press and hold for 2 seconds to turn off;

Instrument status signal. Flashing light indicates measurement is in progress. It will continue to display within one minute after the measurement is completed;

Save measurement results to storage area;

View measurement results from storage area (SINGLE, AUTO, ONLINE).

Pro Line t15

Pro Line t15