Parting tower SITA foam characteristic Tester measurement liquid volume 0-500ml

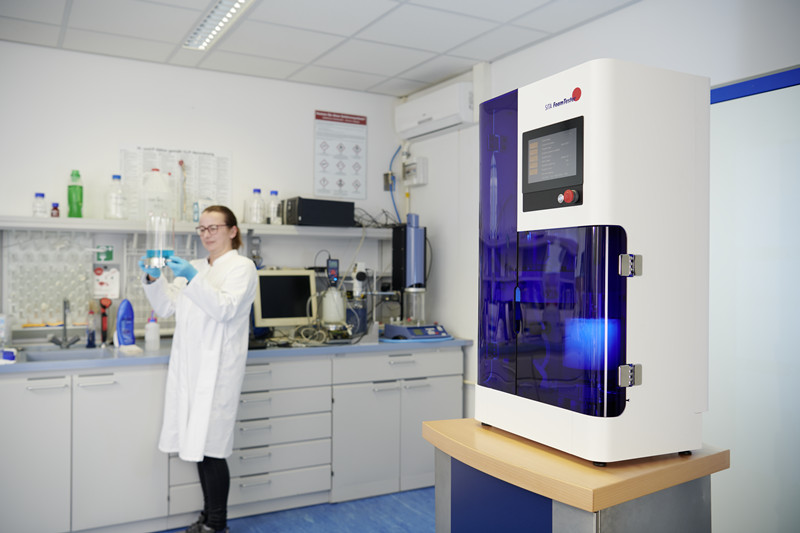

SITA FoamTester foam analyzerSPEC

SITA FoamTester foam analyzerDetails

SITA FoamTester foam analyzerPacking list

- SKU

- NB041855

- Recommended sample Volume

- (200~500) ml

- Available Volume of test tank

- 1500Ml (with foam)

- Appearance size of test tank

- Height 180mm, diameter 110mm

- Sample tank Volume

- 2000ml

- Measurement of sample temperature in containers and Sample chambers

- 0 ~ 60℃

- Stirring speed:

- 0~2000 rpm (bi-directional)

- Adjustable stirring parameters

- Speed, Duration, Direction, Acceleration

- Measured value type:

- Total Volume, foam Volume, liquid Volume

- evaluation parameters

- Maximum foam Volume, foam half-life, flash foam

- Measurement range total Volume

- 0 ~1500 ml

- Measurement range Liquid Volume

- 0 ~ 500 ml

Introduction

Germany's SITA fully automatic foam analyzer FoamTester fully automatically and accurately analyzes the foaming behavior of liquids and monitors the impact of surfactants.

Advantages

Fully automatic analysis of foaming behavior and foam characteristic parameters

Accurately reproduce foam formation

Using innovative optical scanning measurement technology

Measuring foam and liquid volume

Analysis to determine foam structure

Record the entire defoaming and drainage process

Automatic cleaning function

Applications

Optimize products containing surfactants, including the following:

âNew product research and development

âDevelopment and screening of raw materials

âProduct processing and application

âStabilize product quality and process quality

Features

Precise lathering

The foam reproduction method of the SITA automatic foam analyzer has been proven to accurately distinguish various sample formulations and reproducible test sequences; the device is suitable for multiple applications;

The SITA separation tower uses a standard honeycomb rotor for stirring.

Adjustable rotor parameters: stirring times, rotation speed, stirring time, starting speed, stirring direction

The test tank is made of glass, which has less impact on foam formation.

The rotor is integrated into the test tank and can be removed together

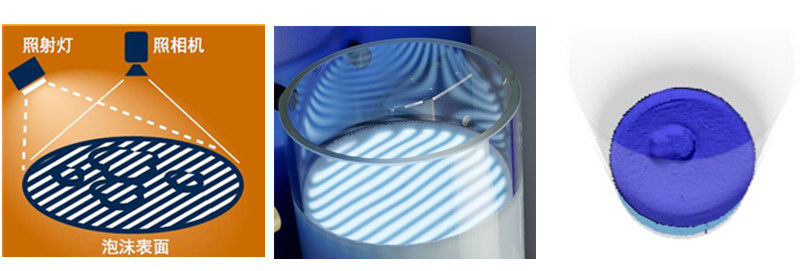

Measuring foam---using non-contact optical measurement technology

Foam surface scanning device: Use structured light measurement method to determine the three-dimensional morphology of the foam surface to determine the total volume of the foam

Foam interface scanning device: Determine foam structure and liquid volume by using a better mobile camera system that illuminates and observes the test tank at an angle higher than the critical angle Î, achieving total internal reflection function

Automatically collect the total amount of liquid and foam through the foam surface scanning device; automatically collect the remaining total amount of liquid and total foam through the foam interface scanning device

All measurements are performed in the same measuring tank and connected to the thermal cycle

Record the foam structure throughout the foam height in the test tank

Analyze foam and understand foaming behavior

Use the SITA-FoamLab operating software in the laboratory for simple and convenient evaluation of measurement data

The test process and results are completely transparently presented to users through intuitive and visual graphics.

During foam formation, analyze slope (foaming speed) and final foam volume (foaming capacity)

Analyze the decay and subsidence process of bubbles

Analyze bubble size and shape in foam structures:

(1) Comprehensive description of foam and foaming behavior

(2) By further determining other parameters, such as: half-life and foam density

(3) By individually evaluating height-related foam structural parameters such as average bubble size or roundness index

(4) By tracking changes in foam structure over time

(5) Different measurement sequences are clearly displayed, allowing for flexible data comparison.

(6) Easily export data and measurement results for archiving and backup

FoamTester

FoamTester