MODERNER SFJ-750D grinding dispersion, mixing machine

SEModerner SFJ-750D Ground dispersing and mixing machineSPEC

Moderner SFJ-750D Ground dispersing and mixing machineDetails

Moderner SFJ-750D Ground dispersing and mixing machinePacking list

- SKU

- NB041923

- Motor power

- 750W

- Speed range

- 0-7500rpm

- Lifting method

- Electric lift

- Lifting stroke

- 210mm

- Power Supply

- 220V 50Hz/60Hz

- Dimension

- 450*420*630mm

- Host Weight

- 28kg

SFJ-400D/750D is an electric lifting small multi-purpose disperser, which adopts electric lifting column instead of traditional manual lifting, and the spindle is driven by a variable frequency motor, which integrates the functions of sanding, dispersing and stirring, and can adapt to different test requirements of the laboratory. This machine adopts stainless steel long-axis inverter motor, the inverter adopts multi-turn speed regulating knob, the display screen directly displays the speed, and the operation button is used to lift the motor, which is convenient to operate and flexible to use.

Equipment details

Use and care

1. Select the appropriate blisk plate and screw it onto the stirring shaft.

2. Loosen the lifting locking handle, adjust the height position of the blisk and the bottom of the mixing drum (positioning ring can be used), and then raise the mixing shaft to feed and place the mixing drum. For the electric lifting type, use the rise and fall buttons on the left side to raise and lower the mixing shaft. In addition, please note that when the power is cut off, the downward force on the mixing shaft will drop to the lowest point. This is normal.

3. Use the Y-shaped gripper to locate and fix the mixing drum.

4. Lower the stirring shaft to the appropriate position, cover the lid of the stirring drum, and tighten the lifting and locking handle.

5. Confirm that the blisk plate is not in contact with the mixing drum, and then you can start stirring. For details of the operation of the inverter, please refer to the "Inverter Panel Operation Instructions" (attached).

6. After stirring, first reduce the stirring speed appropriately and then press the stop button.

7. After each work, please do a good job of cleaning and maintaining the blisk, mixing drum and host equipment in time for subsequent use.

8. This machine is used in the test process of chemical products, and the user should establish appropriate safety and protection measures and determine the rules and regulations in accordance with the relevant safety regulations before use. Safety issues related to contact with chemical raw materials should be established by the user.

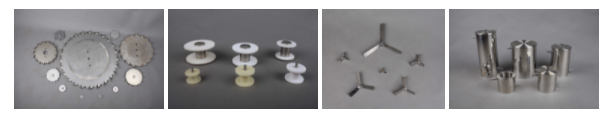

Related Accessories

From left to right: dispersing disc, grinding disc, stirring paddle, stirring, sand grinding cylinder

Ordering Information

| Dispersion disks | φ30-100/120/150/200/300/500mm/customized |

| Sanding discs | φ45/60/80/100/120mm |

| Stirring paddles | φ30-80/100/120/160mm/customized |

| Stirring, sanding abrasive cylinder | 0.25L/0.5L/1.25L/1.8L/2.9L/customized |

SFJ-750D

SFJ-750D