Linshang LS251D Portable Leeb Hardness Tester for metal materials such as iron/copper/steel

SELinShang LS251D Leeb Hardness TesterSPEC

LinShang LS251D Leeb Hardness TesterDetails

LinShang LS251D Leeb Hardness TesterPacking list

- SKU

- NB041946

- Probe Type

- D type impact device

- Hardness system

- HL、HV、HB、HS、HRA、HRB、HRC

- Measuring range

- HLD (170-960); HV (83-976); HB (30-651); HRC (17.6-68.5); HS (26.4-99.5); HRB (13.5-100); HRA (60-85.8)

- resolution

- 1HL

- Measurement Accuracy

- ± 12 HL, ± 6HL typical

- Sexual repeability

- 6HL

- Display

- 240 × 160 dot matrix LCD

- Power Supply

- 2 AA alkalinity dry batteries

- Host size

- 142*72*28 mm

- Probe size

- 148*31*25 mm

- Weight

- 270g

- Operation temperature range

- -10~50 ℃, 0~85% RH (no condensation)

- Storage temperature range

- -10~60 ℃, 0~85% RH (no condensation)

Introduction

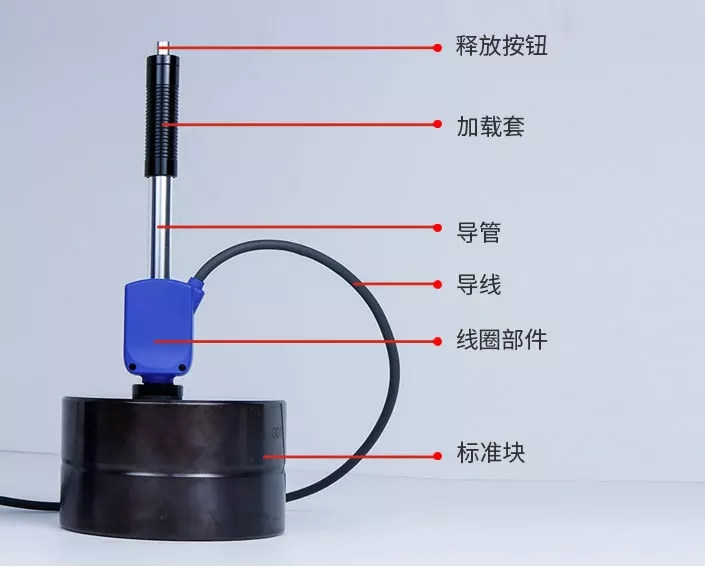

The ability of a material to locally resist the pressing of hard objects into its surface is called hardness, which is an index to measure the softness and hardness of the material. LS251D Leeb Hardness Tester detects hardness based on the principle of Leeb hardness measurement, and can measure the hardness of various metal materials. The instrument adopts excellent digital probe technology, digital signal processing is completed directly on the probe, the probe is not easily disturbed and provides excellent test accuracy. The probe has a built-in direction sensor, which automatically compensates the measurement error of different impact directions. The system has a variety of built-in hardness scales, including Leeb (HL), Vickers (HV), Brinell (HB), Shore (HS), Rockwell (HRA), Rockwell (HRB), Rockwell (HRC) and tensile strength (σb) to avoid cumbersome manual calculations. The practical value of using LS251D Leeb Hardness Tester for hardness testing lies in its unparalleled portability - simple operation, easy to carry, and batch testing can be realized.

Application

LS251D Leeb Hardness Tester is suitable for metal materials such as steel, cast steel, alloy tool steel, stainless steel, gray cast iron, ductile iron, cast aluminum alloy, copper-zinc alloy, copper-tin alloy, pure copper and forged steel. The instrument can be widely used It is used for hardness testing of materials such as machine tool guide rails, automobile chassis, heavy workpieces, mold cavities, bearings, pressure vessels, and installed machinery or assembly parts. It can help manufacturers conduct product quality inspection, reasonable process and product quality analysis.

Standards

GB/T 13794.1 Leeb Hardness Test Part 1: Test Method

GB/T 13794.2 Leeb Hardness Test Part 2: Calibration and Calibration of Hardness Testers

GB/T 13794.4 Leeb Hardness Test Part 4: Hardness Value Conversion Table

JB/T 9378-2001 Leeb Hardness Tester industry standard

JJG 747-1999 Verification Regulations for Leeb Hardness Tester

- 1DL/T 1845-2018《Test method for Leeb hardness of high-alloy steels in power equipment》

- 2GB/T 13313-2008《Methods of shore and leeb hardness testing for rolls》

- 3GB/T 17394.1-2014《Metallic materials―Leeb hardness test―Part 1: Test method》

- 4GB/T 17394.4-2014《Metallic materials―Leeb hardness test―Part 4:Tables of hardness values conversation》

- 5GB/T 17394.3-2022《Metallic materials—Leeb hardness test—Part 3: Calibration of reference test blocks》

- 6GB/T 17394.2-2022《Metallic materials—Leeb hardness test—Part 2: Verification and calibration of hardness testers》

- 7GB/T 17394-1998《Metallic materials--Leeb hardness test》

LS251D

LS251D