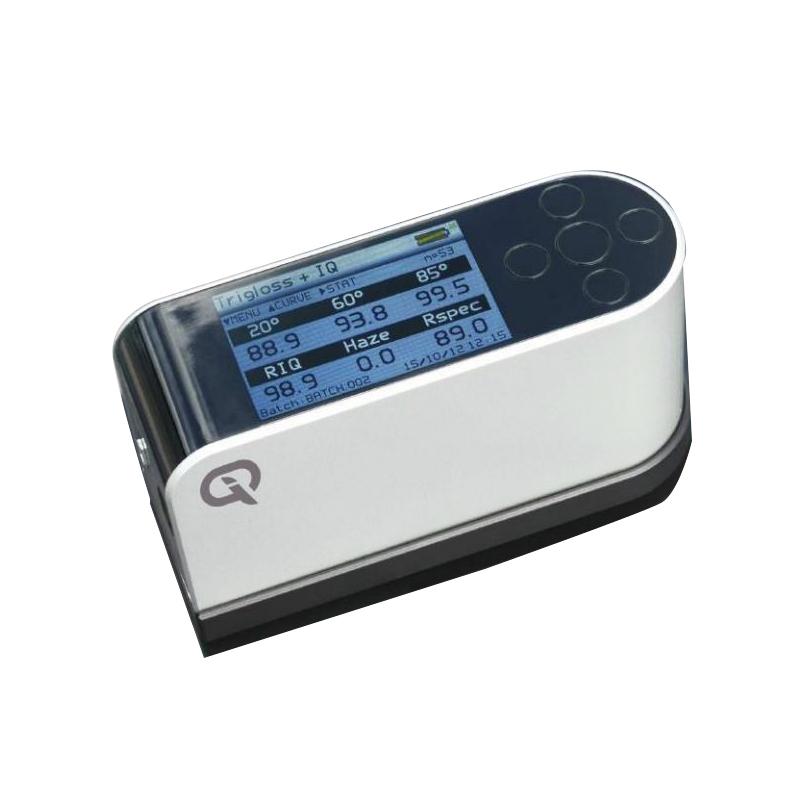

RHOPOINT IQ206085 Three angle distinctness of image Glossmeter

RHOPOINT IQ206085 Three angle GlossMeterSPEC

RHOPOINT IQ206085 Three angle GlossMeterDetails

RHOPOINT IQ206085 Three angle GlossMeterPacking list

- SKU

- NB042113

- Measurement angle

- 20°/60°/85°

- Measurement range

- 20°:0-2000GU;60°:0-1000GU;85°:0-199GU

- Repeatability

- ±0.2GU

- Reproducibility

- ±0.5GU

- Measuring Areas

- 20°: 6mm×6.4mm;60°: 6mm×12mm;85°: 4mm×45.9mm

- Standards

- ISO 07668、ISO 2813、ASTM D523、ASTM D2457、DIN 67530、JIS 8741、ASTM E430、ISO 13803、ASTM D5767

- Interface

- Bluetooth, compatible PC and MAC, USB connection, no software installation required

- Data storage

- 999 readings

- Operating language

- Chinese, English, French, German, Spanish, Italian, Japanese, Turkish

- Dimensions

- 65mm×140mm×50mm

- Weight

- 790g

- Operating temperature

- 15~40℃ (60~104°F)

- Operating humidity

- Up to 85% without condensation

- Peak specular reflection

- 20°±0.09905°

- Measurement range of peak reflectance

- 0-2000GU

- Fog shadow range

- Near mirror reflection measurement in the range of 17-19 °, 21-23 °

- Fog Shadow Unit

- HU and LogHU can be converted to each other

- Shadow resolution

- 0.1HU

- Shadow Repeatability

- ±0.2HU

- Shadow reproducibility

- ±1.5HU

- Measurement range of imagery Mass

- 0-100

- Imagery Mass resolution

- 0.1

- Repeatability of imagery Mass

- ±0.2

- Imagery Mass reproducibility

- ±0.5

- Measurement range of image distinctness

- 0-100

- Distinctness of image resolution

- 0.1

- Repeatability of image distinctness

- ±0.2

- Distinctness of image reproducibility

- ±0.5

- Glossiness Calibration plate

- Traceability: ISO 17205 certified, traceable to BAM

- Glossiness Calibration plate uncertainty

- 0.4GU

- Display

- Full color screen, adjustable luminance, 6 touch buttons

- Appearance structure

- All aluminium construction - housing, Optical inspection parts, calibrated base with positioning detection

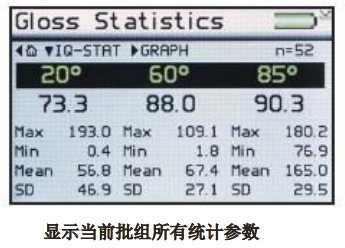

- statistical analysis

- Maximum/MIN Minimum, average, standard deviation, all Measurement parameters

- graphical analysis

- Built-in trend analysis, Gloss, and IQ

- Power life

- Rechargeable lithium battery, more than 17 hours of operation, more than 20,000 readings

- Power Supply

- Built-in battery/USB/power charger

- Charging time

- USB connection power charger: < 4 hours

- Encasement Weight

- 1.75kg

Rhopoint IQ can handle problems traditional gloss meters can't

Image quality is measured with the Rhopoint IQ, a handheld surface optical Detector that describes how light reflects from an object's surface. Traditional gloss meters can only measure the amount of reflected light, but cannot measure the impact of imaging quality on sensitivity.

Surface texture diminishes the quality of surface imaging without affecting gloss values. The gloss values ââmeasured by the traditional gloss meter on the two panels are the same.

Haze is a common phenomenon in painted and polished products that creates a milky appearance on the surface, reducing image clarity. Rhopoint IQ can quickly detect whether .

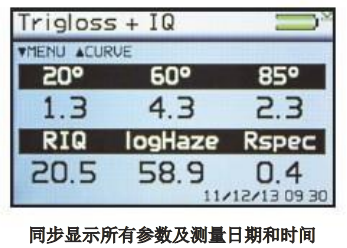

Rhopoint IQ can measure 20/60/85° gloss (GLOSS), peak reflectance (RSPEC), reflection haze (HAZE), imaging quality (RIQ), vividness (DOI), and reflection curve distribution.

Gloss (GLOSS)âMeasures the percentage of the amount of light reflected.

-Geometric analysis: In order to obtain more accurate data, corresponding light paths should be selected for different surfaces: matte: 85°, medium gloss: 60°, high gloss: 20°

Peak reflectivity (RSPEC) - is an indicator of light intensity within a small range of angles from the reflection angle .

-Purpose: Peak reflectance is very sensitive to subtle changes in texture and is used to discern subtle differences in texture on smooth surfaces.

Haze (HAZE) â An optical effect called haze that causes a milky appearance to the microstructure caused by poor pigment dispersion in the paint .

-Phenomena: Haze is a phenomenon that occurs on medium to high gloss surfaces. The micro-textured medium-high gloss surface produces low-intensity scattered light in the direction close to the main reflected light, but most of the incident light is reflected in the mirror, making the surface look high-gloss and imaging quality, but the image has a milky haze . . The lower the haze reading, the better the surface quality.

-Causes: poor dispersion, incompatibility of raw materials, no additives, quality of additives, environmental conditions during drying/drying/curing, polishing marks, fine scratches, aging, oxidation, insufficient cleanliness and surface residues things.

Reflection haze compensationâ The instrument obtains reflection compensation from highly reflective coatings, metallic paints, and special coatings to measure haze on the surfaces of these coatings.

Imaging quality (RIQ) - RIQ is used as an indicator . Compared with DOI, RIQ has higher resolution and is closer to the characteristics observed by the human eye, especially on high-quality surfaces, such as Car surface, etc.

Phenomenon of low image quality: orange peel, brush marks, ripples or other surface textures, causing the reflected image to be distorted.

Imaging quality (RIQ) - RIQ is used as an indicator . Compared with DOI, RIQ has higher resolution and is closer to the characteristics observed by the human eye, especially on high-quality surfaces, such as Car surface, etc.

Phenomenon of low image quality: orange peel, brush marks, ripples or other surface textures, causing the reflected image to be distorted.

- Causes: Process problems, irregular paint leveling, paint viscosity too high or too low, paint sag or flow before curing , pigment size or distribution that does not meet specifications, overspray, incorrect lighting and spraying time, paint gaps compatibility, incorrect baking time or temperature.

Distinctiveness of Image (DOI) - Measures the clarity of the reflection image of the product on the surface being measured.

Features

Measurement

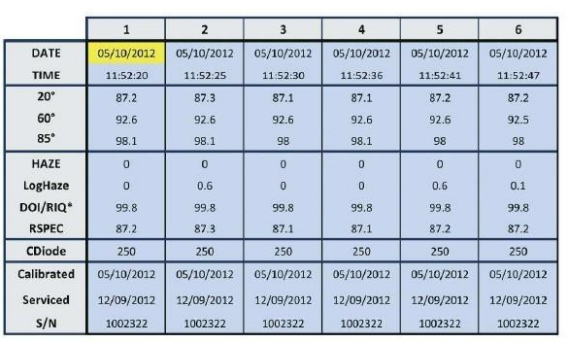

Quickly measure and count all parameters and generate trend analysis graphs.

reflection curve

Different surface textures produce different reflection curves. These curve graphics can be downloaded to the computer via USB data cable or Bluetooth for later data analysis and comparison.

Simplified batch processing

Users can quickly and efficiently customize batch names and batch group sizes.

Transfer data quickly

No software installation required.

When the USB data cable is connected to the computer, the drive position can be quickly identified, thereby promoting rapid data transfer.

Direct data entry via Bluetooth

Measurement data can be instantly transferred to computer/tablet/smartphone and generated directly

Power

20,000+ readings

It can be charged with a USB data cable or power supply, or can be used at the same time.

Application

Paint coating, yacht manufacturing, polished metal, polished stone, smartphones, tablets, laptop displays, wood coating, automobile manufacturing, printing ink, automobile repair, powder coating, automobile coatings, furniture manufacturing, plastic products.

- 1GB/T 13217.2-2024《Test method for gloss of ink》

- 2ISO 《Paper and board - Measurement of specular gloss - Part 3: 20° gloss with a converging beam, TAPPI method (Second Edition)》

- 3GB/T 42789-2023《Test method for gloss of silicon wafer》

- 4GB/T 13448-2019《Test methods for prepainted steel sheet and strip》

- 5GB/T 21867.3-2008《Pigments and extenders - Methods of assessment of dispersion characteristics - Part 3:Assessment from the change in gloss》

IQ206085

IQ206085