Constant heat and humidity cyclic Test Chamber black garlic machine NBC-HW-150 -20 ℃/150L

SE-

CHINA NBC-150L-20 High-precision Constant Temperature and Humidity Chamber Paint Panel -20 ℃/150L$ 2656.00SE

CHINA NBC-150L-20 High-precision Constant Temperature and Humidity Chamber Paint Panel -20 ℃/150L$ 2656.00SE -

CHINA NBC-150L-20 Laboratory high-low temperature heating and Humidity Chamber heating and humidity cycle testing machine -20 ℃/150L$ 2656.00SE

CHINA NBC-150L-20 Laboratory high-low temperature heating and Humidity Chamber heating and humidity cycle testing machine -20 ℃/150L$ 2656.00SE -

KESIONOTS KS-HW150C electronic humidity chamber -20~ 150 ℃/150L$ 4848.00SE

KESIONOTS KS-HW150C electronic humidity chamber -20~ 150 ℃/150L$ 4848.00SE

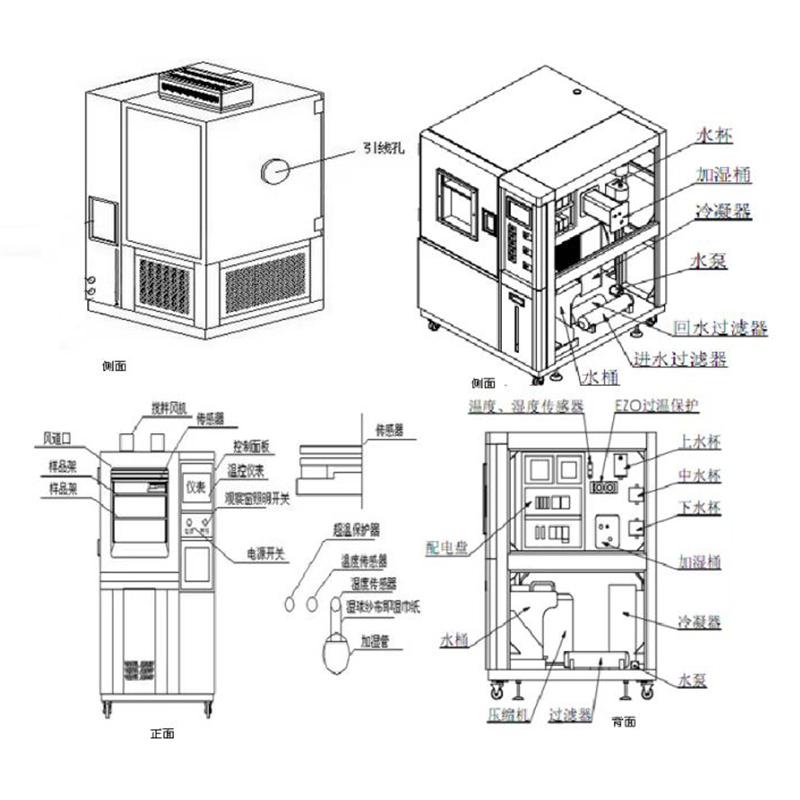

JiangKai NBC-HW-150(-20℃) Humidity ChamberSPEC

JiangKai NBC-HW-150(-20℃) Humidity ChamberDetails

JiangKai NBC-HW-150(-20℃) Humidity ChamberPacking list

- SKU

- NB042190

- Interior Volume

- 150L

- Temperature range

- -20℃~150℃

- Temperature fluctuation

- 0.5℃

- Humidity control range

- 20%~98%R.H.

- Humidity Deviation

- ≤3%

- Interior size

- 500*500*600mm

- Overall Dimensions

- 1000*1120*1500mm

- Temperature deviation

- ≤2℃

- heating time

- From room temperature to 150 ℃ for about 40 minutes (no-load nonlinear)

- Cooling time

- From room temperature to -60 ℃ for about 60 minutes (no-load nonlinear)

- Humidity fluctuation

- 3%R.H.

- Inner box material

- Stainless Steel Plate (SUS #304)

- Enclosure Material

- Stainless steel plate atomized (SUS #304) or cold plate paint (optional)

- Thermal insulation material

- Rigid Polyurethane Foam and Glass Cotton

- Air supply circulation system

- (1) 1 90W motor; (2) Stainless steel extended shaft; (3) Multi-wing fan blade (SIRCCO FAN)

- Box door

- Single door, single window, left open, handle on the right

- Box door window

- 260X340x40mm, 3 vacuum layers

- compressor

- Fully dense compressor imported from France

- refrigerant

- Environmentally friendly refrigerant R404A

- Condenser

- Fin type with cooling motor

- Evaporator

- Fin type multi-stage automatic load Capacity adjustment

- Miscellaneous accessories

- Drying agent, refrigerant flow window, expansion valve

- expansion system

- Capacity Controlled Refrigeration System

Standards

The performance indicators meet the requirements of GB5170, 2, 3, 5, 6-95 "Basic parameter verification methods for environmental test equipment for electrical and electronic products, low temperature, high temperature, constant damp heat, alternating damp heat test equipment"

Basic environmental test procedures for electrical and electronic products Test A: Low temperature test method GB 2423.1-89 (IEC68-2-1)

Basic environmental test procedures for electrical and electronic products Test B: High temperature test method GB 2423.2-89 (IEC68-2-2)

Basic Environmental Test Procedures for Electrical and Electronic Products Test Ca: Constant Damp Heat Test Method GB/T 2423.3-93 (IEC68-2-3)

Basic environmental test procedures for electrical and electronic products Test Da: Alternating damp heat test method GB/T423.4-93 (IEC68-2-30)

Applications

Mainly conduct high-temperature, low-temperature and alternating damp-heat tests on components and materials of other products such as electronics, electrical appliances, household appliances, and automobiles under constant humidity and heat conditions to test their various performance indicators and adaptability.

refrigeration system

A. Compressor: full-sealed compressor imported from France

B. Refrigerant: environmental protection refrigerant R404A

C. Condenser: Fin type with cooling motor

D. Evaporator: finned multi-stage automatic load capacity adjustment

E. Other accessories: desiccant, refrigerant flow window, expansion valve

F. Expansion system: refrigeration system with capacity control

Control System

Imported from Korea with original packaging, full Chinese LCD 7-inch Korean 880 display LCD touch panel, screen conversation input data, temperature and humidity can be programmed at the same time, curve display, set value/displayed value curve. Various alarms can be displayed separately. When a fault occurs, the fault can be displayed on the screen to eliminate the fault and eliminate misoperation. Multiple sets of PID control function, precise monitoring function, and displayed on the screen in the form of data.

1. Controller specifications:

a. Accuracy: temperature ±0.1℃, humidity ±1%RH

b. Resolution: temperature ±0.1, humidity 1%RH

c. Temperature slope: 0.1 ~ 9.9 can be set

d. With upper and lower limit standby and alarm function

e. Temperature and humidity input signal selection PT 100Ω×2 (dry bulb and wet bulb)

f. Temperature and humidity conversion output: 4 ~ 20MA

g. 6 groups of PID control parameter setting, PID automatic calculation, dry and wet bulb automatic correction

2. Screen display function:

a. Touch input, screen direct display option

b. The temperature and humidity setting (SV) and actual (PV) values are directly displayed (in English)

c. It can display the current program number, segment, remaining time and cycle times

d. Running cumulative time function

e. The set value of the temperature and humidity program is displayed as a graphic curve, with the function of real-time display of the program curve execution

f. With a separate program editing screen, directly input temperature, humidity and time

3. Program capacity and control function:

a. Usable program groups: up to 100 groups

b. Usable memory capacity: a total of 5000SEGMENTS

c. Repeatable commands: each command can be up to 9999 times

d. The production of the program adopts a conversational style, with functions such as editing, clearing, etc.

e.SEGMENTS time setting 0~530Hour59Min

f. With power-off program memory, automatically start and continue to execute the program function after power-on

g. When the program is executed, the graph curve can be displayed in real time

h. With date and time adjustment function

i. Button and screen lock (LOCK) function

Equipment main electrical accessories

| Cooling System: | material name | quantity |

| compressor | Taikang (France) | 1 set |

| condenser | Finned cooling fan (Donghua) | 1 set |

| Evaporator | Customization (Zhongli) | 1 set |

| Expansion valve | Danfoss/Honeywell (Denmark) | 2 sets |

| The electromagnetic valve | Danfoss (Denmark) | 2 |

| The electromagnetic valve | Saginomiya (Japan) | 2 |

| pressure controller | Saginomiya (Japan) | 1 |

| oil separator | ALCO (USA) | 1 |

| filter | ALCO (USA) | 1 |

| Refrigerant: R404A | Honeywell (USA) | Appropriate amount |

| Miscellaneous items such as copper pipes | Taishun (Taiwan, CHINA) | 1 item |

| control system: | material name | quantity |

| Temperature and humidity control instrument: | TEMI880 (Korea) color touch screen | 1 set |

| Over-temperature protection instrument : | RKC (Taiwan, CHINA) | 1 |

| Temperature sensor : | Pt100 | 2 |

| Humidity sensor : | Pt100 | 1 |

| contactor | Taian (Taiwan, CHINA) | 2 |

| heat protector | Taian (Taiwan, CHINA) | 1 |

| solid state relay | ANV (Taiwan, CHINA) | 3 |

| Time delay relay | ANV (Taiwan, CHINA) | 2 |

| Intermediate relay | Omron (Taiwan, CHINA) | some |

| Heater | 1 Kw (customized) | 2 pieces |

| Humidification tube | 1Kw (customized) | 1 set |

| Switching power supply (leakage protection) | Lande (Taiwan, CHINA) | 1 set |

| Terminal block | NIM (Japan) | 1 item |

| transformer | custom made | 1 |

| R232 communication interface and software | For monitoring and data logging (optional 1500.00) | 1 set |

| control switch panel | custom made | 1 item |

| Audible alarm | Taian (Taiwan, CHINA) | 1 set |

| heater protection | Taide (Taiwan, CHINA) | 1 set |

| Fluorescent lamp ballast | OSRAM (Germany) | 1 set |

- 1Principle Characteristics and Application of New material Constant Temperature and Humidity Chamber

- 2Principle and Application of Constant Temperature and Humidity Chamber Biochemical Incubator

- 1JJF 1564-2016《Calibration Specification for Temperature and Humidity Standard Chambers》

- 2JJF 1270-2010《Calibration Specification for Temperature/Humidity/Vibration Combined Environmental Testing System》

- 3JJF 1101-2019《Calibration Specification for Environmental Testing Equipment for Temperature and Humidity Parameters》

- 4 2058-2023《Calibration Specification for Environment Parameters of Constant Temperature and Humidity Laboratories》

- 5QX/T 16-2020《Calibration chambers for temverature and humiditv instrument》

- 6JG/T 25-2017《Test method for temperature change resistance of architectural coatings》

- 7 901-2021《Technical specification for the application of fireproof coatings for tunnels》

- 8 10254-2022《Green building materials evaluation fire retardant coating》

- 9GB/T 43489-2023《Sintered neodymium iron boron permanent magnets—Steady state damp heat tests》

- 10GB/T 4893.8-2023《Test of surface coatings of furniture—Part 8: Determination of resistance to abrasion》

NBC-HW-150(-20℃)

NBC-HW-150(-20℃)