CHINA Electronic Seatbox Thermal Shock Test Chamber NBC-LC-80 Temperature control -60 ℃

SEJiangKai NBC-LC-80(-60℃) Hot & Cold Shock climate ChamberSPEC

JiangKai NBC-LC-80(-60℃) Hot & Cold Shock climate ChamberDetails

JiangKai NBC-LC-80(-60℃) Hot & Cold Shock climate ChamberPacking list

- SKU

- NB042215

- Capacity

- 80L

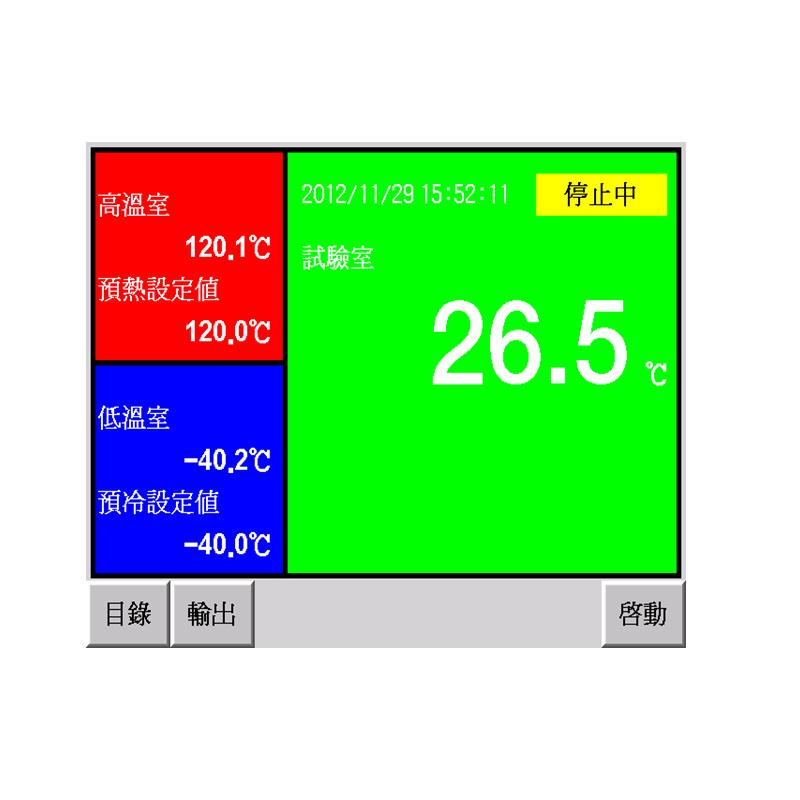

- Temperature and humidity control instrument

- Programmable TEMI8226S imported from Korea, touch screen input, Chinese and English switching.

- Box structure

- This equipment is divided into: high temperature heat storage area, low temperature cold storage area, product test area

- Test area size

- 500mm×400mm×400mm

- Dimensions

- 1600mm×1650mm×1960mm

- Test box temperature shock range

- -60 ℃~ + 150 ℃ (programmable to set arbitrarily)

- Regenerator temperature range

- + 50 ℃~ + 180 ℃ (programmable to set arbitrarily)

- Cold storage box temperature range

- 0 ℃~ -60 ℃ (programmable to set arbitrarily)

- Controller control Accuracy

- ±0.2℃

- temperature shock rate

- Complete within 5min

- Shell material

- stainless steel plate

- Inner box material

- SUS #304 Thickened heat-resistant and cold-resistant stainless steel plate, first-class light panel

- Thermal insulation material

- High Density Glass Cotton and High Strength PU Foam Insulation Material

- Box uniformity

- ±1℃

- Air supply circulation system

- Daily multi-wing centrifugal Circulating Fan, daily motor whole group

- heater

- U-shaped fin type 304 #seamless steel high-speed heating electric heater.

- Refrigeration compressor

- Adopt French Taikang enlarged fully sealed compressor

- Refrigeration accessories

- Table bend center force evaporator, Marr fan, etc

- Cooling method

- Adopt air cooling to dissipate heat

- Sample holder

- Sample Layer Shelf

- Electrical accessories

- Domestic well-known brand electrical components

- Lead Hole

- The left side of the machine Φ50mm

- Wiring method

- The company's electronic control wiring method is implemented in accordance with international electrical standards

- Protection device

- Compressor overheating, overtemperature, overload, high pressure, low pressure, oil pressure, overcurrent, underphase,

- Power

- AC380V 50~60Hz 10~15KW

- Heating method

- High quality nickel-chromium alloy wire electric heater

- The way the air chills down

- Multi-stage diaphragm air heat exchanger

- Box outer wall material

- 1.2mm brushed stainless steel plate

- Environment temperature

- 5~40℃

- Environment humidity

- ≤80%R.H

Overview

This series of high-low temperature thermal shock Test Chambers is mainly used to test the resistance of materials to extremely high or low temperature. This situation is similar to the situation of discontinuously being in high or low temperature. Complete the test in the shortest possible time. Changes or physical damage during thermal shocks are caused by changes in thermal expansion and contraction or changes in other physical values. Only by using the PID system can various products be completely trusted. The effects of thermal shock include electrochemical changes caused by cracking or layer breaking and displacement of the finished product. The full digital automatic control of the PID system will make your operation easy.

The thermal shock testing machine is the testing equipment required by metal, plastic, rubber, electronics and other material industries. It is used to test the material structure or composite material, and it can withstand the extreme high temperature and extremely low temperature in an instant. It can detect the chemical change or physical damage of the sample caused by thermal expansion and contraction in the shortest time. It is divided into two-compartment type and three-compartment type. The difference lies in the different test methods and internal structures. The products meet the standards: GB/T2423.1-2008 test A, GB/T2423.2-2008 test B, GB-T10592-2008, GJB150 .3-198, GJB360A-96 method 107 temperature shock test requirements.

Satisfactory test method: GJB150.5-86 temperature shock test, in line with MIL, IEC, JIS specifications.

Applications

High-low temperature thermal shock Test Chamber is widely used in electronic and electrical components, automation components, communication components, auto parts, metals, chemical materials, plastics and other industries, defense industry, aerospace, military industry, BGA, PCB base plate, electronic chips Changes in the physical properties of IC, semiconductor ceramics and polymer materials, testing the repeated resistance of the materials to high-low temperature and the chemical changes or physical damage of the products in thermal expansion and contraction can confirm the quality of the products, from the precision IC To the components of heavy machinery, it can be used as the basis or reference for product improvement.

Standards

1. GB-2423.1-89 (IEC68-2-1) Test A: Low temperature test method.

2. GB-2423.2-89 (IEC68-2-2) test B: high temperature test method.

3. GJB360.8-87 (MIL-STD-202F) high temperature life test.

4. GBJ150.3 (MIL-STD-810D) high temperature test method.

5. GJB150.4 (MIL-STD-810D) low temperature test method.

6. National military standard GJB150.3-86;

7. National military standard GJB150.4-86;

8. National military standard GJB150.5-86;

Cooling System

1. Refrigeration system and compressor: In order to ensure the cooling rate and minimum temperature requirements of the Test Chamber, this Test Chamber adopts a binary cascade water-cooled refrigeration system composed of a set of 2×6HP imported ifc French Taikang fully enclosed compressors. The cascade refrigeration system includes a high-temperature refrigeration cycle and a low-temperature refrigeration cycle. The connecting container is an evaporative condenser. The evaporative condenser plays the role of energy transfer and transfers the heat energy in the working room through a two-stage refrigeration system to achieve the purpose of cooling. . The design of the refrigeration system uses energy regulation technology, an effective treatment method that can not only ensure the normal operation of the refrigeration unit, but also effectively adjust the energy consumption and cooling capacity of the refrigeration system, so that the operating cost of the refrigeration system can be reduced. And the failure rate drops to a more economical state.

2. Refrigeration Principle: Both the high-low refrigeration cycles adopt the reverse Carrot cycle, which consists of two isothermal processes and two adiabatic processes. The process is as follows: The refrigerant is adiabatically compressed to a higher pressure by the compressor, which consumes work to increase the exhaust temperature, and then the refrigerant conducts heat exchange with the surrounding medium isothermally through the condenser, and transfers the heat to the surrounding medium. Finally, the refrigerant expands adiabatically through the expansion valve to perform work, and the temperature of the refrigerant decreases at this time. Finally, the refrigerant absorbs heat isothermally from the object with higher temperature through the evaporator, reducing the temperature of the object to be cooled. This cycle is repeated so as to achieve the purpose of cooling.

3. Cooling method: air cooling. The air-cooled condenser adopts imported Taiwan, CHINA plate heat exchanger. The evaporative condenser adopts the plate heat exchanger produced by Alfa Laval, which has small volume and high heat transfer coefficient. Thereby greatly improving thermal efficiency and reducing floor space.

4. Refrigerant: DUPONT company R502 (high temperature cycle), R13 (low temperature cycle);

air conditioning system

1. Air conditioning method: forced ventilation internal balance temperature regulation method (BTC). This method means that in the case of continuous operation of the refrigeration system, the control system controls the output of the heater according to the set temperature point through the PID automatic calculation output, and finally achieves a dynamic balance.

2. Air circulation device: Built-in air-conditioning room, circulating air duct and long-axis centrifugal fan, using effective refrigerator and energy regulation system, and effective heat exchange through effective fans to achieve the purpose of temperature change.

3. By improving the air flow of the air, the air flow rate and the heat exchange capacity with the heater and the air surface cooler are improved, thereby greatly improving the temperature uniformity of the Test Chamber.

4. Heating method: high-quality nickel-chromium alloy wire electric heater;

5. Air cooling method: multi-stage diaphragm air heat exchanger;

7. Box structure

1. Cabinet outer wall material: 1.2mm brushed stainless steel plate;

2. The inner wall material of the cabinet: SUS304#1.2mm stainless steel plate.

3. Observation window: a rectangular multi-layer hollow insulating glass observation window (350X250mm) is installed in the high temperature box.

Lighting lamps are installed on the observation window.

4. Insulation material: polyurethane foam is used to connect the outer shell and the low-temperature chamber into a whole through high-temperature and high-pressure foaming.

5. The way of moving the sample chamber: the sample is left still.

control system

1. Temperature measurement: Pt100 platinum resistance

2. Control device: The main controller adopts imported dual-circuit high-precision liquid crystal display touch screen temperature controller.

3. The controller adopts TEMI8226 color screen LCD touch screen imported from South Korea, which can display setting parameters, test curves, running time, heater working status, and PID parameter self-tuning function. The programming of the control program adopts the man-machine dialogue mode, and the automatic operation function of the refrigerator can be realized only by setting the temperature. The control system has a complete detection device that can automatically display detailed faults. Alarm, configuration 485 communication interface and running software.

4. Setting accuracy: Temperature: 0.1°C Time: 1s

5. User program capacity: 30×100 segments.

6. Operation mode: program operation, constant operation.

7. Independent over-temperature protection instrument.

8. The accumulative timer of the working time of the equipment.

technical features

1. It adopts programmable color screen TEMI8226S imported from South Korea, the touch screen input screen display is intuitive and easy to operate, and the data storage function is super long.

2. Reserve the function of switching on and off, end the planning setting, automatically save the data curve after power failure, etc.

3. Real-time experimental curve analysis, equipped with RS232, USB data storage connection

4. After the test, the product under test will automatically return to normal temperature to avoid frost and condensation protection mechanism.

5. Using servo refrigerant flow control technology to effectively save energy by more than 30%

6. The experiment is carried out in a cycle, and it can effectively achieve defrosting once every 5 days, and it only takes 2 hours to defrost, without affecting the impact time

7. The use of pure aluminum fin evaporator can effectively reduce the energy storage time and save energy

8. With two-box and Three-Chamber test functions, in line with test specifications

9. Refrigeration advantages:

10. Low temperature control method of traditional equipment:

ØRefrigeration compressor starts and stops to control the temperature (large temperature fluctuations seriously affect the life of the compressor, a technology that has been eliminated)

ØConstant operation of refrigeration compressor + heating PID control (resulting in offsetting cooling capacity and heating to achieve dynamic temperature balance, wasting a lot of electric energy)

11. The new PWM cold control technology realizes low-temperature energy-saving operation: in low-temperature working state, the heater does not participate in the work, and the refrigerant flow and flow direction of the refrigeration unit are controlled and adjusted through PWM technology, and the refrigeration pipe, cold bypass pipe, and hot bypass pipe are three-way The flow adjustment realizes the automatic constant of the working room temperature. This method can reduce energy consumption by 40% under low temperature conditions.

security measures

1. The studio is overheated;

2. Refrigerator overpressure;

3. The refrigerator is overloaded;

4. Refrigerator oil pressure;

5. The heater is short-circuited or overloaded;

6. The blower motor is overloaded.

7. System leakage protection

8. Ambient temperature: 5-40°C

9. Ambient humidity: ≤80%RH

10. Conditions for guaranteed performance: (Under the following conditions, the minimum attainable temperature is guaranteed to be -65°C)

11. Ambient temperature: ≤30°C (no condensation)

- 1Temperature Impact Test Application of Electronic Components

- 2Stone strike resistance of paint film and its test method

- 3Precision heat & cold shock testing device

- 4Principle, Application and Selection of Main board Thermal Shock Test Chamber

- 5Thermal Shock Test Chamber for printed circuit boards

NBC-LC-80(-60℃)

NBC-LC-80(-60℃)