MODERNER AFA-VIH Miniature Automatic Film Applicator Electric Vacuum

SE-

TM3300 Wire bar & Drawdown Blade Laboratory Film Applicator with Heated Vacuum Table$ 4770.00SE

TM3300 Wire bar & Drawdown Blade Laboratory Film Applicator with Heated Vacuum Table$ 4770.00SE -

HUINUO TM3300pro High-precision Automatic Film Applicator with Drawdown Blade and Rod Applicator, Plus Heated Vacuum Table$ 5710.00SE

HUINUO TM3300pro High-precision Automatic Film Applicator with Drawdown Blade and Rod Applicator, Plus Heated Vacuum Table$ 5710.00SE -

CHINA TBJ-X5-DJ7 removable drawdown blade heating vacuum adsorption Film Coater Coating size 500 * 1000mm$ 10722.00SE

CHINA TBJ-X5-DJ7 removable drawdown blade heating vacuum adsorption Film Coater Coating size 500 * 1000mm$ 10722.00SE -

CHINA Removable metering rod & drawdown blade heating vacuum adsorption laboratory Film Applicator TBJ-X3-DJ11C$ 4457.00SE

CHINA Removable metering rod & drawdown blade heating vacuum adsorption laboratory Film Applicator TBJ-X3-DJ11C$ 4457.00SE -

HuiNuo TM2300 drawdown blade heating Vacuum chuck Film Applicator, small precision Coater$ 4300.00SE

HuiNuo TM2300 drawdown blade heating Vacuum chuck Film Applicator, small precision Coater$ 4300.00SE

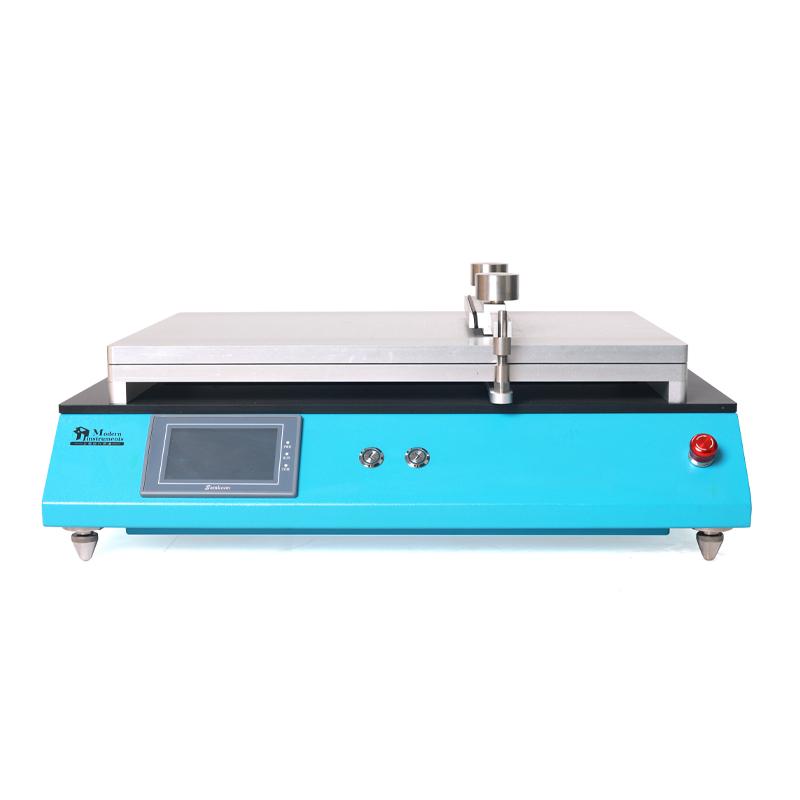

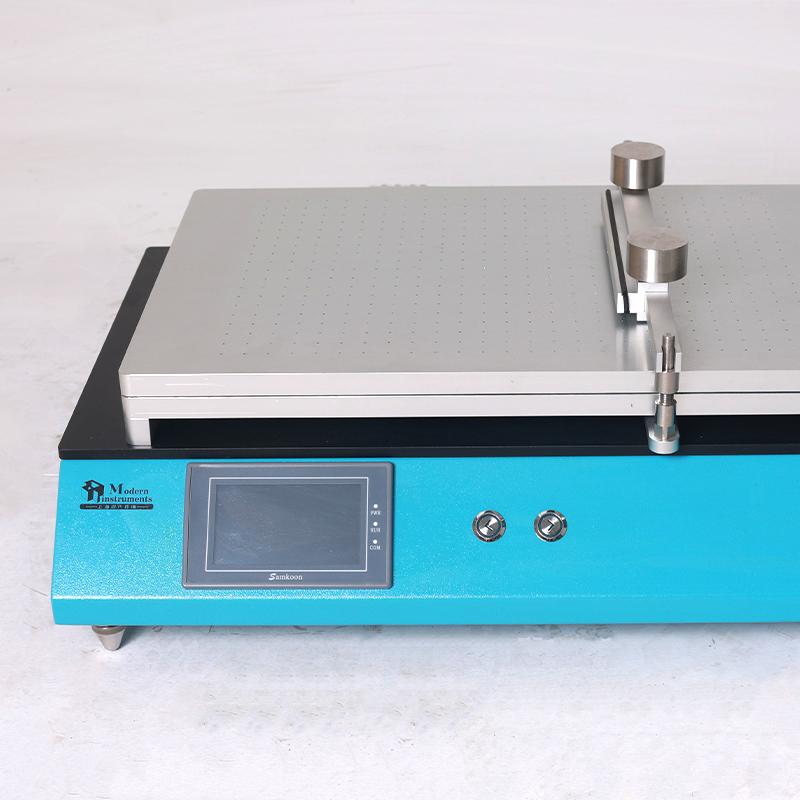

Moderner AFA-VIH Automatic Film ApplicatorSPEC

Moderner AFA-VIH Automatic Film ApplicatorDetails

Moderner AFA-VIH Automatic Film ApplicatorPacking list

- SKU

- NB042241

- Application mode

- Wire rod/scraper

- Application

- 530×350mm

- Vacuum hole distribution

- 400×288mm

- Putter traverse speed

- 2-200mm/s

- Application Itinerary

- 25~400mm

- Vacuumpump configuration

- external

- Heating temperature range

- RT+~100°C

- Key control method

- Knob control

- Host Power

- 220V 50/60Hz

- Overall Dimensions

- 620×450×230mm

- Application material

- Aluminum material

product description

AFA type automatic film coating machine adopts electric push rod to realize the coating movement of Wet Film Applicator or wire bar, which can effectively avoid the instability of manual coating. This machine adopts single-chip microcomputer control technology; the touch screen displays, selects the speed and displacement of the left and right lines, and displays the actual moving distance of the coating in real time during operation; the coating rack can be returned by electric or manual; the operation interface is simple and clear, which is very convenient for the operator to use ; For ease of use, left and right start/stop mechanical buttons and emergency stop mechanical buttons are also added.

AFA-V type has two optional configurations, detachable "vacuum coating table" and "fixture coating table", for customers to choose when ordering. AFA-VI type is "vacuum coating table" configuration. AFA-VH type and AFA-VIH type are "electric heating vacuum coating table" configuration.

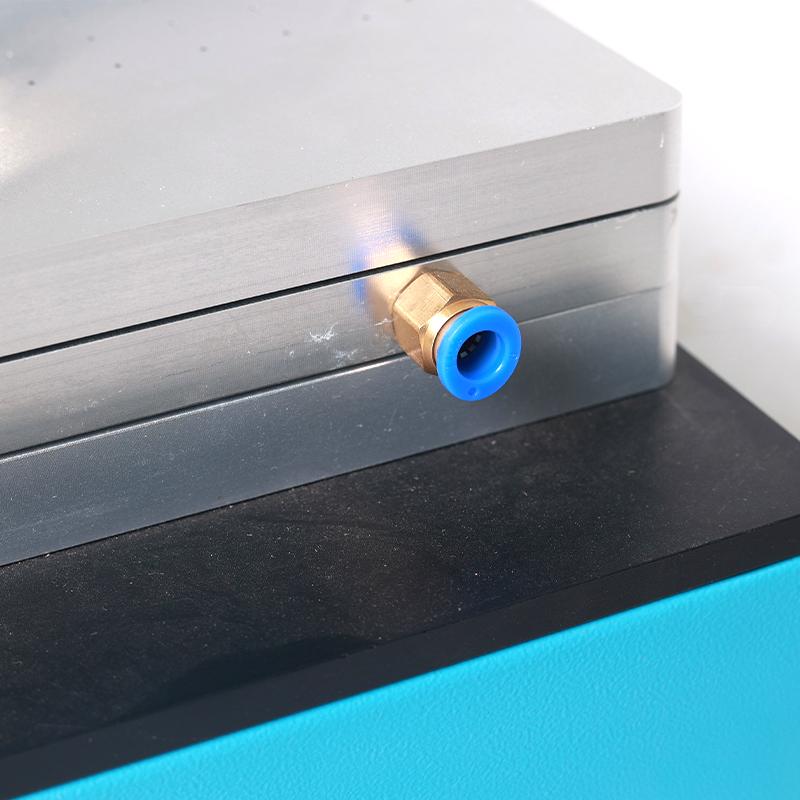

The vacuum coating table uses an external Vacuum Pump (optional). The vacuum coating table panel is positioned by positioning pins, which can be easily removed for cleaning.

The electric heating vacuum coating table uses an external Vacuum Pump (need to be selected separately), and the heating adopts a built-in integrated temperature control.

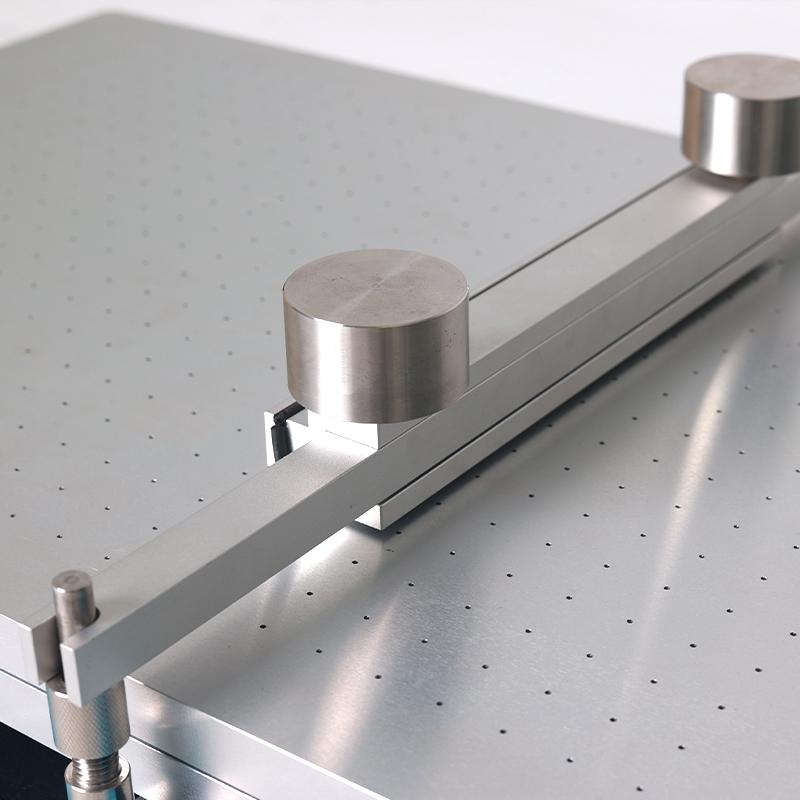

The coating push rod of this machine has been improved, it can be used for Wet Film Applicator, and it can also be used for wire rods of various specifications after installing wire rod push frame, and there is no limit to the length of wire rods. The wire rod push frame has an additional counterweight to meet the pressure requirements during wire rod coating.

NOTE: Wet film prep and wire rods are sold separately.

- 1Kinetic control of silicon carbon cathode Spreader drying: key technology to solve crazing and powder drop

- 2Application of laboratory coater in LED fluorescent film Spreader

- 3Solving the fuel cell electrolysis membrane prepative challenge: Core Functions and Selection Considerations for Multifunctional Laboratory Film Applicators

- 4Experimental Study on High Viscosity Ultraviolet Resin Coating on Glass Substrate by Small Coater

AFA-VIH

AFA-VIH