ASR-9011 Battery Heavy Impact Tester

AISRY ASR-9011 Battery heavy impact testing machineSPEC

AISRY ASR-9011 Battery heavy impact testing machineDetails

AISRY ASR-9011 Battery heavy impact testing machinePacking list

- SKU

- NB042268

- Nominal Mass

- 9.1kg±0.46kg10kg

- Maximum stroke

- 1000mm±25mm

- Impact height

- 610mm±25mm或1000mm

- precision

- ±0.1

- resolution

- 1/100

- Horizontal bar diameter

- 15.8mm

- Box size

- ≈85(D)×80(W)×180(H)cm

- Power

- 1∮,AC220V,3A,51HZ

use

The battery weight impact testing machine is mainly suitable for simulating the deformation and possible explosion of various batteries when they are impacted by heavy objects.

principle

The test sample (battery) should be placed on the flat surface of the pressure plate, and a straight steel rod with a diameter of 15.8mm (5/8 inches) should be placed across the center of the sample. Use a 9.1kg or 10kg±0.46kg (20±1 lb) weight to drop onto the sample from a height of 610±25mm or 1000±25mm (adjustable according to different standards).

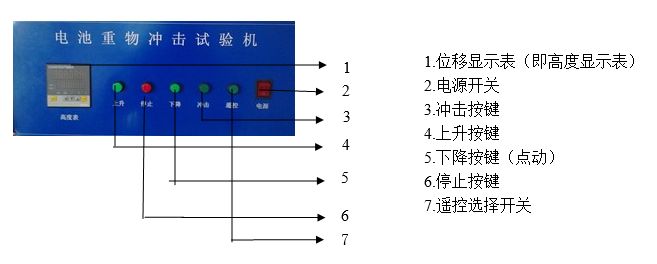

control Panel

According to the standard

This instrument can meet the requirements of GB/T18287-2000, UL1642, QC/T743-2006 and other test methods, and other test methods.

Instrument Installation and Setup

Operating environment requirements: room temperature within the range of 10°C-40°C; ambient humidity within 30%-80%

Others: The machine must be installed and positioned on a level platform with a certain strength.

Steps

First confirm that the power supply Voltage is 220V, connect the power supply, turn on the power switch, and the fan will start randomly;

Before opening the box door, set the required impact height according to the "Displacement Table Setting Instructions", and then press the "Up" button, the falling ball weight will automatically rise to the set test height, and then automatically stop rising.

Before opening the box door, put down the drop hammer (please strictly follow this step to prevent safety accidents), place the sample to be tested at about the center of the pressure plate, and then place the cross bar at the center of the sample to clamp Tighten the battery, close the door, and rise to the set test height.

Press the "Impact" button, and the falling ball weight will fall freely to complete a test.

Precautions

The test sample should be a non-deformed sample or a sample with the casing package intact, so as not to affect the test Conclusion.

Before opening the box door, put down the drop hammer (please strictly follow this step to prevent safety accidents), place the sample to be tested at about the center of the pressure plate, and then place the cross bar at the center of the sample to clamp Tighten the battery, close the door, and rise to the set test height.

When changing the test height, you only need to set it directly on the displacement display table again.

When the test is in progress, please do not open the door to avoid accidents.

Remark

Cylindrical or prismatic cells shall be impacted with their longitudinal axis parallel to the plane and perpendicular to the longitudinal bearing of a 15.8 mm (5/8 inch) diameter curved surface at the center of the recumbent specimen. The prismatic cell is also subjected to a rotation of 90° about its longitudinal axis in order to withstand the impact test on both its broad and narrow sides. Each sample cell only needs to withstand one impact. Different samples are used for each test.

maintenance program

Cleaning: Wipe the instrument with a cotton cloth before and after each test to keep the instrument neat and clean.

Anti-rust: Open the top cover, check whether the relative moving parts of the instrument are operating normally, and add lubricating oil.

Weight maintenance: before each test, wipe it clean with a cotton cloth, after the test, wipe it clean with a cotton cloth and apply anti-rust oil (the weight is a vulnerable part, and anti-rust maintenance measures are very important)

For daily maintenance, please pay attention to the following points:

To keep the testing machine clean;

Do not disassemble and assemble electrical appliances while live, otherwise electronic components may be easily damaged;

The casing of the testing machine should be reliably grounded;

Intermittent operation should be avoided during the test, otherwise it will affect the service life of the equipment; try to operate in place at one time and reduce the number of inching;

Lubricate according to the specified lubrication parts and lubrication methods before starting the machine;

Disassembly and assembly shall be carried out by professionals who understand the structure of the testing machine;

All valves on the testing machine should not be opened to prevent dust from entering the interior and affecting the sensitivity of the measuring mechanism;

When the testing machine is out of service for a long time, it should be coated with anti-rust oil on the working surface and stored in a dry place;

All parts of the equipment should be wiped clean frequently, and more attention should be paid to wiping during the rainy season. When not in use, use a dust cover to prevent dust from intruding.

ASR-9011

ASR-9011