ASR-9016 Battery Needle Extrusion Tester

AISRY ASR-9016 Battery Needle Extrusion Testing MachineSPEC

AISRY ASR-9016 Battery Needle Extrusion Testing MachineDetails

AISRY ASR-9016 Battery Needle Extrusion Testing MachinePacking list

- SKU

- NB042269

Applications

This machine is suitable for all kinds of battery acupuncture tests to simulate the situation where the battery is pierced by an external conductor and destroys the internal structure of the battery when dealing with household waste.

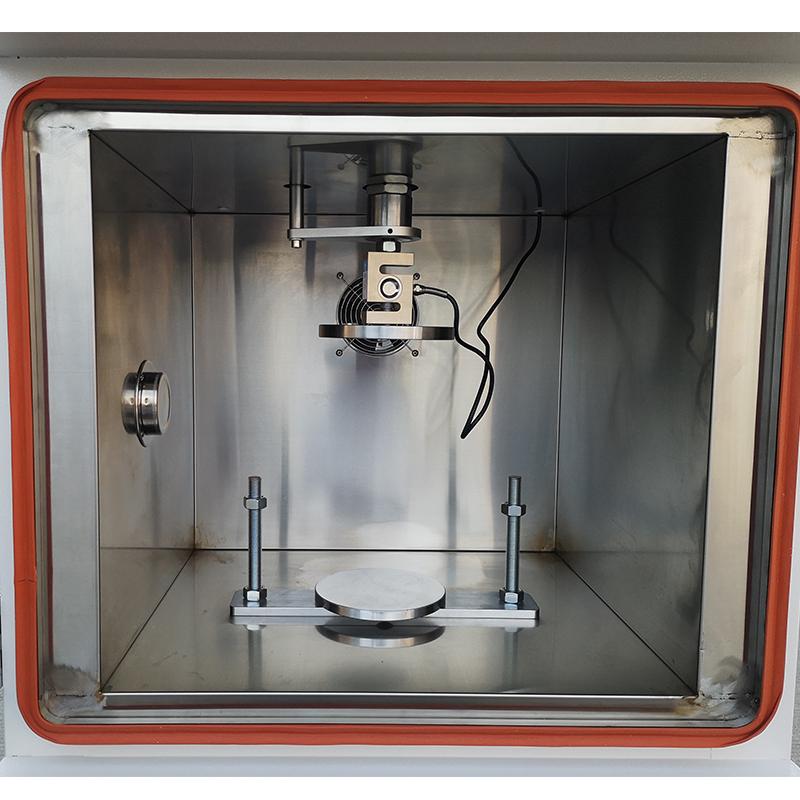

Product principle

The test should be carried out at an ambient temperature of 20°C ± 5°C. The battery is placed flat and clamped on the fixture, and a non-corrosive stainless steel needle with a diameter of ф2~ф8mm is used to pierce the battery at a speed of 10mm/s~40mm/s. The center position of the surface.

According to the standard

This instrument can meet the requirements of GB/T2900.11-1988 GB18287-2013 and other test methods.

Instrument installation

Operating environment requirements: room temperature within the range of 10°C-40°C; ambient humidity within 30%-80%

Operating power requirements: machine power supply is 220V power supply

Others: The machine must be installed and positioned on a level platform with a certain strength.

Steps

Confirm the power supply Voltage of the whole machine;

Open the door of the safety box and place the battery horizontally between the two battery clamps (approximately in the center).

Turn on the power (the fan in the safety box starts), press the reset button to reset, press "Peak", the corresponding "PEAK" indicator light is on

Place the sample on the test bench of the battery acupuncture Tester so that the battery is clamped by the jig,

Set the acupuncture time. After about 3 seconds, the air cylinder will move down and the acupuncture test will be performed automatically. After the preset time is reached, the air cylinder will automatically rise and the steel needle will return to its position; after about 3 seconds, the clamp will automatically release and the battery will be taken out to complete a test.

Note: The magnetic sensitive switch plays the role of adjusting the working stroke.

Precautions

The test sample should be a non-deformed sample or a sample with a well-packaged shell so as not to affect the test Conclusion

Operators need to undergo pre-job training, please strictly follow the test steps during operation

Do not open the door during the test to avoid accidents

5 minutes after the test is completed, remove the tested sample to avoid accidents

maintenance program

To keep the testing machine clean;

Do not disassemble and assemble electrical appliances while live, otherwise electronic components may be easily damaged;

The casing of the testing machine should be reliably grounded;

Intermittent operation should be avoided during the test, otherwise it will affect the service life of the equipment; try to operate it in place at one time and reduce the number of inching.

Lubricate according to the specified lubrication parts and lubrication methods before starting the machine;

Disassembly and assembly shall be carried out by professionals who understand the structure of the testing machine;

All valves on the testing machine should not be opened to prevent dust from entering the interior and affecting the sensitivity of the measuring mechanism;

When the testing machine is out of service for a long time, it should be coated with anti-rust oil on the working surface and stored in a dry place;

All parts of the equipment should be wiped clean frequently, and more attention should be paid to wiping during the rainy season. When not in use, use a dust cover to prevent dust from intruding.

ASR-9016

ASR-9016