CHINA Small hot-melt adhesive Continuous Film Applicator NBC-6025 Continuous Coater

SE

Factory NBC-6025 Small hot-melt adhesive Film ApplicatorSPEC

Factory NBC-6025 Small hot-melt adhesive Film ApplicatorDetails

Factory NBC-6025 Small hot-melt adhesive Film ApplicatorPacking list

- SKU

- NB042280

- Coating method

- Continuous scraping

- Coating size

- Max.300mm

- Spreader thickness range

- 0.01mm~2mm

- Minimum gluing thickness

- 0.01mm

- Coating speed

- 2~ 4.5m/min forward and reverse stepless speed change, recommended Spreader speed: 4.5m/min

- Heating Temperature range

- RT+~200℃

- Reel diameter

- 3 inches.

- Machine Power

- 1050W

- Host Power

- AC220V (single phase) 50Hz

- Machine size

- 1280*600*660mm

- Machine Weight

- About 120kg

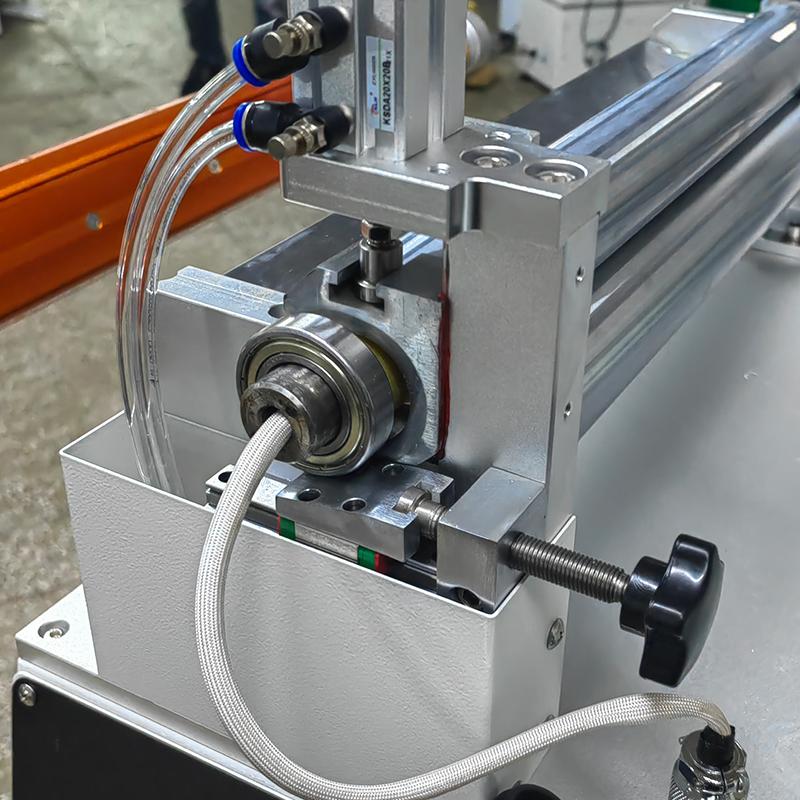

The continuous hot melt adhesive coating and laminating experimental machine is a high-precision modular coating station assembly that can be used for continuous coating and proofing in the laboratory or small batch production. It can directly apply hot melt pressure-sensitive adhesive on the heat-resistant substrate, or you can first apply the adhesive on the release paper, and then transfer the adhesive film to the surface of different materials, such as paper, plastic, and models. Metal film, etc.

Characteristics

The whole machine is assembled and assembled with a high-precision modular coating station structure.

Use a dial indicator as the dividing head to precisely fine-tune the coating gap between the upper and lower rubber wheels to control the coating thickness . The minimum glue thickness is 0.01mm. After the thickness is set, the rubber wheel can be locked directly to prevent the gap from changing.

The maximum coating width is 300mm (effective coating width 280mm). The coating width is adjusted by two Teflon baffles in the glue tank. It can be coated and glued to any length and can be automatically rolled up.

Continuously variable forward and reverse speed, recommended coating speed: 4.5m/min (speed 2-4.5m /min adjustable) The unwinding reel can adjust the knob to change the tension of the unwinding reel. The take-up reel can be adjusted with mechanical tension control.

The heating rod, upper rubber wheel and rubber tank can be quickly disassembled and separated from the machine body to remove residual glue.

- 1Working Principle and Operation Method of Small Hot-melt adhesive Continuous Film Applicator

- 2Comparison of Different Spreader Methods of Small Coating coater

- 3Mechanism, Function and Selection Considerations of Anti-hair Flower Agent

- 4Water-based Pressure sensitive adhesive coating machine selection technical guide

- 5Comparison and Difference Between Offset Press and Film Applicator

- 6Resin hot-melt adhesive coater technology depth analysis

- 7Spraying defects and treatment methods

- 8Analysis and application of self-adhesive laboratory coater technology

- 9In-depth interpretation of laboratory hot-melt adhesive machine: technical characteristics and comparison with production equipment

- 10The working principle and application of inks heating coater

NBC-6025

NBC-6025