Aipei AP-HX-1000F programmable high and low temperature alternating damping heat test chamber 1000L/-70 ℃

Apkjgroup AP-HX-1000F Programmable humidity ChamberSPEC

Apkjgroup AP-HX-1000F Programmable humidity ChamberDetails

Apkjgroup AP-HX-1000F Programmable humidity ChamberPacking list

- SKU

- NB042357

- Interior Volume

- 1000L

- Temperature range

- -70~150 ℃ (air-cooled)

- Temperature Resolution

- 0.01℃

- Temperature Fluctuation

- ±0.5℃

- Temperature Uniformity

- ±2.0℃

- Humidity control range

- 20~98%R.H

- Humidity Deviation

- ±2%R.H

- Ambient Temperature

- 5~30℃

- Interior size

- 1000*1000*1000mm

- Dimensions

- 1280 * 2250 * 1900Mm (W * H * D) The actual size shall prevail

- Weight

- About 700kg

- Cooling rate

- RT~ 0 ℃/about 25min (no load) about 1 ℃/min

- Heating rate

- RT~ + 150 ℃/about 40min (no load) about 3 ℃/min

- Humidity Accuracy

- 0.1%R.H

- Humidity Uniformity

- ≤±3%R.H

- Chamber material

- SUS304 stainless steel

- Enclosure Material

- Cold rolled steel plate

- Outer box light source

- High luminance lamp

- Viewing Window

- Observe the use of the sample

- Window sweat-proof design

- Electric heater device to prevent water condensation (40W)

- test hole

- Can be used for external test power cord and signal (diameter 50mm)

- Insulation material

- Rigid polyurethane foam

- In-box tray rack

- Movable adjustable grid plate frame and two stainless steel strip grid plates (5.0cm per grid of the grid frame)

- Box door

- Adopt double-channel heat insulation and air tightness to effectively isolate external temperature leakage

- Operating Mode

- The 0 ℃ to -40 ℃ model adopts one-stage compression, and the -40 ℃ to -70 ℃ model adopts binary cascade refrigeration.

- Refrigeration system

- Original imported French Taikang fully enclosed low noise rotor compressor or Japan Hitachi effective fully enclosed compressor

- refrigerant

- R404a/R23 (ozone depletion index is 0, R23 is used for cascade refrigeration systems)

- Condenser

- Air-cooled: finned tube heat exchanger. water-cooled: shell and tube heat exchanger

- Evaporator

- Finned tube heat exchanger (also serves as a dehumidifier)

- Condenser

- Stainless steel brazed plate heat exchanger (used in cascade refrigeration systems)

- Throttle device

- Expansion valve + capillary tubing

- Maximum current consumption

- Current: 14A; Power: 3.0KW [Voltage range: no more than +/- 10%]

- Protection compressor

- Compressor high Voltage protection: Danfoss high Voltage protection switch; compressor overcurrent, overheating protection: Schneider thermal relay

- Protective heating

- Chint fuse: 2 groups

- Protection instrument

- Instrument protocol Temperature upper limit Overtemperature protection

- Chamber material

- SUS304 stainless steel

- Enclosure Material

- Library board electrostatic high temperature baking paint

- Test Shelf

- SUS304 box rack with machine pulley, the specific quantity is agreed on site

- Over temperature protector

- Test area over-temperature protection, real-time display test area temperature, temperature over the upper limit sound and light alarm and cut off the instrument Power .

- Relative Humidity

- ≤85%

- Ambient Pressure

- 86kPa~ 106kPa normal atmospheric pressure

Applications

The programmable high-low Temperature Test Chamber mainly provides complex high-low temperature alternating test environments and test conditions for testing in all aspects of electronic parts, industrial materials, and finished product R&D, production, and inspection. It is suitable for electronic and electrical communications, chemical industry, hardware, rubber, and toys. , scientific research and other industries.

control instrument

7-inch ultra-large touch AP-900 intelligent programmable temperature and humidity controller: 120 sets of programs, each set of programs has 100 segments. You can set all programs to cycle, part to cycle, program connection, program end action, and standby action. It can connect USB flash drive to record test data in real time, export test historical data, and import pictures. Standard RS232 communication interface, maximum communication speed 115200bps, (optional RS485, maximum communication distance 1.2km, can connect up to 99 units).

Test box features

â The programmable constant temperature and Humidity Test Chamber is mainly composed of a control panel, a switchboard, an insulation partition, a blower, a heater, a humidifier, and a freezer. The main specifications can be divided into 6 standard sizes and 10 specifications for different conditions.

â The controller can be connected to the computer via the LAN interface. Users can design programs on the computer screen, collect test data and records, call program execution, remotely control the machine on and off, and other functions.

â Use the multi-wing blower to provide powerful air circulation to avoid any dead spots and make the indoor temperature and humidity evenly distributed.

â Complete safety protection device. If an abnormal situation occurs, the controller screen will automatically display the fault status, cut off the power switch, and provide troubleshooting methods.

fulfill the standard

GB/T10589-2008 Low Temperature Test Chamber technical conditions

GB/T10586-2006 Technical Conditions of Humid Heat Test Chamber

GB/T10592-2008 High-low Temperature Test Chamber technical conditions

GB/T2423.1-2008 Low temperature test Aa, Ab

GB/TT2423.2-2008 Test B: High Temperature Test Method

GB/T2423.3-2006 (IEC68-2-3) Constant damp heat test Ca

MIL-STD810D method 502.2

GB/T2423.4-2008 (MIL-STD810) Method 507.2 Procedure 3

GJB150.9-1986 Environmental test method for military equipment-damp heat test

GB2423.34-2012, MIL-STD883C method 1004.2 Temperature and humidity combined cycle test

Specimen limits

This testing equipment prohibits the testing of flammable, explosive, and volatile substance samples, the testing of stored corrosive substance samples, the testing of biological samples, or the testing or storage of strong electromagnetic emission source samples.

Installation site

1. There is no strong vibration around the equipment; the ground is flat and well ventilated.

2. There is no strong electromagnetic field influence around the equipment; there is no flammable, explosive, corrosive substances and dust.

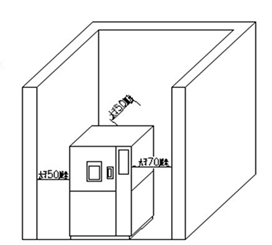

3. Leave appropriate space for use and maintenance around the equipment, as shown in the figure below:

Power supply conditions

â»The user is required to configure an air or power switch of corresponding capacity at the installation site, and this switch needs to be an independent AC220V power supply for this equipment. Requirements:

1. Single-phase two-wire + protective ground wire;

2. Voltage range: AC (220±10) V

3. Allowable frequency fluctuation range: (50±0.5) Hz

4. The grounding resistance of the protective ground wire is less than 4Ω

Note: This plan does not include the installation of external environmental items such as ventilation ducts, power supplies (cables, leakage switches), air sources (Air Compressors), water sources (bottled water or water pipes) and other equipment

Main parts list

Cooling System

1. Compressor unit (1)

Original imported "French Taikang" high-efficiency fully enclosed compressor,

The efficient, low-slip large-volume F-class insulated motor of this brand of compressor ensures the high cooling capacity, low power consumption and operational safety of Taikang fully enclosed compressors. Taikang compressors have long-term use in different regions and different climatic conditions in my country. They have been proven for a long time and have stable and reliable performance. The optimal balance design of Taikang compressor makes the compressor have small vibration, low noise and more stable operation.

2. Compressor unit (2)

Original imported "Japanese Hitachi" high-efficiency fully enclosed compressor,

This brand of compressor has lower vibration and noise, a fixed crankshaft structure and a large enough exhaust buffer structure, making vibration and noise smaller. It has high cooling capacity, low power consumption and safe operation.

3. Oil content

"American Henry" separates refrigerant and oil, allowing the oil to return to the compressor for recycling and energy saving.

Features

1. Built-in oil filter

2. The outer coating is anti-corrosion epoxy spray paint

3. Oil separation rate 99%

4. Evaporator

"Taiwan, CHINA Zhongli" fin evaporator and copper tube are mechanically expanded to ensure close contact and achieve better heat exchange effect. The evaporator copper tube is made of high-purity seamless copper tube, which has a long life and is not easy to crack and corrode.

5. Filter

Advantages and features of "Denmark Danfoss" filters:

1) Bidirectional flow filter dryer

2 ) Ensure rapid and effective adsorption of moisture as well as inorganic and organic acids

3 ) The filter housing has UL certification, PS/MWP up to 46 bar/667 psig

4 ) Provided with solder (copper plated steel) and bell mouth connections

5 ) Change of flow direction without dust release

6. Capillary tube

"Taiwan, CHINA Xiongde" copper pipe: plays the role of circulation, throttling, and pressure reduction in the refrigeration system.

The expansion valve "Denfoss" has a wide flow adjustment range and can operate according to various preset adjustment rules to obtain good superheat adjustment quality, which greatly improves the startup characteristics and variable load dynamic characteristics of the refrigeration device. High efficiency, stable operation, low energy consumption, and good temperature control accuracy

7. Refrigerant

Features of "American DuPont" environmentally friendly refrigerant R-404/R23:

1 ) DuPont refrigerant and lubricating oil have good mutual solubility.

2 ) DuPont refrigerant is safe. The working fluid should be non-toxic, non-irritating, non-flammable and non-explosive.

3 ) DuPont refrigerant has good electrical insulation.

4 ) DuPont refrigerant is economical, requiring the working fluid to be cheap and easy to obtain.

5 ) DuPont refrigerant has excellent thermophysical properties. The specific requirements are: higher heat transfer coefficient, lower viscosity and smaller density.

8. Liquid storage bottle

Storage of refrigeration fluid, separation of liquid and vapor, preventing liquid shock in the compressor, filtering impurities, reducing noise and oil return, etc. The liquid receiver is installed after the condenser in the system to store high-pressure liquid to ensure the need for adjustment of the refrigerant liquid storage capacity of the refrigeration system when the cooling load changes. It is also helpful to reduce the number of refrigerants replenished to the system during regular

9. Heat exchanger

Advantages of "Japan Eastern Union" products

1 ) Compact structure and easy to install

2 ) Light weight, only equivalent to 20~30% of shell and tube heat exchanger

3 ) Durable and able to withstand high temperature and pressure.

10. Condenser

Features of "Taiwan, CHINA Keweili" air-cooled condenser:

1 ) The product has a reasonable structure. The panel and side panels adopt a stepped structure, which is stronger and reduces the vibration of the fan and the noise it generates. The water tray and both sides are easily removable.

2 ) The shell is phosphated and sprayed on the surface, which has the characteristics of corrosion resistance, smooth and beautiful surface, and long service life.

3 ) The copper pipe adopts fully automatic processing and forming technology to ensure that the inside of the pipe is dry and clean.

4 ) The coil has passed the 2.6MPa air tightness test to ensure the air tightness requirements of the product;

5 ) The copper tubes and fins are expanded by a hydraulic machine. The fins and copper tubes are tight, uniform, stable, and have high heat transfer performance.

11. Automatic Voltage control (Danfoss)

"Danfoss" pressure switch is used to control the compressor overload braking protection device.

Features

1 ) It adopts British pipe thread quick connector or copper pipe welding installation structure, which is flexible in installation and easy to use, and does not require special installation and fixation.

2 ) The sealed stainless steel sensor is safe and reliable.

Solenoid valve (Castal)

1 ) The Castro solenoid valve is equipped with an O-ring screw system to ensure waterproofing and simplify the integrated connection of the coil;ãã

2 ) The coil can be connected with a plug-in connector. This connector is equipped with 3 wires, which is extremely convenient.

3 ) The valve can operate normally when there is no pressure difference in the medium.

4 ) The electromagnetic coil is made of insulating and moisture-proof material, which is waterproof and shockproof.

5 ) When the solenoid valve needs to replace the solenoid coil for some reason, there is no need to shut down the system.

Heating system

1. Nickel chromium heater

"Taiwan, CHINA Longxing" nickel-chromium material has high strength, resistance to high temperature, low temperature, humidity and heat, and strong plasticity.

2. Solid state relay (Taiwan, CHINA Yangming)

It is a contactless switch composed of microelectronic circuits, discrete electronic devices, and power electronic power devices. The isolation device is used to realize the connection between the control end and the load end.

air circulation system

1. Circulation air duct: mainly used for air exchange in the working room, consisting of an air inlet, circulation motor, impeller, and air outlet.

2. Taiwan, CHINA Yizheng long-axis motor: The structure is very simple and strong, with excellent speed regulation performance, long life, easy maintenance, low noise, and there are no series of problems caused by brushes, so this kind of motor has many advantages in the control system. Big application.

3. Motor wind wheel: drives air flow.

4. Pneumatic electronic valve: used to switch dampers in high temperature areas, low temperature areas and test areas.

Control System

1. Microcomputer program controller

Program editing and looping, the program can program 1,000 groups, each group has 100 segments, each segment can be set for 32,700 hours, and can be cycled 999,999 times; it supports free combination of programming output, serial and parallel and other difficult controls, and the internal logic programming composite mode can reach 12 groups

2. Sensor PT-100: collection temperature range is -70℃ï½+180℃

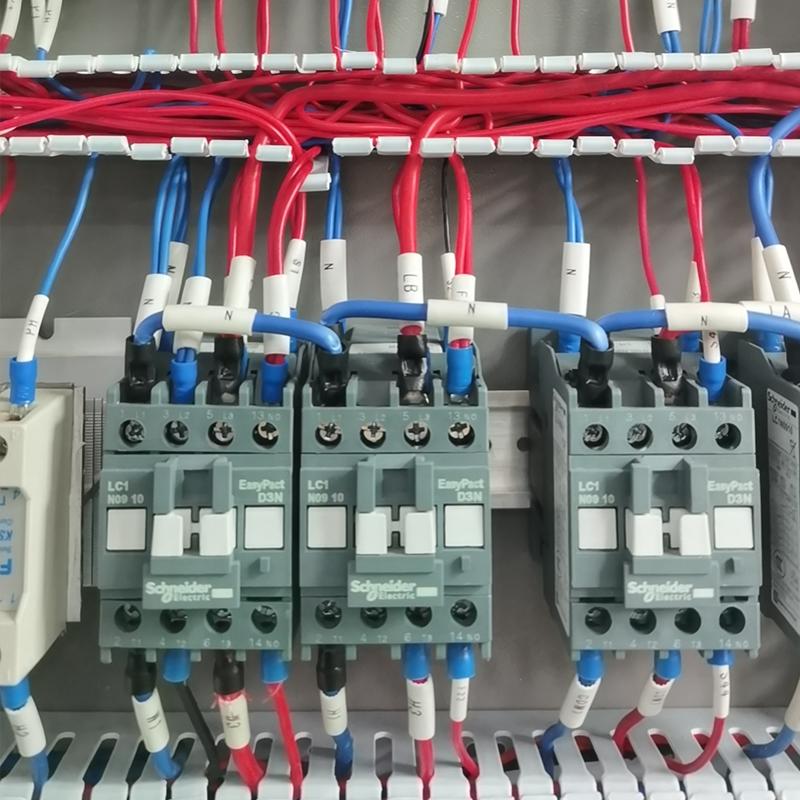

3. AC contactor: Schneider; on-off protection: compressor, heater

4. Thermal relay: Schneider; compressor overcurrent and overheating protection

5. Main power switch: Chint; instrument main power on-off control

6. Button switch: CHINA Chaoneng; controller, lighting power control

7. Wire and cable: Jin Lianyu

8. Wiring strip: Japanese IDEC; wiring port

9. Number management

- 1Principle, Structure and Application of Humidity Chamber

- 2Principle and Application Analysis of Fluorine Resin thermostatic Box

- 3Analytical magnetic material programmable Humidity Chamber, principle, application and selection

- 4Principle, application and selection of luggage Humidity Chamber

- 5Principle, application and selection of field effect transistor programmable Humidity Chamber

- 6Principle, application and selection of programmable Humidity Chamber for die casting

- 7Humidity cabinet test equipment

AP-HX-1000F

AP-HX-1000F