APKJ 2AP-CJ-100C Two-box high-low temperature Impact test box air-cooled -65 ℃

Apkjgroup 2AP-CJ-100C Thermal Shock Test ChamberSPEC

Apkjgroup 2AP-CJ-100C Thermal Shock Test ChamberDetails

Apkjgroup 2AP-CJ-100C Thermal Shock Test ChamberPacking list

- SKU

- NB042384

- Temperature range

- -65 ℃~ + 150 ℃ (air-cooled)

- Temperature Fluctuation

- ±0.5℃

- Temperature deviation

- ±2.0℃

- Weight

- About 750kg

- Inner Volume

- 100L

- Liner size

- 500*500*400mm

- Dimensions

- 1500*1950*1850mm

- Low Temperature Impact Range

- -10 ℃~ -65 ℃ (optional)

- High Temperature Impact Range

- 60 ℃~ 150 ℃ (arbitrarily adjustable)

- Test environmental conditions

- Ambient Temperature around the machine is maintained between + 25~ + 30 ℃, Relative Humidity: ≤ 85%; air pressure: 86kPa~ 106kPa normal atmospheric pressure.

- High Temperature Impact Range

- RT~+195°C

- Heating rate

- +50℃→+195℃ ≤40min

- Low Temperature Impact Range

- RT~-75°C

- Cooling rate

- + 20 ℃ → -75 ℃ ≤ 90min

- Test method

- Place the product in the gondola test area, two boxes of mobile heat & cold shock, safe air pressure to drive the test object up and down Impact.

- Temperature recovery time

- ≤ 5min; the conversion temperature only needs ≤ 10s (the movement time of the hanging basket: within 3 seconds)

- Impact exposure time

- ≥30min

- Enclosure Material

- The outer material can be selected from SUS304 good stainless steel or fine powder paint treatment

- Liner material

- Stainless Steel Plate (SUS #304)

- Box insulation material

- Rigid polyurethane foam

- Air conditioning channel

- Fan, heating device, evaporator, damper, temperature transducer

- Specimen shelf

- 1 set, a total of two layers (with four hooks) bearing 25KG (please indicate when placing an order for larger bearing)

- Lead Hole

- (Optional) 1, located on the left side of the box, with a round hole with a size of φ50mm

- Test chamber door

- Single open, left hinge, right handle

- Circulating Fan

- High temperature/ring temperature exposure: 3φ, 400W, centrifugal; low temperature exposure: 3φ, 400W, centrifugal

- Control Panel

- Controller display, fault indicator, timer, USB or R232 interface, over-temperature protection setter, main power switch

- Machinery room

- Refrigeration unit, connected to drainage device, exhaust fan

- Distribution control cabinet

- Total power leakage circuit breaker, Controller, switchboard, cooling fan, high and low temperature Circulating Fan motor

- Heating system

- Nickel chromium alloy heating wire heating device

- Heating control mode

- No touchpoint equal period pulse width modulation, SSR (solid state relay)

- Power cord holes and drain holes

- On the back of the box

- Refrigeration system

- France Taikang or Japan Hitachi fully enclosed low noise rotary compressor

- Evaporator

- finned tube heat exchanger

- Condenser

- Shell and tube heat exchanger

- Throttle device

- Thermal expansion valve, capillary tubing

- Evaporative condenser

- Stainless steel brazed plate heat exchanger

- Refrigerator control mode

- Control system PLC (programmable logic Controller) automatically adjusts the operating conditions of the refrigerator according to the test conditions, compressor return air chill down circuit, energy regulation circuit, condensing pressure control valve

- refrigerant

- R404a/R23

- Controller

- Programmable Controller, touch screen input, different high and low temperature Impact temperature points can be arbitrarily set according to customer requirements to meet different needs for testing

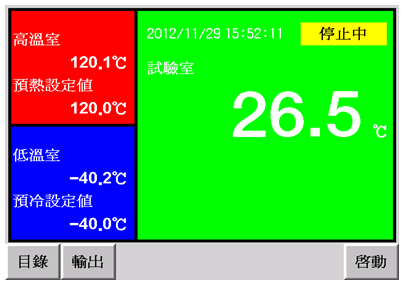

- display

- LCD liquid crystal display

- Operation mode

- procedural method

- Setup method

- All Chinese liquid crystal display (Chinese and English can be switched) LCD touch panel (resistant to 100.000 line drawing test)

- Program Capacity

- Up to 120 groups, each program is divided into three areas, three areas and 3 segments. Each command can reach 999 times; the program segment time is set to 0~999Hour59Min.

- Display resolution

- Temperature: 0.1 ℃; Time: 0.1min

- Electrical input

- Thermocouple

- storage device

- USB and R232 communication interface

- Control mode

- Anti-integral saturation PID, fuzzy algorithm; BTC equilibrating temperature control mode

- Curve recording

- Real-time display of graphics during program execution Linear dispersion

- subsidiary function

- With power-off program memory, it automatically starts and continues to execute program functions after power-back, with date, time adjustment, reservation start, shutdown function and screen lock (LOCK) function.

- Environmental conditions

- Temperature: 5 ℃~ 35 ℃; Relative Humidity: ≤ 85%; air pressure: 86kPa~ 106kPa normal atmospheric pressure.

- Air source pressure

- ( 5 ~ 7 ) kg / cm2

- Air source connecting pipe diameter

- fo8mm

- Flow rate

- 0.1m3/min

- Maximum Power

- About 12.0KW [Voltage range: no more than +/- 10%]

- Storage environment

- When the equipment is not working, the temperature of the environment should be kept within 0 ℃~ + 45 ℃; when the Ambient Temperature is lower than 0 ℃, the water remaining in the equipment should be discharged cleanly to prevent the water in the pipeline from freezing and damaging the pipeline.

- Maximum current

- 18A

Control instruments

The 7-inch ultra-large touch AP-950 programmable temperature controller self-developed by Aipay has a full touch screen controller, touch screen input, and different high-low temperature impact temperature points can be set arbitrarily according to customer requirements to meet the different needs of testing. (With temperature alarm display, real-time temperature curve display).

Applications

It is widely used in electronic and electrical components and plastic industries, automation parts, communication components, auto parts, metals, chemical materials, plastics and other industries, national defense industry, aerospace, military industry, BGA, PCB base wrench, electronic chip IC, semiconductor ceramic and polymer materials for physical change testing. It is used to test the degree to which a material structure or composite material can withstand in an instantaneous continuous environment of extremely high temperature and extremely low temperature, so as to test the chemical or physical changes caused by its thermal expansion and contraction in the shortest time.

Features

The two boxes of equipment are divided into two parts: high temperature area and low temperature area, the test product is placed in the basket, and the basket moves the test product into the high temperature area or low temperature area for weighing when impacting, and the test product is dynamic.

The two-box mobile hot and cold shock, the safe air pressure drives the test object up and down to and fro.

Adopt Japanese original imported color touch LCD Chinese/English microcomputer temperature controller.

Paperless recording function, with real-time display of temperature shock test change curve graph and record dual functions.

The movement time of the hot and cold shock mechanism is within 10 seconds, and it can meet MIL, LEC, JIS and other specifications.

The thermal shock temperature recovery time is within 5 minutes, which can meet the relevant test specifications.

It adopts HFC environmentally friendly refrigerant and binary ultra-low temperature freezing system design, which has fast cooling and high efficiency.

Meet the criteria

GB/T2423.1-2008 Test method of low tempemture test

GB/T2423.2-2008 Test method of high temperature test

GB/T2423.22-2012 Test of temperature chantge

GJB150.5-86 Test of temperature shock

GJB360.7-87 Temperature Shock Test of temperature shock

GJB367.2-87 Test of temperature shock

QC/T17-92、EIA364-32、IEC68-2-14等

Advantages of insulation

Box insulation material:rigid polyurethane foam,Its advantages are:

1. Effective energy saving, no gap after filling, strong bond after curing.

2. Shockproof and compression-resistant, no cracking, no corrosion, no falling off after curing.

3. It has ultra-low temperature thermal conductivity, weather resistance and heat preservation.

4. Effective insulation, sound insulation, waterproof and moisture-proof after curing.

5. Good waterproof performance, because the foam hole is closed, the sealing rate is 95%, and the rainwater will not seep through the hole.

The name and function of each part of the Test Chamber

(1) High temperature chamber: used to store heat

(2) Laboratory: the part where the sample is placed for testing

(3) Low temperature chamber: used to store cold energy

(4) Main power board: including main power switch, sample power control terminal, external alarm output terminal, test end output terminal, temperature arrival output terminal, RS-232 communication interface, operation panel cover lock

(5) Operation board: including controller, fault indicator, over-temperature protection setter, temperature Recorder (optional)

(6) Power distribution room: install electrical components

(7) Mechanical room: install refrigeration units and exhaust fans

(8) Air intake: Inhale outside air when the ambient temperature is exposed

(9) Exhaust port: Exhaust hot gas from the mechanical room and the test room

(10) Temperature Recorder (optional) records the temperature of each chamber of the temperature shock Test Chamber

Safety protection device

1. Refrigeration system:Compressor overpressure, compressor overheating, compressor overflow, circulating cooling water supply underpressure

2. Laboratory:Laboratory temperature too high and too low protection (built-in controller), laboratory temperature too high and too low protection, laboratory door opening protection

3. Others:Total power phase sequence and phase loss protection relay, leakage circuit breaker, specimen power control terminal, external alarm output terminal, high/low temperature room over-temperature protection switch, high/low temperature room over-temperature protection (built-in controller), circulating fan thermal relay, motor temperature switch, compressed air pressure switch, exhaust valve

Other configurations

※The user is required to configure the corresponding capacity air or power switch at the installation site, and this switch needs to be independent for the use of this equipment AC380V power supply requirements:

1. Three-phase four-wire + protective ground wire

2. Voltage range: AC (380±10)V

3. Allowable fluctuation range of frequency: (50±0.5) Hz

4. The grounding resistance of the protection wire is less than 4Ω

This solution does not include the installation of ventilation pipes, power supply (leakage switch), air source (Air Compressor), water source (bottled water or water connection pipe) and other equipment external environment items

- 1Precision heat & cold shock testing device

- 2Principle, Application and Selection of Main board Thermal Shock Test Chamber

2AP-CJ-100C

2AP-CJ-100C