BEVS 1306/2 Intelligent Pendulum hardness tester with Persoz pendulum

SEBEVS BEVS 1306/2 Pendulum hardness testerSPEC

BEVS BEVS 1306/2 Pendulum hardness testerDetails

BEVS BEVS 1306/2 Pendulum hardness testerPacking list

- SKU

- NB042500

- Swing bar type

- Persoz pendulum

- Persoz swing mass

- 500±0.1g

- Persoz swing cycle

- 1±0.01s

- Persoz ball diameter

- 8mm

- Persoz Glass Swing Time

- 430±10s

- Persoz Glass Swing Count

- 430±10T

- Persoz start and end swing angle

- 12°/4°

- Power frequency

- 100~240V(50/60Hz)

- dimensions

- 350*450*750mm

- Host weight

- 31KG

Introduction

BEVS 1306/2It is a newly designed, humanized, intelligent, high-precision, full-touch screen control damping intelligent pendulum Hardness Tester for testing coating hardness, the instrument has the best automatic control, and is widely used to measure the hardness of coatings and similar material surfaces.

BEVS 1306/2Intelligent pendulum Hardness Tester is to use the damping time of the pendulum (K pendulum or P pendulum) oscillation on the sample to represent the hardness of the sample, the slower the amplitude attenuation of the vibration on the sample with the smoother the surface and the smaller the friction resistance, the higher the hardness of the material, and vice versa;

The instrument has a series of intelligent functions such as automatic identification of horizontal status before the test, automatic monitoring of the vibration of the surrounding environment and whether the temperature and humidity of the environment meet the test requirements, automatic alarm, etc., to ensure the automation of the test and the high accuracy of the measurement results, and to avoid errors caused by human and environmental factors.

BEVS 1306/2The intelligent pendulum Hardness Tester is an instrument for universities, scientific research and QC personnel to measure hardness, especially in the development and application of automotive coatings, which can provide very accurate test data and assist users to complete effective and accurate testing work.

Features

Color touch screen display

Fully automatic operation

Temperature and humidity environment monitoring

Automatic recognition of the pendulum

Automatic recognition of levels

Vibration warning

Data storage and output (number of measurements, maximum value, minimum value, comparison chart)

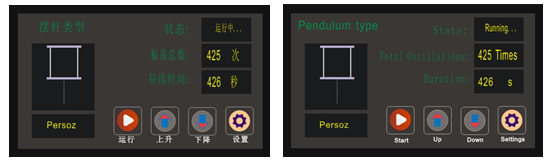

Interface diagram

1) Main interface: real-time display of the status of the pendulum, the total number of oscillations and the duration

2) Setting interface: You can set relevant parameters and calibration

Meets standards

ISO 1522,ASTM D4366,NF T30-016,BS 3900 E5,DIN 53157

- 1ISO 《Paints and Varnishes - Pendulum Damping Test》

- 2NF 《Paints and varnishes - Pendulum damping test》

- 3EN ISO 1522-2006《Paints and varnishes - Pendulum damping test (ISO 1522:2006)》

- 4NF EN ISO 1522-2007《Paints and varnishes - Pendulum damping test.》

- 5ASTM D4366-2021《Standard Test Methods for Hardness of Organic Coatings by Pendulum Damping Tests》

BEVS 1306/2

BEVS 1306/2