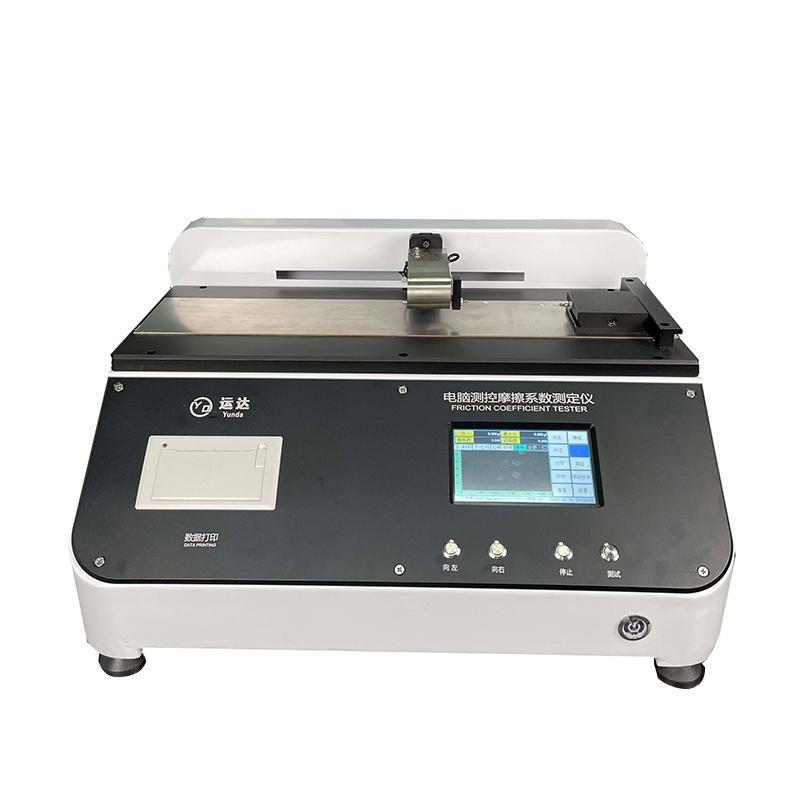

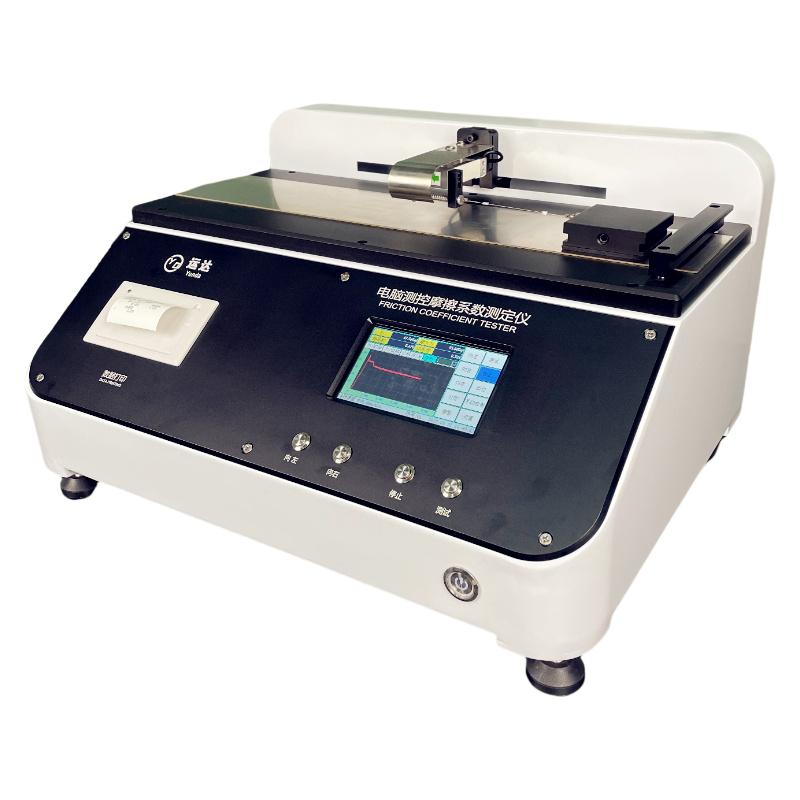

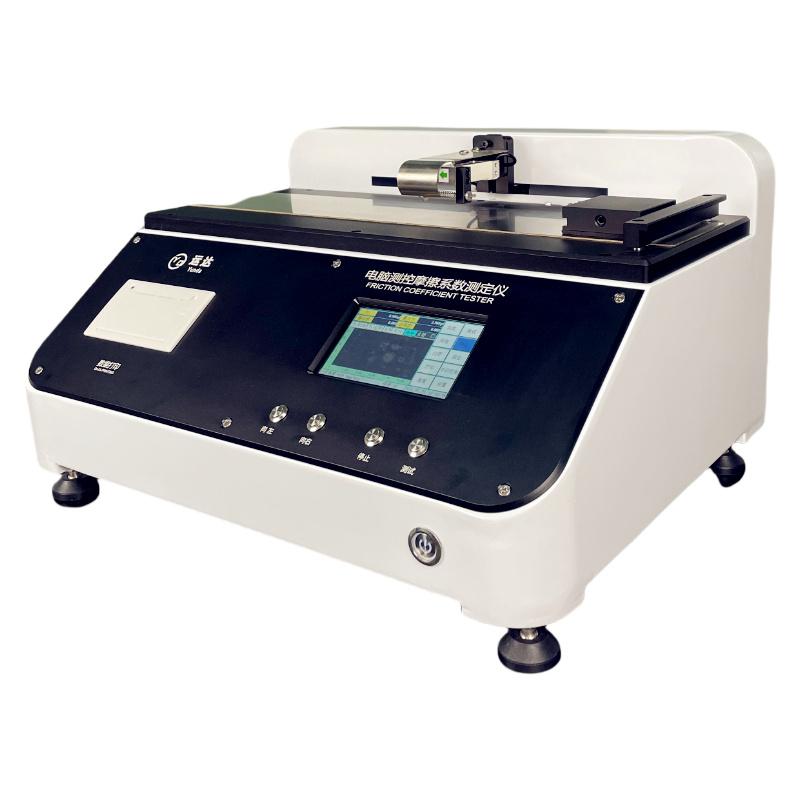

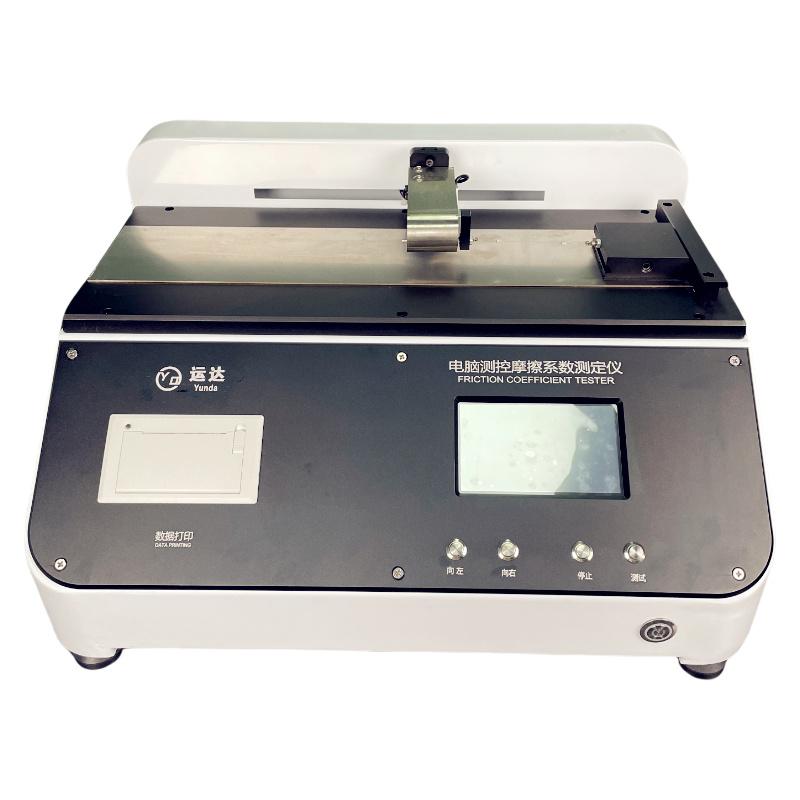

YD-MCY Friction Coefficient Meter 0.01~ 10N

SE-

CHINA NBC-3009 coefficient of friction Tester, film paper fabric friction test$ 1089.00SE

CHINA NBC-3009 coefficient of friction Tester, film paper fabric friction test$ 1089.00SE -

JINGWEN JW120C paper Friction Coefficient Meter range 0-5N$ 1439.00SE

JINGWEN JW120C paper Friction Coefficient Meter range 0-5N$ 1439.00SE -

Taichang TC-MXD-02 Touch screen Friction Coefficient Meter 0~5N$ 1497.00SE

Taichang TC-MXD-02 Touch screen Friction Coefficient Meter 0~5N$ 1497.00SE -

CHENCHI MXD-02 Computer Friction Coefficient Meter Range 0-5N$ 2225.00SE

CHENCHI MXD-02 Computer Friction Coefficient Meter Range 0-5N$ 2225.00SE -

CHENCHI MXD-01 Friction Coefficient Meter range 0-5N$ 1471.00SE

CHENCHI MXD-01 Friction Coefficient Meter range 0-5N$ 1471.00SE

YunDa YD-MCY Friction Coefficient MeterSPEC

YunDa YD-MCY Friction Coefficient MeterDetails

YunDa YD-MCY Friction Coefficient MeterPacking list

- SKU

- NB042702

- Power supply Voltage

- AC220V±10% 50HZ 2A

- Force range

- 0.01~10N

- resolution

- 0.01N

- error of indication

- ±2%

- Specimen thickness

- ≤0.2mm

- Slider size

- 63mm×63mm

- Slider Mass

- 200g±2g

- Test bench size

- 170mm×225mm

- Slider stroke

- 170mm

- Slider traverse speed

- 0-500mm/min (adjustable)

- Test speed recommended

- (100±10) mm/min

Introduction

The coefficient of frictIon Meter is designed for the static friction coefficient of plastic film and sheet, rubber, paper, cardboard, woven bag, fabric style, metal material composite belt for communication cable and optical cable, conveyor belt, wood, coating, brake pad, wiper and other materials when sliding and dynamic coefficient of friction developed. Manufactured based on the national standard GB/T10006 "Plastic - Film and Sheet - Determination of Coefficient of Friction", in line with GB/T 17200, GB/T 22895, ISO 8295, ASTM D1894, TAPPI T816, GB/T 2792 and other standards. The professional testing equipment of the quality inspection department and the production enterprise can provide you with accurate test results.

Features

1. Stepping motor is adopted, with low noise and precise control

2. It adopts a color large-screen touch LCD display to display various data in real time

3. Simple parameter setting, convenient and reliable testing

4. Get the measurement results directly, including the average value and standard deviation

5. High degree of automation: capable of data processing and motion control, automatic reset and overload protection

6. Data communication: the instrument has a standard wan interface, which can provide data communication for the upper computer comprehensive report system

working principle

Clamp the strip-shaped test sample with a sample clamp, and wrap the slider with the sample to be tested, then place the slider on the hanging hole of the sensor, and under a certain contact pressure, drive the rack through the motor to move the sensor. That is to make the two test surfaces move relative to each other. The force signal measured by the sensor is amplified by the integrator and sent to the Recorder, and the coefficient of dynamic friction and the coefficient of static friction are recorded respectively.

- 1GB/T 44572-2024《Biaxially oriented polyethylene (BOPE) film》

- 2GB/T 19787-2025《Encasement material, polyolefin thermal cissing film》

- 3GB/T 16311-2024《Specification and test method for road traffic markings》

- 4SY/T 6863-2012《Calibration method of mudcake coefficient device》

- 5JT/T 763-2017《Pendulum friction tester》

- 6GB/T 41899-2022《General quality requirements for coated tinplate and ECCS used in food container》

- 7GB/T 10006-1988《Plastics--Film and sheeting--Determination of the coefficients of friction》

- 8GB/T 10006-2021《Plastics—Film and sheeting—Determination of the coefficients of friction》

- 9ASTM C1028-2017《Standard Test Method for Determining the Static Coefficient of Friction of Ceramic Tile and Other Like Surfaces by the Horizontal Dynamometer Pull-Meter Method》

YD-MCY

YD-MCY