KAIRDA NDT370 Pen Electromagnetic Ultrasonic Thickness Gauge, Room Temperature Probe

SEKairDa NDT370 Pen electromagnetic ultrasonic Thickness GaugeSPEC

KairDa NDT370 Pen electromagnetic ultrasonic Thickness GaugeDetails

KairDa NDT370 Pen electromagnetic ultrasonic Thickness GaugePacking list

- SKU

- NB042709

- Can detect workpiece material

- Carbon steel, cast steel, alloy steel, stainless steel, copper, aluminum, bowl and other conductor materials

- Receive gain

- s100dB

- Measurement range

- 1~ 240.0mm (Measurement range depends on the material)

- Highest resolution

- 0.01mm

- Room temperature probe

- < 150 ℃, 4MHz, mainly used to detect fine-grained materials, such as low-carbon steel, aluminum, etc

- Error range of measurement equipment

- Film thickness < 10mm, error + 0.05mm; Film thickness > 10mm error ± (0.01 + H/200) mm (H is the workpiece Film thickness value)

- Minimum diameter (curvature) of workpiece can be detected

- 8 mm

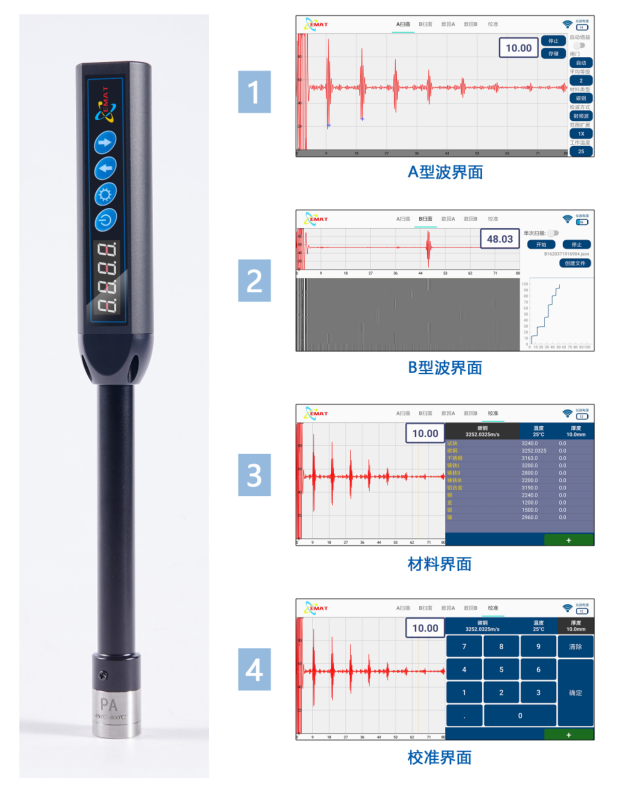

- Waveform display

- Positive half wave, negative half wave, radio frequency wave

- Power

- Built-in battery, Working time > 6 hours, can be used with power bank

- Data storage

- Can store A scan data, B scan data, unlimited storage quantity

- Measurement mode

- Automatic mode, manual mode, semi-automatic mode

- Sound wave type

- Shear wave (shear wave)

- Communication interface

- USB communication, software lifetime free upgrade

- Speed of sound

- Speed of sound can be reversed in the case of unknown material Speed of sound

- Host Weight

- 250G (with room temperature probe)

- Host storage

- Storage Temperature range 0~ + 40C

- High temperature compensation

- Speed of sound automatic compensation function

- Speed adjustment range of sound waves

- 1000~9999m/s

- Operating temperature range

- -10~+50°C

Introduction

Pen Electromagnetic Ultrasonic Thickness Gauge is an ultra-small, non-contact thickness Measurement Instrument without acoustic coupling agent, which can realize the thickness measurement of metal or magnetically permeable substances.

Pen-type electromagnetic ultrasonic Thickness Gauge brings together modern high-tech such as ultrasonic flaw detection, thickness measurement, computer, electronics, mold, technology, etc., and realizes the combination of these high-tech. It provides the industry with a flaw detection and thickness measurement integrated machine with more superior performance and more powerful functions.

Features

WIFI wireless connection

Can measure up to 800° high temperature

USB communication online transmission

No contact, no grinding

Coupling-free, coating-penetrating

Measure magnetic and non-magnetic gold

Metal material built-in material sound velocity

Product Structure

Features A/B scanning software to detect internal defects

The software has real-time waveform display and A/B scanning functions, which can detect internal corrosion.

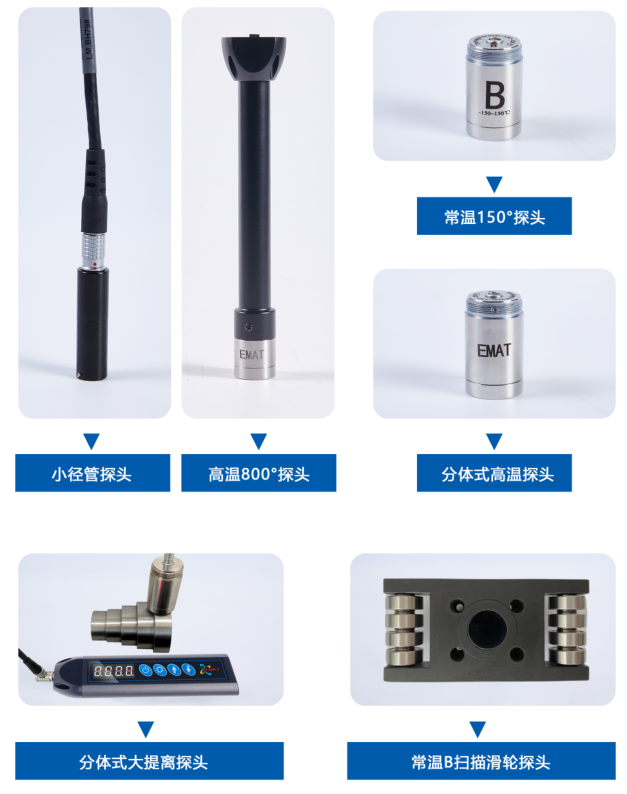

Optional probe

- 1JJF 1224-2009《Calibration Specification for Reinforced Concrete Covermeter and Floorslab Thickness Tester》

- 2JJF 1126-2004《Calibration Specification for Ultrasonic Thickness Instruments》

- 3JB/T 11604-2013《Non-destructive testing instruments.Ultrasonic thickness gauge》

- 4GB/T 33888-2017《Non-destructive testing instruments—Characterization and verification of ultrasonic thickness measuring equipment》

- 5GB/T 40332-2021《Non-destructive testing—Ultrasonic testing—Characterization and verification of ultrasonic thickness measuring equipment》

NDT370

NDT370