Pushen DIN8 Desktop Viscosity cup with bracket, customized

SEPushen DIN8 customization DIN cup with bracketSPEC

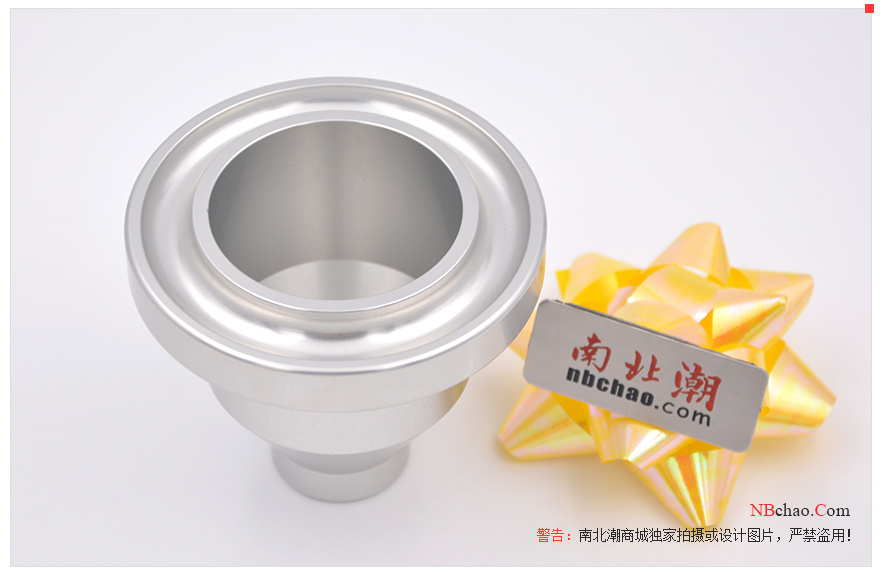

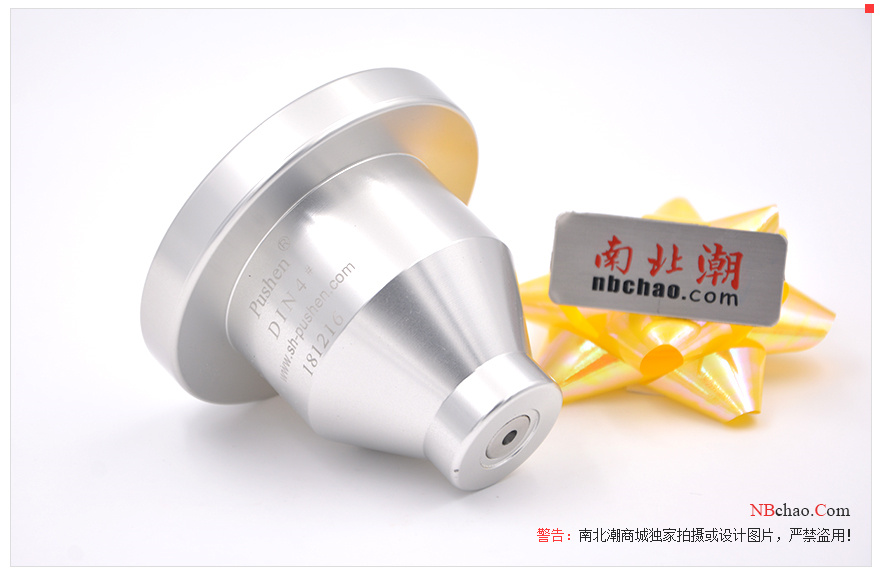

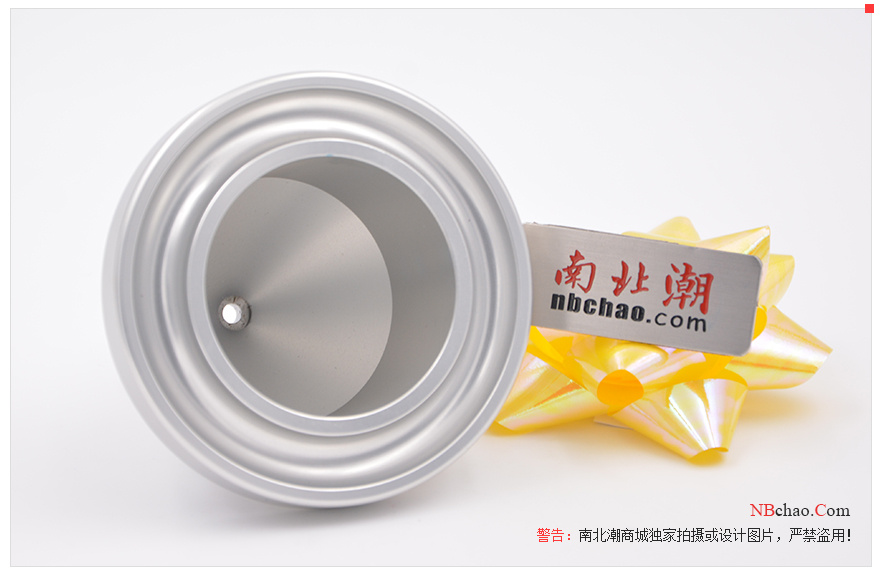

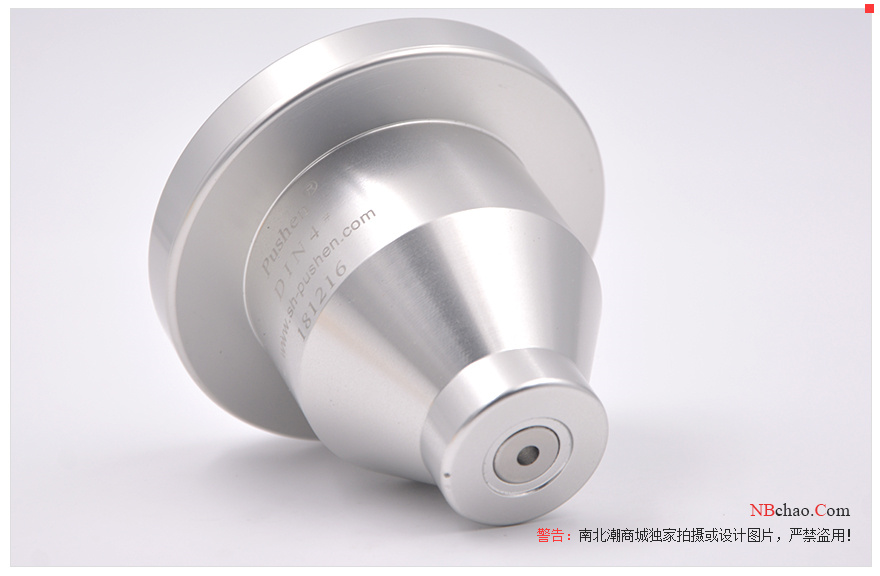

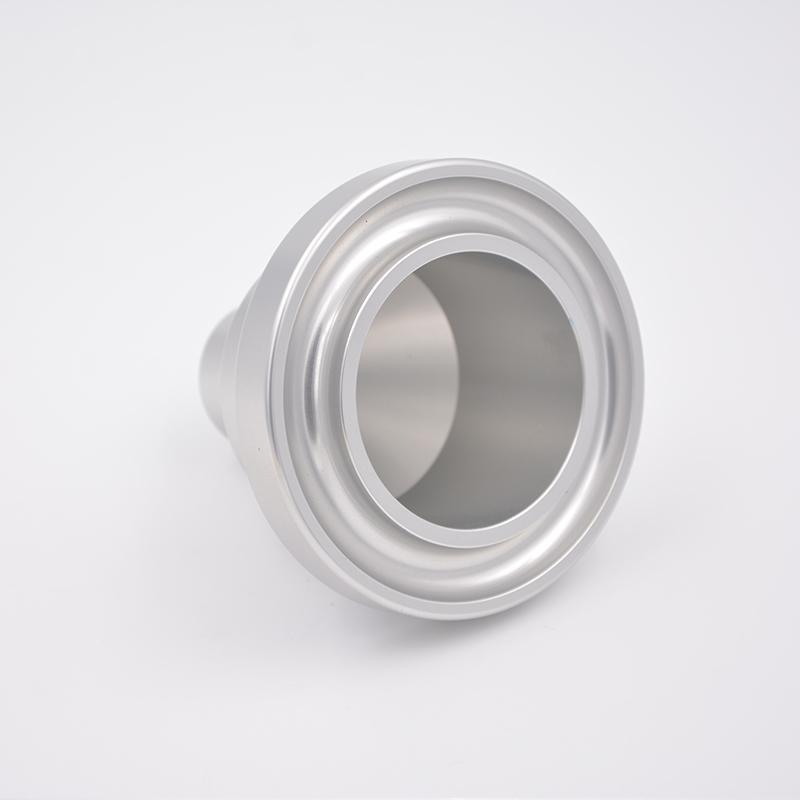

Pushen DIN8 customization DIN cup with bracketDetails

Pushen DIN8 customization DIN cup with bracketPacking list

- SKU

- NB004278

- Flow hole diameter

- 8mm

- Cup height

- 73mm

- Cup width

- 55mm

- Cup body material

- Aluminum anode oxidation

- Filter material

- stainless steel

- Applicable standard

- DIN 53211

Introduction to DIN Cup

The Pushen DIN cup is a desktop Viscosity Cup, and the test is relatively simple. The production design of this DIN Viscosity Cup is based on the relevant regulations of the German Standardization Committee DIN53211 (Deutsches lnstitut fur Normung), and is used to measure the viscosity of inks, paints, paints, etc. There are four types of Pushen DIN cups : No. 2, No. 4, No. 6, and No. 8. The corresponding measuring apertures are 2mm, 4mm, 6mm, and 8mm respectively . They are suitable for measuring different viscosity ranges. They are made of stainless steel and have good durability. corrosive.

Desktop DIN cup: Let the liquid flow through the nozzle, usually using this method to measure and grade its viscosity relatively.

Viscosity Definition: The ability of a liquid to resist its tendency to flow is called viscosity. For the coatings industry, viscosity is a critical parameter.

Instructions

Very easy to use benchtop DIN cup made of anodized aluminum with a stainless steel orifice for measuring the consistency of paints, varnishes and similar products.

The measured kinematic viscosity is usually expressed in seconds required for outflow. The efflux time can be converted to centistokes (cSt) by a standard formula.

Centistokes (cSt) = K value × outflow time - (C value ÷ outflow time), centipoise (cP) = centistokes × specific gravity

Viscosity unit

The kinematic viscosity value is usually expressed in seconds after the flow is completed, and can also be converted into centistokes (Centistokes) through the viscosity conversion disc.

The unit of kinematic viscosity is stokes, Stokes, when the fluid viscosity is 1P (poise), the kinematic viscosity with a density of 1g/cm3 is 1 Stokes.

cSt is the abbreviation of centistokes, called centistokes, which is one hundredth of 1 Stokes. Centistokes (cSt) is the smallest unit of kinematic viscosity.

Precautions for use

When using Pushen/Pushen 2/4/6/8 DIN cups, a stopwatch with relatively high precision is required.

Pictures

DIN8 customization

DIN8 customization