TRUIT TR 5001/1 adhesion Cross Hatch Cutter 1mm/6 teeth

SE-

QFH Cross Hatch Cutter 1/2/3 mm Tooth QFH Cross Hatch Cutter 6 Tooth$ 188.00SE

QFH Cross Hatch Cutter 1/2/3 mm Tooth QFH Cross Hatch Cutter 6 Tooth$ 188.00SE -

MODERNER QFH 1mm (5 slots) Cross Hatch Cutter Number 6

MODERNER QFH 1mm (5 slots) Cross Hatch Cutter Number 6 -

Germany erichsen 295/I Lacquered Cross Hatch Cutter Set 6 teeth/1mm$ 980.00SE

Germany erichsen 295/I Lacquered Cross Hatch Cutter Set 6 teeth/1mm$ 980.00SE -

Shanghai PUSHEN 1mm * 6 Tooth Cross Hatch Cutter$ 150.00SE

Shanghai PUSHEN 1mm * 6 Tooth Cross Hatch Cutter$ 150.00SE -

TQC VF2355 cross-cut blade 6 teeth 1mm for CC1000 series$ 835.00SE

TQC VF2355 cross-cut blade 6 teeth 1mm for CC1000 series$ 835.00SE

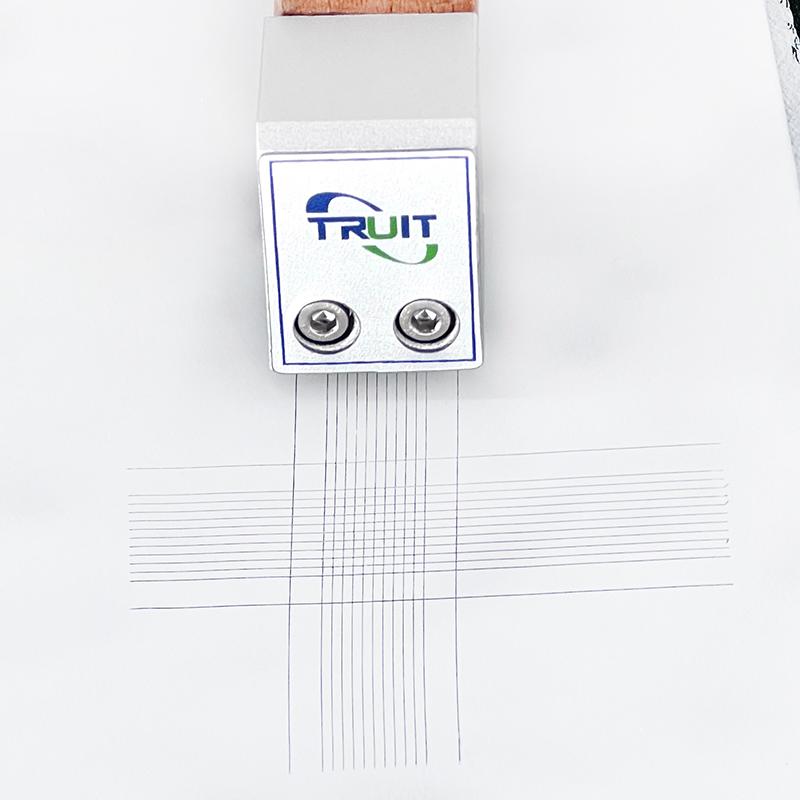

TRUIT TR 5001/1 Single Knife Face Cross Hatch CutterSPEC

TRUIT TR 5001/1 Single Knife Face Cross Hatch CutterDetails

TRUIT TR 5001/1 Single Knife Face Cross Hatch CutterPacking list

- SKU

- NB043286

- Number of teeth

- 6 teeth

- Tooth spacing

- 1mm

- Applicable film thickness environment

- Hard substrates (metal) with film thickness < 60 μm

- Handle material

- wood

- Cutter head material

- High quality alloy steel

- Application standard

- GB/T 9286, ASTM D3359, ASTM D3002 and ISO 2409 standards

- Blade top width

- Less than 0.05mm

- blade angle

- 30°±1°

Introduction

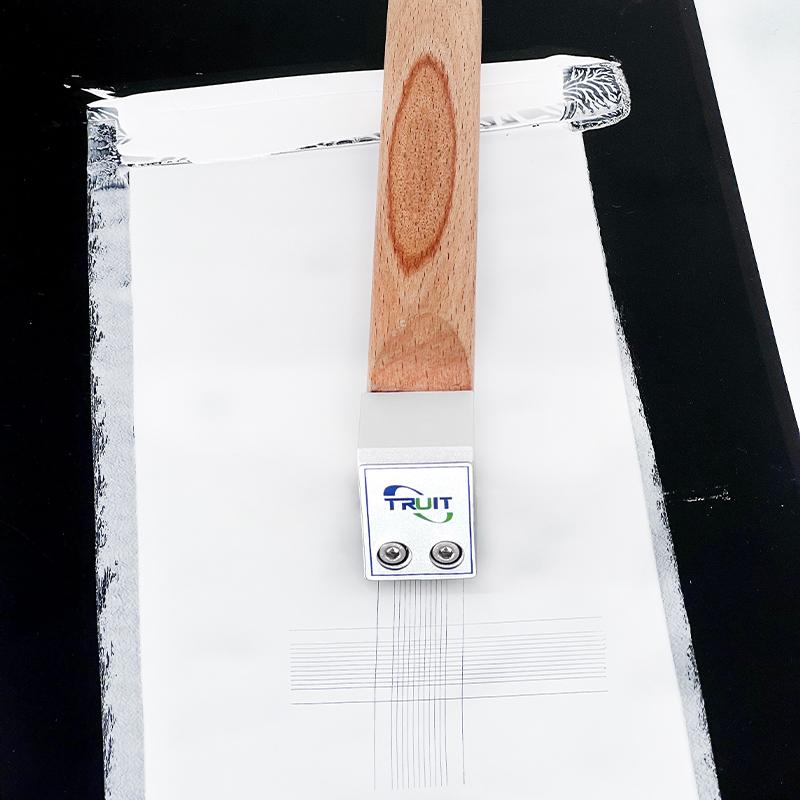

The adhesion scratcher is a tool used to evaluate the adhesion of coatings and is usually used for coating quality inspection and coating process control. It assesses the adhesion of a coating by scratching the surface of the coating in a series of grid patterns, then using an appropriate tool to cover the scratched area with tape and then quickly removing the tape.

Adhesion scorers can be used for on-site testing during the coating process or for coating research and quality control in a laboratory environment. It is a simple and rapid method for evaluating the adhesion of coatings and provides qualitative or semi-quantitative information on the strength of the bond between the coating and the substrate.

TR 5001/1 single-blade scratcher is made of wooden handle and high-quality alloy steel blade, with a tooth spacing of 1mm and a tooth count of 6.

Features

Ergonomic handshake design for effortless use

Blades are easily replaceable

Blade material: high quality alloy steel

Blade top width: less than 0.05mm

Blade angle: 30°±1°

Series parameter table

| model | Knife distance (mm) | Number of teeth | working surface |

| TR 5001/1 | 1 | 6 | 1 |

| TR 5001/2 | 1 | 11 | 1 |

| TR 5001/3 | 1.5 | 11 | 1 |

| TR 5001/4 | 2 | 6 | 1 |

| TR 5001/5 | 3 | 6 | 1 |

Note: The multi-edged cutting knife with 1mm spacing is suitable for hard substrates (metal) with paint film thickness <60μm.

The multi-edged cutting knife with a spacing of 2mm is suitable for hard substrates with a paint film thickness of 61 μm ~ 120 μm or soft substrates (wood, plastic) with a thickness <120 μm.

The multi-edged cutting knife with a spacing of 3mm is suitable for hard or soft substrates with a paint film thickness of 121μm to 250μm.

- 1JJF 2163-2024《Calibration Specification for Paint Film Scribers》

- 2SJ 20910A-2018《General specification for powder spraying coating》

- 3NF 《Paints and varnishes - Cross-cut test》

- 4 2097-2015《Paints and varnishes - Cross-cut test》

- 5SY/T 4106-2016《Specification of solvent - free polyurethane coatings for steel pipelines and tanks》

- 6 002-2017《Water based polyurethane coatings》

- 7GB 10810.4-2012《Uncut finished spectacle lenses - Part 4: Specifications and test methods for anti-reflective coatings》

- 8GB/T 13217.7-2023《Test method for adhesion to substrate of ink with tape》

- 9GB/T 4893.4-2023《Test of surface coating of furniture—Part 4:Determination of adhesion by cross-cut》

- 10GB/T 42541-2023《Coated steel pipes for gas piping》

TR 5001/1

TR 5001/1