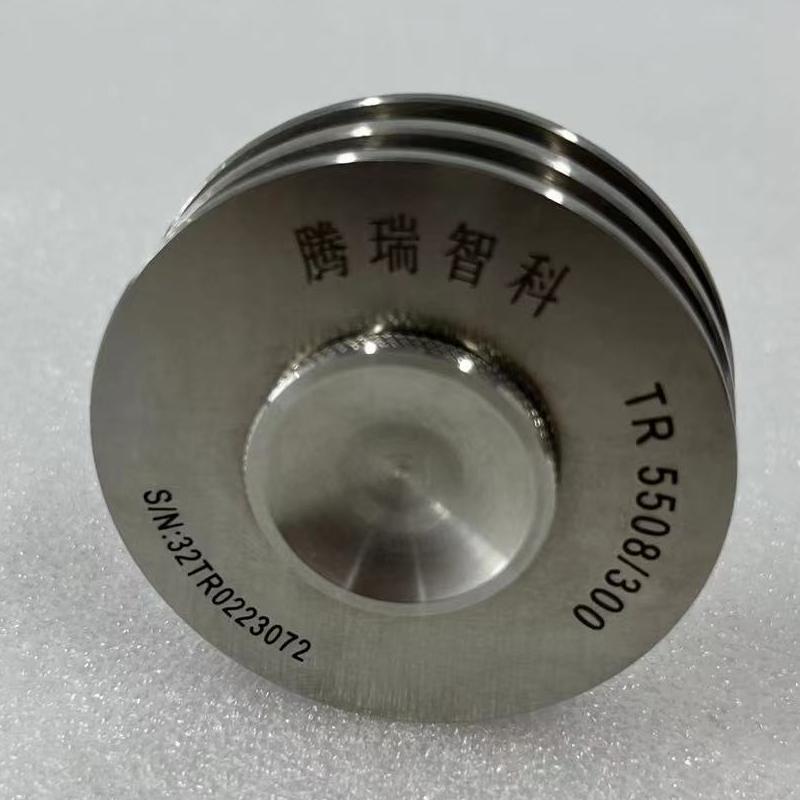

TRUIT TR 5508/2000 wet-film thickness measuring wheel, range 0~2000μm

SETRUIT TR 5508 / 2000 Wet Film Thickness GaugeSPEC

TRUIT TR 5508 / 2000 Wet Film Thickness GaugeDetails

TRUIT TR 5508 / 2000 Wet Film Thickness GaugePacking list

- SKU

- NB043325

- range

- 0 ~ 2000m

- Graduation

- 100µm

Introduction

The wet-film thickness measuring wheel is a tool for measuring the thickness of the wet Coating film. It has a wheel-like structure with a dial or scale line for reading the wet film thickness. It is made of stainless steel. The thickness value of the wet Coating can be determined by comparing the scale on the dial with the amount of Coating adsorption.

Roller Thickness Gauges are easy to use and suitable for many wet Coating application scenarios, such as Coating construction, surface coating and Coating thickness monitoring. Using roller Thickness Gauges can quickly and accurately assess the thickness of wet Coatings to ensure mass and conformity of Coating construction.

The range of TR 5508/2000 is the thickness measurement range of 0~2000μm, and the Graduation is 100μm.

Standards

Designed according to GB/T 13452, ASTM D1212, ASTM D4414 and ISO 2808 standards.

Structure

The Wet Film Wheel can quickly confirm the thickness of the wet-film stage. The Thickness Wheel consists of a wheel, the inner circle forms a centrifugal circle with two outer wheels, and the three wheels are at the same point at zero position, and the horizontal scale distance of the inner circle is lower than the wheel surface at any position. When the coating layer, immediately the measurement wheel of the gap position with the largest difference between the inner and outer rims is placed on the surface, and then the inner and outer wheels keep the same line and roll along the zero position in contact with the surface, check the position where the inner rim starts to contact the Coating, and the wet film thickness can be obtained from The scale reading on the outer rim is indicated.

Series model parameter table

| Model | Rand | Graduation |

| TR 5508/25 | 0~25μm | 1μm |

| TR 5508/50 | 0~50μm | 2μm |

| TR 5508/100 | 0~100μm | 5μm |

| TR 5508/200 | 0~200μm | 10μm |

| TR 5508/300 | 0~300μm | 15μm |

| TR 5508/500 | 0~500μm | 20μm |

| TR 5508/1000 | 0~1000μm | 50μm |

| TR 5508/2000 | 0~2000μm | 100μm |

- 1JJF 1484-2014《Calibration Specification for Wet Film Thickness Gauges》

- 2CB/T 3718-2016《Inspection requirement of coating film thickness for ship》

- 3ISO 2808-2019《Paints And Varnishes - Determination Of Film Thickness》

- 4ASTM D4414-95-2020《Standard practice for Wet Film Comb measurement of wet film thickness》

- 5ASTM D1212-2020《Standard test method for wet film thickness measurement of organic coatings》

- 6ISO 2808-2007《Paints and varnishes - Determination of film thickness》

- 7GB/T 13452.2-2008《Paints and varnishes - Determination of film thickness》

TR 5508 / 2000

TR 5508 / 2000