OSP-100 L1875mm φ 16mm custom wire rod/Metering rod

SEOSP OSP-100 L1875 Φ16 Formed wire coating barSPEC

OSP OSP-100 L1875 Φ16 Formed wire coating barDetails

OSP OSP-100 L1875 Φ16 Formed wire coating barPacking list

- SKU

- NB004341

- WFT

- 100μm

- Main rod diameter

- 16mm

- Effective application width

- 1875mm

- clamping length at both ends

- without

- Total length

- 1875mm

- material

- 304 stainless steel

Parameters

| name of article | Model | Wet film thickness | diameter | Coating width | Hand grip part | Overall length |

| Custom extruded wire rods | OSP-42 | 42µm | 16mm | 1875mm | not | 1875mm |

| OSP-64 | 64um | |||||

| OSP-80 | 80um | |||||

| OSP-100 | 100um |

OSP coating Film Applicator multi-angle real shooting

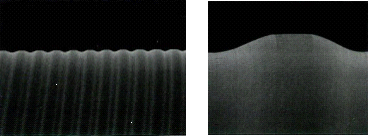

Stainless steel scraper compared to traditional threaded scraper

The traditional thread scraper is coated by winding a thin steel wire on the surface of the steel rod, and the thin steel wire on the surface is easy to loosen and break, and it is not easy to clean, and it cannot be coated with ultra-thin film.

Deficiencies of traditional Film Applicators:

★ The steel wire is easy to loosen and break

★ Not easy to clean

★ Ultra-thin film coating is not possible

Is there a product that can replace the wire scraper?

After several improvements, OSP finally succeeded in developing the D-BAR. It was officially launched into the market in 2001.

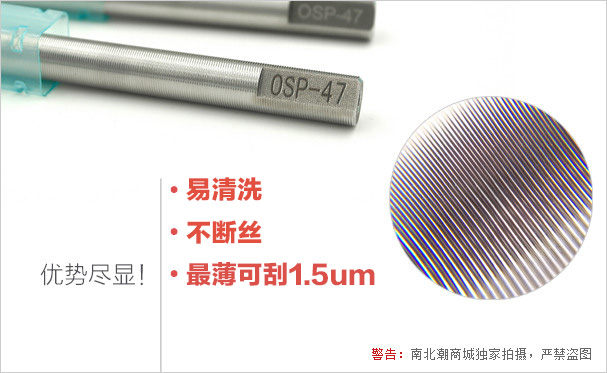

Advantages of stainless steel scraper:

In order to solve the above problems, OSP has developed a new extruded Film Applicator. The stainless steel scraper uses a precision mold and uses cold extrusion technology to process a concave and convex wavy curve on the surface of the steel bar, which has the same coating effect as the traditional wire Bar Coater. However, because there is no thin steel wire wound on its surface, there is no worry about the steel wire loosening and breaking. Moreover, the curved lubrication of the surface is smooth, making it very easy to clean. The most commendable thing is that the stainless steel scraper breaks through the limit of the traditional wire rod coater, and can coat the wet film with a thickness of only 2um, which solves the problem of ultra-thin film coating in one fell swoop.

★ There is no worry about the wire being loose and broken

★ Very easy to clean

★ Ultra-thin film coating is possible

It won't come loose, it won't break

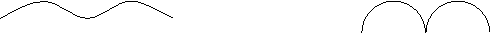

The principle of plastic deformation of metal is used to roll various mountain shapes on the surface of the steel rod.

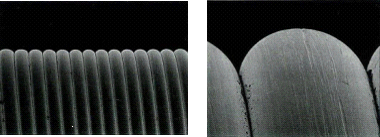

Comparison of cleaning results:

OSP Extruded Wire Rod Filmmaker Traditional filament wound wire rod applicator

◎Coating solution: Water-based synthetic resin paint

◎ Cleaning method: Soak in alcohol for 24 hours, and then wipe with a cloth.

An easy-to-clean, non-clogging surface shape

![]()

Stainless steel scraper Wire scraper

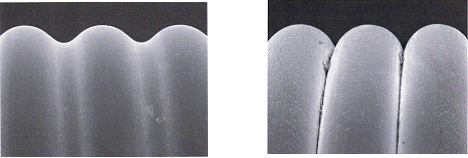

You can choose a good mountain type according to the substrate and coating solution

Standard mountain type (S type)

Standard mountain type (S type)

It has unimaginable performance of Steel Wire Drawdown Rod

It can solve various problems in coating processing

A combination of left and right spiral directions

Prevent the mixing of air bubbles and reduce the loss of substrate caused by air bubble mixing.

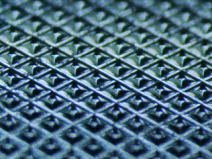

Square eye lines

Mainly used in calendering rollers

It can solve various problems in coating processing

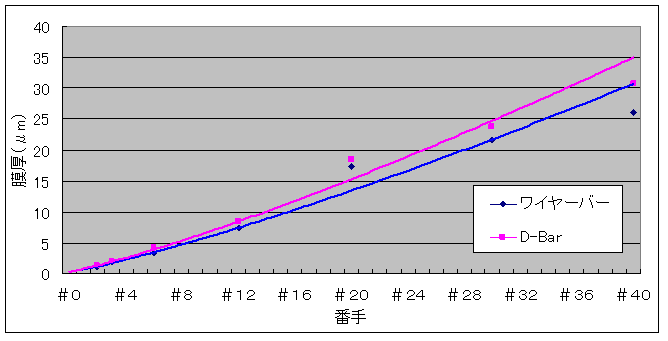

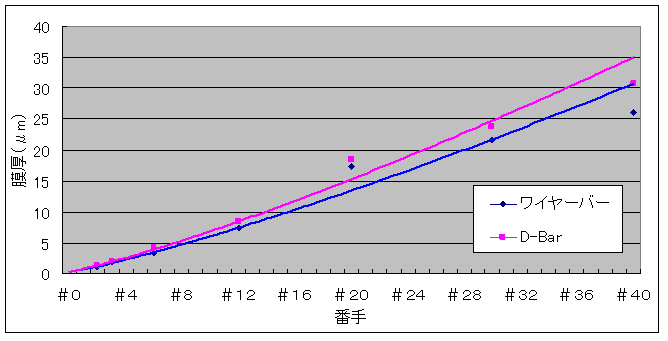

Coating weight comparison:

Difference in coating weight: The bottom of the D-Bar mountain type is wider than that of a conventional Steel Wire Drawdown Rod, so in general, the coating weight of the D-Bar is larger.

Stainless steel scraper model:

| Product number | Maximum wet film thickness |

| OSP-00 | 0um |

| OSP-1.5 | 1.5um |

| OSP-02 | 2um |

| OSP-03 | 3um |

| OSP-04 | 4um |

| OSP-05 | 5um |

| OSP-06 | 6um |

| OSP-07 | 7um |

| OSP-08 | 8um |

| OSP-09 | 9um |

| OSP-10 | 10um |

| OSP-12 | 12um |

| OSP-13 | 13um |

| OSP-15 | 15um |

| OSP-17 | 17um |

| OSP-18 | 18um |

| OSP-22 | 22um |

| OSP-25 | 25um |

| OSP-30 | 30um |

| OSP-35 | 35um |

| OSP-40 | 40um |

| OSP-42 | 42um |

| OSP-47 | 47um |

| OSP-50 | 50um |

| OSP-52 | 52um |

| OSP-60 | 60um |

| OSP-80 | 80um |

| OSP-100 | 100um |

| OSP-120 | 120um |

| OSP-150 | 150um |

Stainless steel scraper selection comparison table

| Wire rod diameter(mm) | OSP model | Tooth profile P=mm H=μm | Volume: mm² |

| 0.02538 | OSP-1.5 | P0.08H4S | 0.002723 |

| 0.02540 | OSP-02 | P0.08H5S | 0.002725 |

| 0.05080 | OSP-03 | P0.1H9S | 0.005451 |

| 0.05082 | OSP-04 | P0.1H10S | 0.005461 |

| 0.07620 | OSP-05 | P0.1H12S | 0.008176 |

| 0.07626 | OSP-06 | P0.1H15S | 0.008183 |

| 0.07631 | OSP-07 | P0.1H17S | 0.008187 |

| 0.10160 | OSP-08 | P0.1H18S | 0.010902 |

| 0.10164 | OSP-09 | P0.1H20S | 0.010908 |

| 0.12700 | OSP-10 | P0.2H21S | 0.013627 |

| 0.12706 | OSP-12 | P0.2H24S | 0.013634 |

| 0.15240 | OSP-13 | P0.2H28S | 0.016353 |

| 0.15255 | OSP-15 | P0.2H34S | 0.016365 |

| 0.17780 | OSP-17 | P0.2H42S | 0.019078 |

| 0.20320 | OSP-18 | P0.25H35S | 0.021804 |

| 0.22860 | OSP-22 | P0.363H49S | 0.024529 |

| 0.25400 | OSP-25 | P0.25H50S | 0.027254 |

| 0.30480 | OSP-30 | P0.363H63S | 0.032705 |

| 0.35560 | OSP-35 | P0.4H75S | 0.038158 |

| 0.35574 | OSP-40 | P0.35H82S | 0.038172 |

| 0.40640 | OSP-42 | P0.4H84S | 0.043607 |

| 0.45720 | OSP-47 | P0.5H95S | 0.049058 |

| 0.48260 | OSP-50 | P0.45H97S | 0.051783 |

| 0.50800 | OSP-52 | P0.5H113S | 0.054509 |

| 0.76200 | OSP-80 | P0.8H167S | 0.081763 |

| 0.93980 | OSP-100 | P1.0H198S | 0.100841 |

| 1.16840 | OSP-120 | P1.2H252S | 0.12537 |

| 1.39700 | OSP-150 | P1.5H300S | 0.149899 |

【Note】The product pictures are for reference only, please refer to the actual product for the appearance of the corresponding OSP scraper rod number