LEEB 934-1 Pasteur Hardness Gauge Soft aluminium and aluminium alloys

SE-

Pap Hardness Gauge BA-2 Hypertherm, Pap Hardness Tester$ 862.00SE

Pap Hardness Gauge BA-2 Hypertherm, Pap Hardness Tester$ 862.00SE -

Pap Hardness Gauge BA-1 Hypertherm, Pap Hardness Tester$ 613.00SE

Pap Hardness Gauge BA-1 Hypertherm, Pap Hardness Tester$ 613.00SE -

TQC VF6500 GYZJ-934-1 Pap Hardness Tester$ 2996.00SE

TQC VF6500 GYZJ-934-1 Pap Hardness Tester$ 2996.00SE -

LANDTEK HM-934-1 + Pasteur Hardness Gauge$ 698.00SE

LANDTEK HM-934-1 + Pasteur Hardness Gauge$ 698.00SE -

Defelsko PosiTector BHI3 Pap Hardness Tester (Premium)$ 2143.00SE

Defelsko PosiTector BHI3 Pap Hardness Tester (Premium)$ 2143.00SE

Leeb 934-1 Pasteur Hardness GaugeSPEC

Leeb 934-1 Pasteur Hardness GaugeDetails

Leeb 934-1 Pasteur Hardness GaugePacking list

- SKU

- NB043778

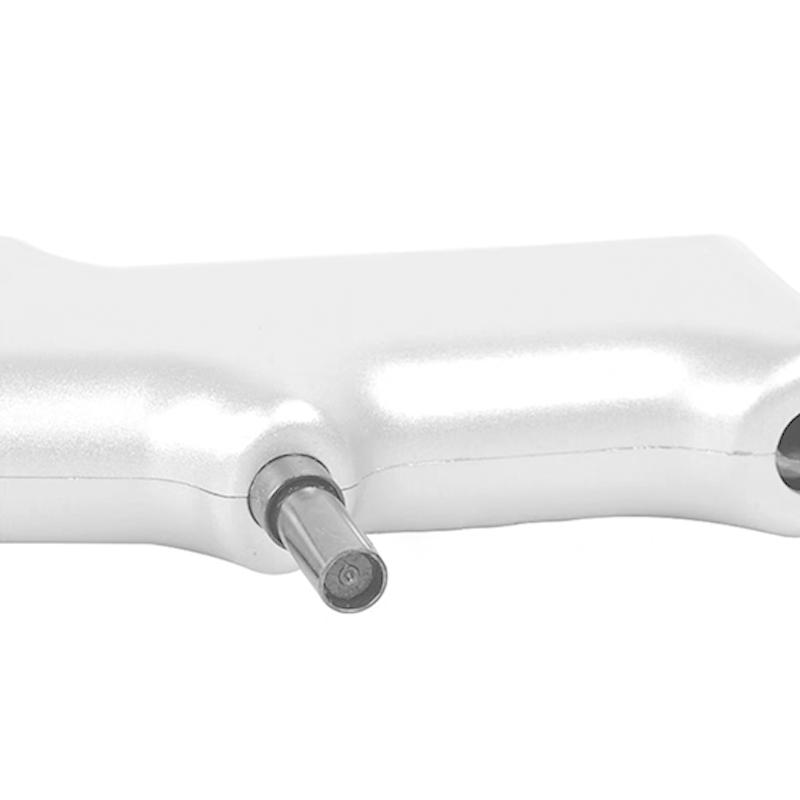

- crimping needle

- 26 ° frusto cone, end face diameter 0.157mm

- range

- 0~100HBa, equivalent to 25~ 135HBW

- Resolution

- 0.5HBa

- Error of indication

- Hardness range 42~ 52HBa +/- 2HBa; hardness range 84~ 88HBa +/- 1HBa

- Repeatability Error

- Hardness range 42~ 52HBa +/- 2HBa; hardness range 84~ 88HBa +/- 1HBa

- Weight

- 0.5kg

Overview

The Pap Hardness Tester is mainly used to test aluminum and aluminum alloys. The Webster Hardness Tester is mainly used to test aluminum alloy profiles, plates and pipes. The Pap Hardness Tester should be used to test pure aluminum, softer aluminum alloys, ultra-thick aluminum alloys, aluminum alloy bars and assembled aluminum alloy products (such as aluminum alloy doors and windows, fire ladders, etc.), and is also used to test glass fiber reinforced plastics (glass fiber reinforced plastics), hard plastics, etc. The improved version of the Pap Hardness Tester can be used for softer plastics, very soft metals, leather, rubber, etc.

Main function

A lightweight indentation Hardness Tester;

Through anodizing treatment, wear-resistant and rust-free, comfortable feel;

Calibration at any time, one-handed operation, no experience required, in any occasion, as long as it is within reach, it can be tested;

Wide measurement range, measurable thickness as low as 1mm, from very soft pure aluminum to particularly hard aluminum alloy can be tested, the effective measurement range is equivalent to Brinell hardness 25~ 135HBW;

Wide range of applications;

High sensitivity. The instrument has 100 scales, and the sensitivity is much higher than that of the Webster Hardness Tester commonly used in the aluminum alloy industry;

No support required. It can be tested by touching only one side of the sample, without moving or supporting the sample, and is suitable for oversized and ultra-thick workpieces and assemblies;

Conversion is convenient. The hardness values of Brinell, Rockwell, Vickers, and Wechsler can be obtained through the conversion table;

Applicable materials

Aluminum and aluminum alloys, copper and copper alloys, glass fiber reinforced plastic, hard plastics, etc. Its improved version can be used to test ultra-soft metals such as lead and tin and soft plastics, rubber, felt, leather, etc

Relevant standards

Comply with Chinese standard GB/T3854-2005, American standard ASTM B648-2000

GB/T3854-2005 "Reinforced Plastics Bacol Hardness Test Method"

ASTM B648 "Buckle Hardness Tester Test Method for Measuring Hardness of Aluminum Alloys"

ASTM D2583-07 "Test Method for Measuring the Indentation Hardness of Hard Plastics by Pap Hardness Tester"

934-1

934-1