LEEB180D integrated Leeb Hardness Tester for aerial work

SELeeb leeb180D Leeb Hardness TesterSPEC

Leeb leeb180D Leeb Hardness TesterDetails

Leeb leeb180D Leeb Hardness TesterPacking list

- SKU

- NB043835

- Measurement range

- 150-960(HLD)、17.1-68.5(HRC)、77-651(HB)、83-976(HV)、26.4-99.5(HS)、59.6-99.6(HRB)

- Measurement direction

- 360°

- Hardness system

- HL、HB、HRC、HRB、HV、HS

- Storage function

- 600 groups

- Power

- Lithium battery charging 3.7v/300mA

- Dimensions

- 150×40×45mm

- Weight

- 110g

- optional

- Standard test block, communication software

Overview

Ribori Hardness Tester leeb180D uses full Chinese display, menu-based operation, simple and convenient operation. This machine can directly display the hardness values of Richter, Brinell, Rockwell, Vickers, Shore and so on. The high-brightness LED backlight is convenient for use in dark environments, and has power-saving functions such as automatic sleep and automatic shutdown, and low-power consumption design. Lithium battery supply, suitable for on-site field operations. The instrument is compact and pocket-type in the palm of your hand, which is easy to carry and has high test accuracy.

Features

According to the Leeb hardness measurement principle, the Leeb measurement interface is displayed at start-up.

Menu-based, informative and intuitive.

The high-brightness LED backlight is convenient for use in low-light environments.

Power-saving functions such as auto-sleep and auto-shutdown, low-power design.

Lithium battery charging, can last up to 10 hours.

Applicable Materials

Steel & Cast Steel, Alloy Tool Steel, Stainless Steel, Grey Cast Iron, Ductile Iron, Cast Aluminium Alloy, Copper-Zinc Alloy (Brass), Copper-Tin Alloy (Bronze), Pure Copper, Forged Steel.

Applications

1. Installed mechanical or permanent assembly parts

2. Mold cavity, heavy workpiece

3. Failure analysis of pressure vessels, steam turbine generator sets and their equipment

4. Measure workpieces, bearings and other parts with very narrow space

5. Material differentiation of metal material warehouse, inspection of multiple measurement parts in a large range of large workpieces

6. When testing the hardness of the bearing, it is necessary to pay attention to the bearing diameter, if the diameter is too small, you need to choose a special-shaped support ring

The Leeb Hardness Tester meets the standard

1. GB/T 17394.1-2014 "Hardness test on metallic materials – Part 1: Test methods"

2. GB/T 17394.2-2012 "Hardness test on metal materials – Part 2: Inspection and calibration of Hardness Tester"

3. GB/T 17394.3-2012 "Hardness test on metal materials – Part 4: Calibration of standard hardness blocks"

4. GB/T 17394.4-2014 "Hardness test on metallic materials – Part 4: Standard value conversion table"

5. The design is based on the standard: "Technical Conditions for Leeb Hardness Tester" JB/T 9378-2001

Requirements for the surface of the test specimen

The condition of the specimen surface should meet the relevant requirements in the test scope table.

The surface temperature of the sample should not be too high and should be less than 120°C.

The surface roughness of the specimen should not be too large, otherwise it will cause measurement errors. The surface of the specimen is exposed to metallic luster, and is flat, smooth, and free of oil.

Specimen weight requirements: for heavy specimens greater than 5kg, no support is required, and specimens weighing 2-5kg, specimens with overhangs and thin-walled specimens should be supported by objects during testing to avoid deformation, deformation and movement of specimens caused by impact. For medium-sized specimens, place them on a flat, firm plane, and the specimen is placed smoothly without shaking.

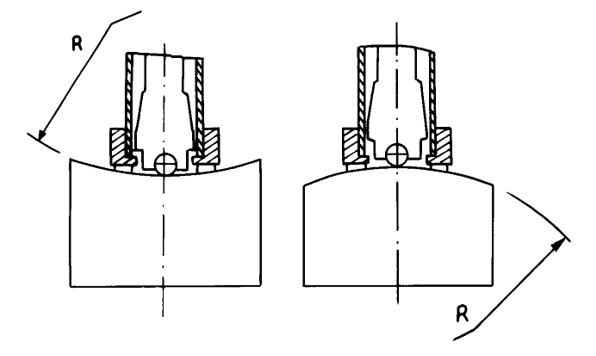

Curved sample: The test surface of the specimen is flat. When the radius of curvature R of the measured surface is less than 30mm (D, DC, C, DL type impact device) and less than 50mm (G type impact device), small support rings or special-shaped support rings should be used for testing.

The specimen should have the corresponding thickness, and the small thickness of the specimen should conform to the provisions of the impact device table.

For specimens with a case-hardened layer, the depth of the hardened layer should be in accordance with the table of impact devices.

coupling

1) For light specimens, it needs to be tightly coupled with a strong supporting body, the two coupling surfaces need to be flat and smooth, the amount of couplant should not be too much, and the test direction should be perpendicular to the coupling plane;

2) When the specimen is a large-area plate, long rod or bent piece, even if the weight and thickness are large, it may still cause deformation and instability of the specimen, resulting in inaccurate test values, so it should be firmly fixed or supported on the back of the test point.

The specimen itself should be less than 30 gauss.

- 1DL/T 1845-2018《Test method for Leeb hardness of high-alloy steels in power equipment》

- 2GB/T 13313-2008《Methods of shore and leeb hardness testing for rolls》

- 3GB/T 17394.1-2014《Metallic materials―Leeb hardness test―Part 1: Test method》

- 4GB/T 17394.4-2014《Metallic materials―Leeb hardness test―Part 4:Tables of hardness values conversation》

- 5GB/T 17394.3-2022《Metallic materials—Leeb hardness test—Part 3: Calibration of reference test blocks》

- 6GB/T 17394.2-2022《Metallic materials—Leeb hardness test—Part 2: Verification and calibration of hardness testers》

- 7GB/T 17394-1998《Metallic materials--Leeb hardness test》

- 8GB/T 17394.3-2012《Metallic materials - Leeb hardness test - Part 3: Calibration of reference blocks》

- 9GB/T 17394.2-2012《Metallic materials - Leeb hardness test - Part 2: Verification and calibration of hardness testers》

- 10JB/T 9378-2001《Leeb hardness testers》

leeb180D

leeb180D