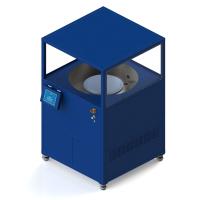

CHINA 12E spin coating machine, touch screen, test spin coating machine

SEHuiNuo 12E Glue levelerSPEC

HuiNuo 12E Glue levelerDetails

HuiNuo 12E Glue levelerPacking list

- SKU

- NB043959

- Power

- AC180-250V, single phase

- Power supply power

- 200W

- loading diameter

- Select 10/20/30... 100mm, choose two

- program group

- Segments 1-5 (edit pages), 12 groups

- Every time

- 3000S, resolution 0.1S

- speed range

- 100-10000RPM, resolution 1RPM

- Acceleration

- 100-10000RPM/S No load

- Weight

- 11kg

- Accessories

- Vacuum pump

- Vacuum input requirements

- 0.06-0. 09MPa, Vacuum Flow rate Minimum 15 L/Min or more

- Vacuum interface

- Comes with 6mm tube 1 meter

Introduction

A glue spreader is a device used to coat films, glue solutions or other liquid materials on the surface of a substrate. Its Principle is based on centrifugal force. Spinning machines have important applications in semiconductor manufacturing, optical coatings, materials science and other fields, especially in processes such as preparing thin films and coating photoresist. The process parameters of the Spin Coater include rotation speed, rotation time, glue viscosity, dripping position, etc. These parameters influence the thickness, uniformity and quality of the coating. Different applications and materials may require different process parameters.

The Spin Coater includes single-head, multi-head, single-speed, multi-speed and other series of products to meet the different needs of customers. The Spin Coater is mainly used for photoresist coating, boron coating and other processes.

The 12E spin coating and leveling machine is controlled by a touch screen and uses advanced motors and drivers. The suction piece uses a solenoid valve to control the air path. The leveling time is 3000s, the rotation speed is 100-10000, and the acceleration is 100-10000.

Advantages

This equipment has the characteristics of high glue uniformity efficiency and easy use.

The glue uniformity speed and time are divided into multiple periods and are steplessly adjustable.

The electrical circuit is reliable and the motor runs smoothly, especially the motor has large torque, which is better than similar products.

The suction piece uses a solenoid valve to control the air path, which is suitable for assembly line processes. One air pump can work with several Spin Coaters at the same time, improving efficiency.

Features

Coating uniformity: The glue spreader can evenly coat the glue on the surface of the substrate through the action of centrifugal force to achieve a high-quality film or coating. This uniformity is of critical importance for many applications, such as photolithography processes.

Process controllability: Spinning machines usually provide a wealth of parameter adjustment options, such as rotation speed, rotation time, coating position, etc. Operators can adjust these parameters according to specific needs to achieve the desired coating effect and film thickness.

Wide range of applications: The glue spreader is not only suitable for coating photoresist, but can also be used for coating other types of glue, liquid materials or solutions, such as polymer coatings, film preparation and other fields.

Rotation speed range: The rotation speed of the Spin Coater usually has a wide range and can be adjusted from low speed to high speed to meet the needs of different coating thickness and uniformity.

Vacuum adsorption: In order to ensure that the substrate remains stable during the spin coating process, the Spin Coater is usually equipped with a vacuum adsorption system to ensure that the substrate is firmly fixed on the tray.

Automatic control: Many glue dispensers provide automatic control options that can preset coating parameters through programming, thereby automating the coating process.

Principle

The Principle of the Spin Coater is to drop glue liquid on the rotating substrate, and then use the rotating motion to evenly distribute the glue liquid on the surface of the substrate to form a thin film or coating. Centrifugal force will spread the glue from the center to the outer edges, eventually forming a uniform coating. Parameters such as the rotation speed and time of the Spin Coater and the viscosity of the glue will affect the thickness and uniformity of the film or coating.

12E

12E