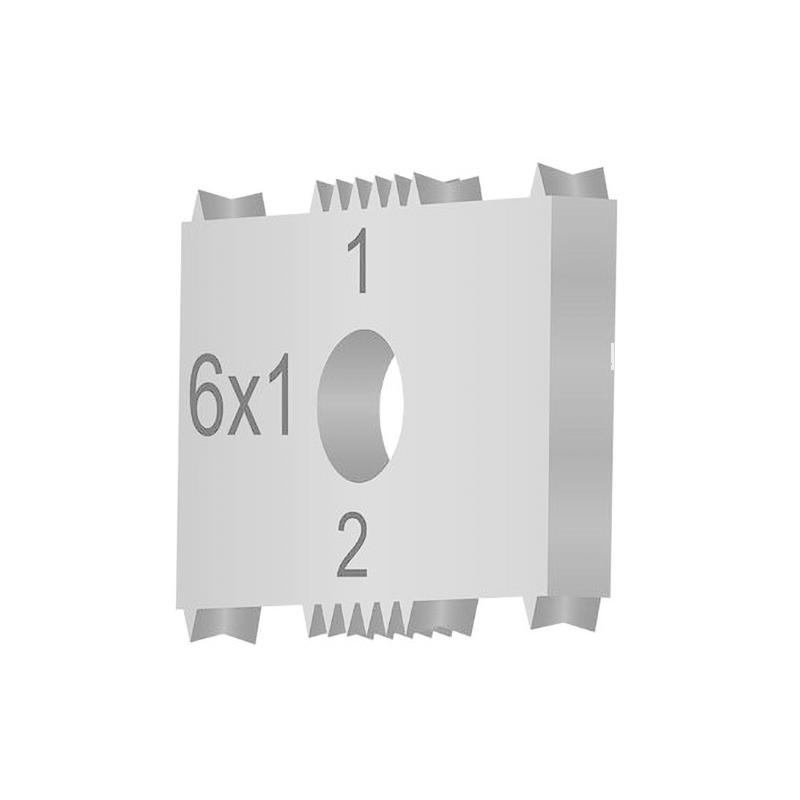

Defelsko PosiTest CH Cross-cut Adhesion Tester Set ISO2409 23mm/6 Teeth

-

QFH Cross Hatch Cutter 1/2/3 mm Tooth QFH Cross Hatch Cutter 6 Tooth$ 188.00SE

QFH Cross Hatch Cutter 1/2/3 mm Tooth QFH Cross Hatch Cutter 6 Tooth$ 188.00SE -

TRUIT TR 5001/5 Single Face Cross Hatch Cutter 3mm/6 Teeth$ 146.00SE

TRUIT TR 5001/5 Single Face Cross Hatch Cutter 3mm/6 Teeth$ 146.00SE -

PUSHEN HGQ 3 * 5 Cross Hatch Cutter Number of teeth 6 teeth, pitch 3mm$ 181.00SE

PUSHEN HGQ 3 * 5 Cross Hatch Cutter Number of teeth 6 teeth, pitch 3mm$ 181.00SE -

TQC SP1704 cross-cut cutter head 6 teeth, spacing 3mm for CC2000/CC3000 series$ 368.00SE

TQC SP1704 cross-cut cutter head 6 teeth, spacing 3mm for CC2000/CC3000 series$ 368.00SE -

QFH-A cross-cut adhesion Tester YONGLIDA standard 3 swirl/spin cutter heads$ 178.00SE

QFH-A cross-cut adhesion Tester YONGLIDA standard 3 swirl/spin cutter heads$ 178.00SE

Defelsko CHKITISO6X3 Cross-cut Adhesion TesterSPEC

Defelsko CHKITISO6X3 Cross-cut Adhesion TesterDetails

Defelsko CHKITISO6X3 Cross-cut Adhesion TesterPacking list

- SKU

- NB044008

- Number of teeth

- 6 teeth

- Tooth spacing

- 2mm

- Applicable film thickness environment

- 121~250μm

- Cutter head material

- Harden just

- Application standard

- ISO 2409

Introduction

Cross-scratch adhesion TesterAccording to ISO 2409 and ASTM D3359, the ability of the coating to resist separation from the substrate is determined when cutting a lattice pattern on the coating.

All tools and accessories needed to perform the cross-scratch test are included.Ergonomically designed tool grip with non-slip grip for comfortable all-day use.The rotatable cutting head ensures proper positioning and uniform cutting surface pressure.Easy-to-change, hardened steel blade with 4 cutting edges for longer testing.Tapes are available in accordance with ISO 2409 or ASTM D3359.

peculiarity

Includes all tools and accessories required for cross-scratch testing in accordance with ISO 2409 and ASTM D3359

Ergonomically designed tool grip with non-slip grip for comfortable all-day use

The rotatable cutting head ensures proper positioning and uniform cutting surface pressure

Easy to replace, hardened steel blade with 4 cutting edges for longer testing

Suitable for coating thicknesses up to 250 μm (10 mm), depending on the blade and standard

Available in a wide range of 4-in-1 cutting blades with different standards, coating thicknesses and substrates, the tool is compatible with all DeFelsko cutting blades

Illuminated magnifiers with 3x or 10x magnification are available according to the standard

A brush is included to remove debris from the coating

Adhesive tapes are available in accordance with ISO 2409 or ASTM D3359

The durable hard-shell case keeps the contents safe

Meets standards

ISO 2409/16276-2, ASTM D3359, AS 3894.9/1580.408.4, JIS K 5600-5-6.

Optional kits

The PosiTest CH Cross Scratch Adhesion Test is available in 5 sets, 3 of which are ISO 2409 compliant and 2 are ASTM D3359 compliant.

Use the table below to select the appropriate blade based on the standard and the thickness of the coating to be tested.

| Coating thickness environment | Blade specifications | Kit model |

| ISO2409 | ||

| 0~60μm | 1mm/6 teeth | CHKITISO6X1 |

| 61~120μm | 2mm/6 teeth | CHKITISO6X2 |

| 121~250μm | 3mm/6 teeth | CHKITISO6X3 |

| *For soft substrates (e.g. wood and plaster), use a 2mm/6-tooth blade when the coating thickness is between 0~120μm. | ||

| ASTM D3359 | ||

| 0~50μm | 1mm/11 teeth | CHKITASTM11X1 |

| 51~125μm | 2mm/6 teeth | CHKITASTM6X2 |

- 1JJF 2163-2024《Calibration Specification for Paint Film Scribers》

- 2SJ 20910A-2018《General specification for powder spraying coating》

- 3GB/T 31586.2-2015《Corrosion protection of steel structures by protective paint systems—Assessment of, and acceptance criteria for, the adhesion/cohesion (fracture strength) of a coating—Part 2: Cross-cut testing and X-cut testing》

- 4GB/T 9286-2021《Paints and varnishes—Cross-cut test》

- 5ISO 2409-2020《Paints and varnishes — Cross-cut test》

- 6ISO 2409-2007《Paints And Varnishes - Cross-Cut Test》

- 7GB/T 9286-1998《Paints and varnishes 一 Determination of density》

- 8ISO 2409-1992《Paints and varnishes cross-cut test》

- 9GB/T 9286-1998《Paints and varnishes cross-cut test》

CHKITISO6X3

CHKITISO6X3