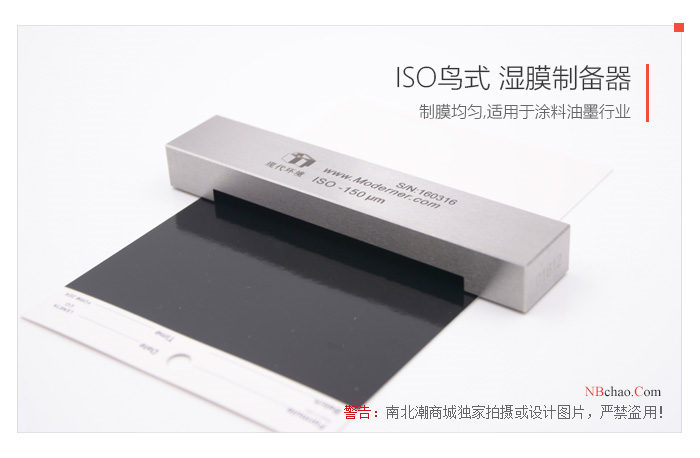

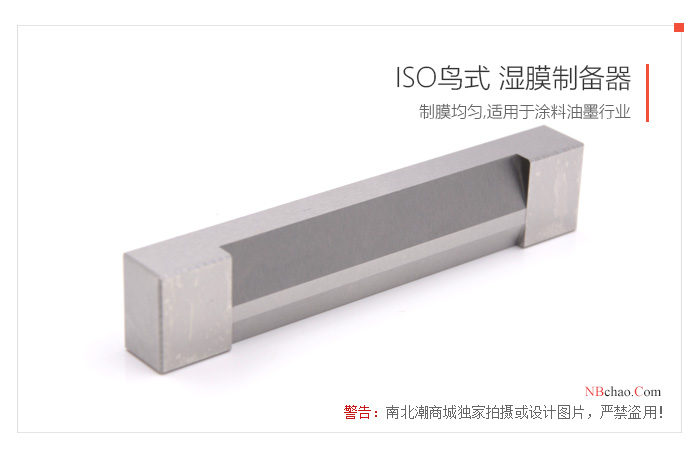

MODERNER SZQ-600 (ISO Bird-type) Stainless Steel Film Applicator 600 micron Film Applicator

SEModerner SZQ-600 (ISO Bird-type) Film ApplicatorSPEC

Moderner SZQ-600 (ISO Bird-type) Film ApplicatorDetails

Moderner SZQ-600 (ISO Bird-type) Film ApplicatorPacking list

- SKU

- NB004425

- type

- Single-sided ISO Bird-type

- WFT

- 600µm

- Application width

- 100mm

- precision

- ± 10µm

- material

- High carbon chromium stainless steel

- standard

- ISO standard

SZQ-600 stainless steel Wet Film Applicator overview

MODERNER stainless steel Wet Film Applicator SZQ-600 has a coating film thickness of 600μm and a groove width of 100mm. The stainless steel Wet Film Applicator is made of high-carbon chromium stainless steel with high hardness. The precision of SZQ-600 stainless steel Wet Film Applicator is ±10μm, which is in line with ISO standard.

Materials used

SZQ-600 (ISO bird type) stainless steel Wet Film Applicator adopts 9Cr18Mo high-carbon chromium stainless steel, and 9Cr18 is high-carbon chromium martensitic stainless bearing steel. It has high hardness and wear resistance, high temperature and low temperature dimensional stability.

Hardness value

The hardness value of SZQ stainless steel Wet Film Applicator is HRC48±2.

Operating procedures

First, place the sample on the platform and fix the sample to ensure that the Wet Film Applicator does not move when it slides over.

Second, according to the required wet film thickness requirements, select a Wet Film Applicator of the corresponding specification, and place it on the short side of the template, close to parallel or at a specified position.

Thirdly, pour about 5 ml of the sample in front of the Wet Film Applicator, press both ends of it with your fingers, and slide at a constant speed of 150 mm/s to finally obtain a wet film with the required thickness.

Fourth, the SZQ-600 (ISO bird type) stainless steel Wet Film Applicator is cleaned and dried with a suitable solvent after use, and the surface is coated with oil or petroleum jelly.

Pictures

- 1YS/T 680-2016《Powder for coating aluminium alloy extruded profiles for architecture》

- 2GB/T 1727-2021《General methods for preparation of coating films》

- 3HG/T 20720-2020《Construction and acceptance specification of waterborne anti-corrosion coatings for steel structures in industrial buildings》

- 4HG/T 3951-2007《Water based colorants for architectural coatings》

- 5GB/T 9755-2014《Synthetic resin emulsion coatings for exterior wall》

- 6ASTM D823-2018《Paints, varnishes and related products of uniform thickness on the test board》

- 7GB 1727-1992《Paint film general preparatory method》

SZQ-600 (ISO Bird-type)

SZQ-600 (ISO Bird-type)