DAQTECH iboo-4 Furnace temperature tracker Linear dispersion Tester, four channel painting furnace temperature tracker

SEDAQTECH iboo-4 Furnace temperature trackerSPEC

DAQTECH iboo-4 Furnace temperature trackerDetails

DAQTECH iboo-4 Furnace temperature trackerPacking list

- SKU

- NB044268

- number of channels

- 4 channel

- Sensors

- Thermocouple K

- maximum temperature

- 1000℃

- Temperature measurement Accuracy

- ±0.5%

- usage time

- 300 degrees for 1 hour, 200 degrees for 2 hours, 300 degrees for 2 hours, 300 degrees for 3 hours, 500 degrees for 1 hour and other specifications, specific requirements can be selected.

- memory

- Each channel can record and store 16,000 pieces of data

- Sampling rate

- 1S, 2s, 3s, 4s, 5s, 6s, 10s, 20s, 30s, 1min, etc., can be selected by the user.

- Computer requirements

- Windows 98, 2000, XP, etc., can print out the temperature Linear dispersion through the computer.

- Setup software

- A) The sampling period is optional b) Start/stop recording is convenient

- analysis software

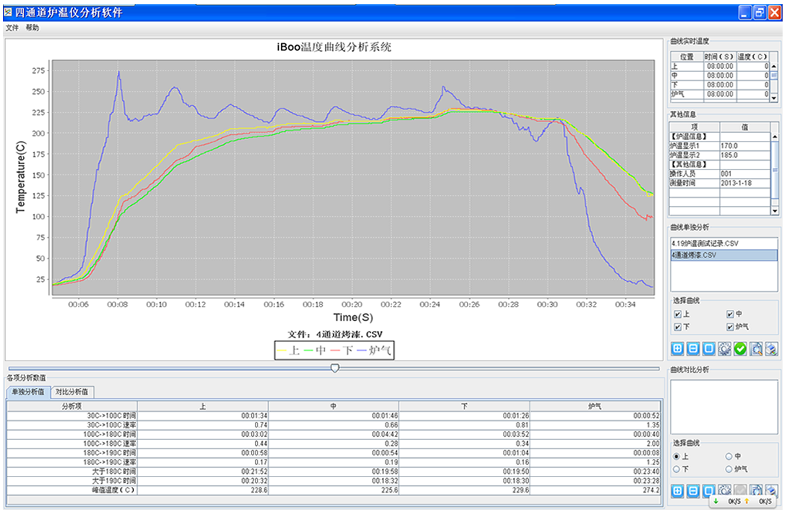

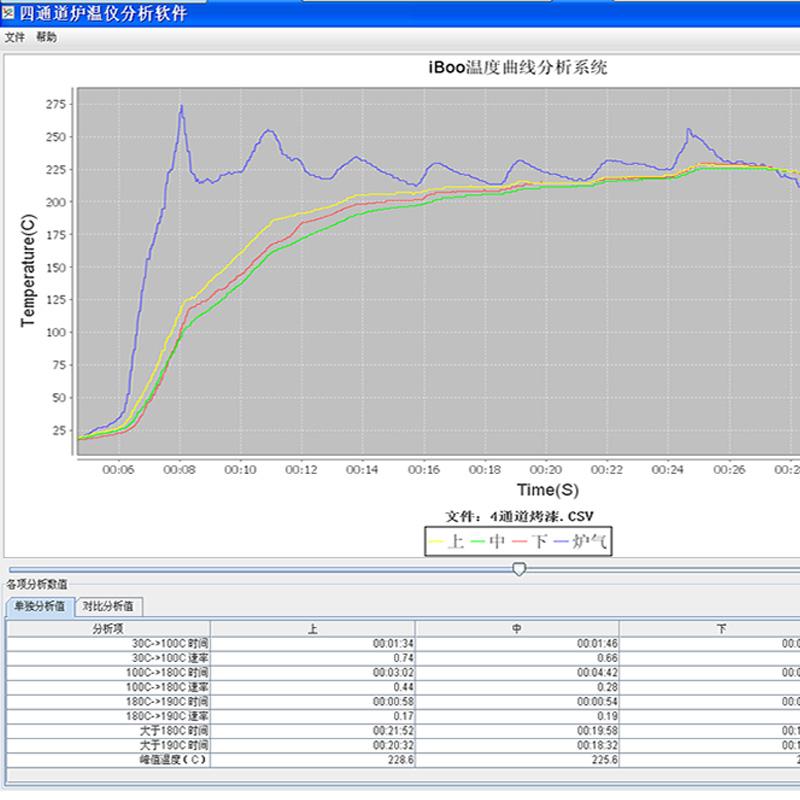

- A) Each Linear dispersion can be displayed or not; b) the Heating rate between any two temperatures can be calculated; c) the time above a certain 4 temperatures can be calculated; d) the peak temperature can be calculated; e) the test data can be compared 2-5 times

- incubator size

- 11*13*32mm

- Insulation box

- Not included, need to be purchased separately

product description

The good thermal insulation performance of the furnace temperature tracker enables the test system to perform temperature mapping in harsh thermal environments. Passing through the heat treatment furnace together with the product, the temperature of the heat treatment furnace and the product can be tracked and monitored throughout the process. Valuable data can be obtained without dragging the coupling test. The curve analysis report formed can instantly provide engineers with the true temperature status of the product and furnace, which will tell How do you optimize operations. By balancing temperature, time and heating rate, you can increase line speed and product quality, achieving high-efficiency production.

The furnace temperature tracker is a high-precision, high-stability furnace temperature test and recording product. The system is also equipped with a powerful software analysis system to save the collected temperature values, and the host computer software analysis system analyzes the functional temperature Synchronous analysis and processing of parameters such as length, time, product function, etc.

Application

Painting, non-stick coating, steel heat treatment, hub heat treatment, SMT, brazing, automobile painting, food baking, ceramic firing, enamel.

Features

iBoo-T4 is original and authentic from Taiwan, CHINA, quality guaranteed.

The large screen display makes the temperature display more intuitive.

Thermocouples can be directly inserted for real-time temperature testing.

The temperature value is displayed directly.

Data recording can be performed and the collected data can be sent to the computer for data analysis.

The adoption period can be changed (minimum 1 second).

Built-in clock, can change internal time and synchronize computer time.

iboo-4

iboo-4