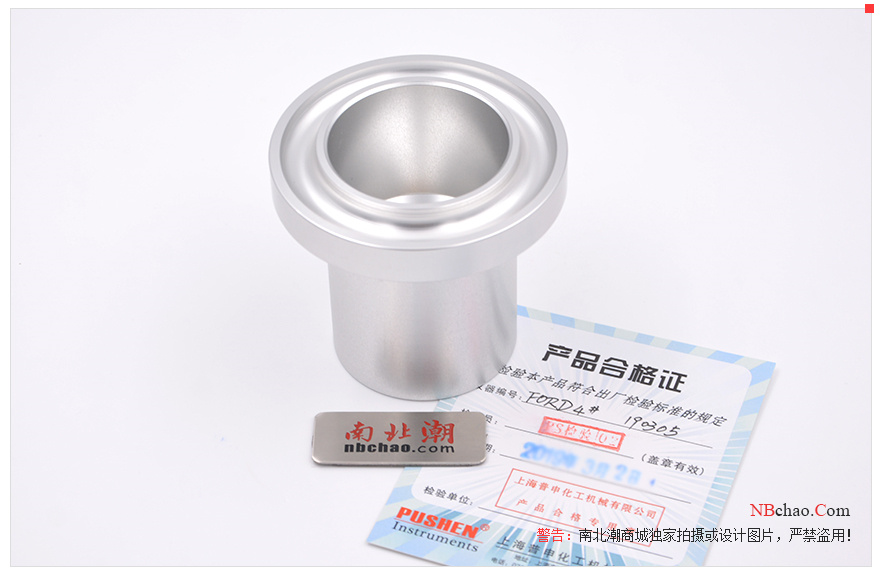

Pushen Ford-1 #cup with bracket, aluminum material

SEPushen Ford-1# Ford cup with bracketSPEC

Pushen Ford-1# Ford cup with bracketDetails

Pushen Ford-1# Ford cup with bracketPacking list

- SKU

- NB000444

- Viscosity range

- 10~35cSt

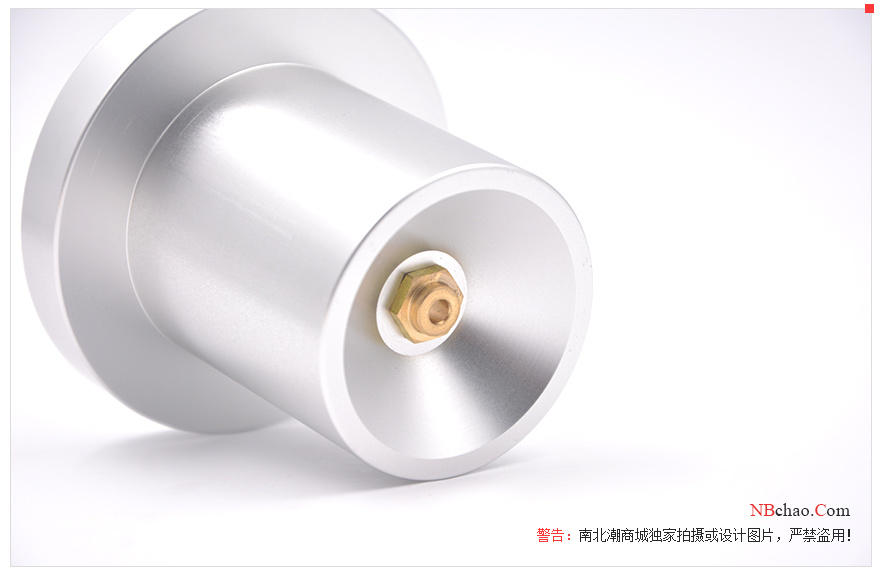

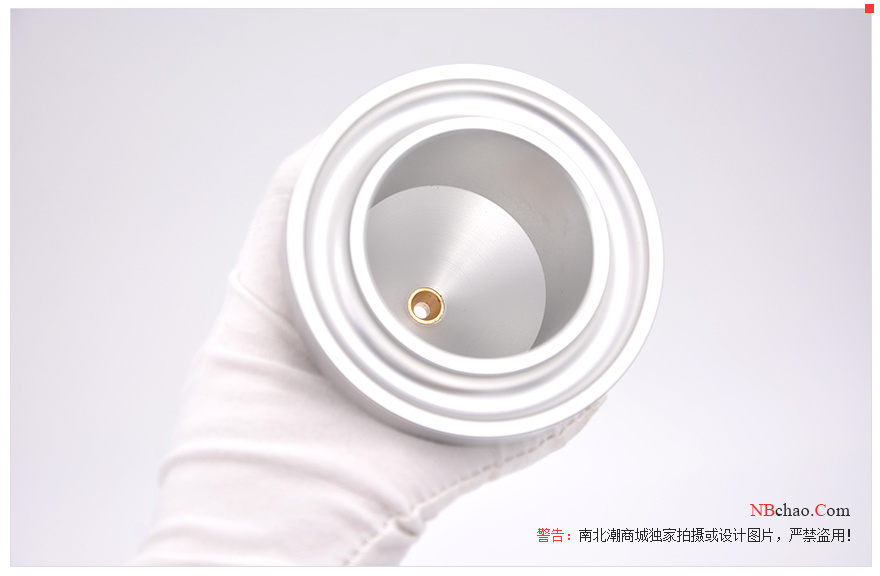

- Flow hole diameter

- 1.9mm

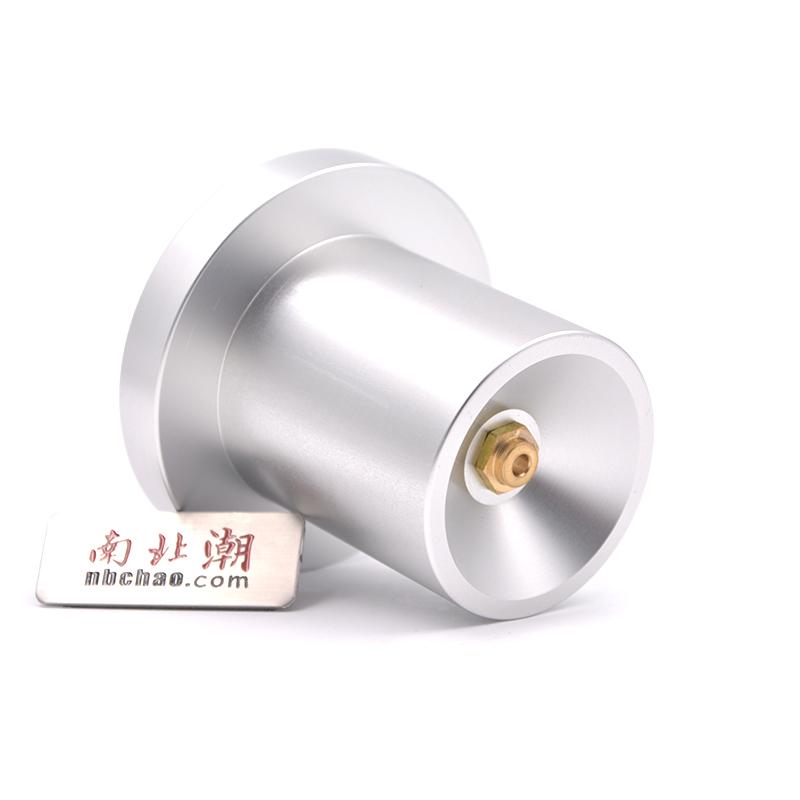

- Capacity

- 100ml

- Cup height

- 87mm

- Cup width

- 55mm

- Cup body material

- Aluminum cathode oxidation

- Filter material

- Brass

- Applicable standard

- ASTM D1200

- Environment temperature

- 23±0.2℃

- Weight

- 292g

- bracket

- With bracket

Introduction to Pusheen Ford Cup

Pushen/Pushen Ford Cup (also known as Ford Cup) is produced in accordance with the standard ASTM D 1200 of the American Society for Testing and Materials for paint and raw materials. The cup body of the Ford Cup is made of anodized aluminum, and the outflow hole is made of brass. According to the different diameters of outflow holes, Pushen has designed five models of Ford cups, No. 1, No. 2, No. 3, No. 4, and No. 5, all of which are used to test the viscosity of coatings, paints, etc., and the applicable measurement time is different.

The Ford cup can measure the viscosity of the sample by measuring the time required for a certain volume of the sample in the aluminum cup to flow out of the small hole at the bottom.

The Pushen/Pushen No. 1 Ford Cup is equipped with a stand for easy viscosity testing.

Design advantage

The design of the ring groove at the mouth of the cup can store the spilled liquid.

The external dimensions are designed so that they can be used in conjunction with the Viscosity Cup holder.

Easy to clean. There are no difficult-to-clean recesses in the structure of the cup wall and outflow hole.

Ford Viscosity Cups are produced with consistent quality control.

Each No. 1/2/3/4/5 Ford Cup is engraved with a unique serial number.

Standards

Ford (Ford) cups are made according to ASTM D 1200, the standard for paint and raw materials of the American Society for Testing and Materials

Pictures

- 1ASTM 《Standard Test Method for Viscosity by Ford Viscosity Cup》

- 2ASTM D1200-2010《Standard Test Method for Viscosity by Ford Viscosity Cup》

- 3KS A0531-1993《Viscosity of Liquid - Methods of Measurement》

- 4ASTM D5125-2020《Standard Test Method for Viscosity of Paints and Related Materials by ISO Flow Cups》

- 5JJG 743-2018《Flow Cup Viscometers》

- 6ASTM D1200-2018《Test method for viscosity by Ford viscosity cup》

- 7GB/T 2794-1995《Determination methods for viscosity of adhesives》

- 8 《Determination of viscosity with Ford viscosity cup》

Ford-1#

Ford-1#