CHINA NBC-5637 MIT Paper Folding Endurance Tester

SE

-

JINGWEN JW107C2 paper MIT folding resistance Tester$ 1360.00SE

JINGWEN JW107C2 paper MIT folding resistance Tester$ 1360.00SE -

Yunda YD-NZY MIT flexural strength Tester to detect paper fatigue resistance$ 2013.00SE

Yunda YD-NZY MIT flexural strength Tester to detect paper fatigue resistance$ 2013.00SE -

JINGWEN JW107C MIT Paper Folding Endurance Tester$ 1457.00SE

JINGWEN JW107C MIT Paper Folding Endurance Tester$ 1457.00SE -

CHINA NBC-5632 MIT type folding Tester Paper Folding Endurance Tester$ 1420.00SE

CHINA NBC-5632 MIT type folding Tester Paper Folding Endurance Tester$ 1420.00SE -

CHINA BLD-NZ12 MIT paper Folding Endurance Tester$ 1395.00SE

CHINA BLD-NZ12 MIT paper Folding Endurance Tester$ 1395.00SE

Factory NBC-5637 MIT Folding Endurance TesterSPEC

Factory NBC-5637 MIT Folding Endurance TesterDetails

Factory NBC-5637 MIT Folding Endurance TesterPacking list

- SKU

- NB044574

- Measurement range

- 1~ 60000 times

- folding logarithm

- 0~4.78

- Spring tension

- 4.9~14.7N

- folding angle

- 135±2°

- folding speed

- 175±10CPM

- Folding mouth seam distance

- 0.50Mm, 0.75mm (randomly equipped), 0.25m, 1.00mm

- Power

- AC220V, 50HZ

- Dimensions

- 330*250*400mm

- Mass

- About 37Kg

Introduction

MIT type folding endurance is a new type of instrument developed according to the national standard GB/T 2679.5-1995 (Determination of folding endurance of paper and cardboard). The instrument has various parameter testing, conversion, adjustment, display, memory, and printing included in the standard. It has data processing functions and can directly obtain statistical results of various data. The instrument has compact structure, small size, light weight, full functions, bench-type placement, easy operation and stable performance. It is suitable for measuring the folding resistance of various cardboards.

Standard basis

The parameters and functions of this instrument comply with national standards: GB/T2679.5-1995 Determination of folding endurance of paper and cardboard (MIT folding endurance meter method)

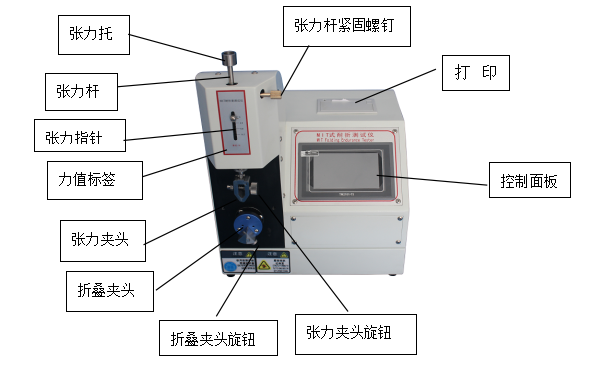

Instrument construction

MIT paper folding endurance Tester has an optical, mechanical and electrical integration structure. The mechanical part includes the motor transmission part and the tension mechanism part. In terms of mechanical transmission, the motor drives the crank slider mechanism to realize the back and forth translation of the rack, and then drives the folding chuck to rotate 135° back and forth through the transmission of the gear and rack. This transmission mechanism is relatively stable in transmission and has been tested in practice for many years and is a relatively reliable transmission method. The tension mechanism deforms the tension spring by pressing down the tension rod, and the resulting spring force exerts force on the tested paper pattern. (The force exerted on the tested paper pattern is adjusted by the deformation produced by the spring.)

The instrument can count the number of double folds of the tested paper sample through the detection of the photoelectric circuit, and can make the motor automatically stop after the sample test is completed. At the same time, the instrument also realizes the automatic return of the folding chuck through the detection of photoelectric circuits.

In addition to parameter setting and measurement display, the electrical part also controls the movement of the entire machine based on the detection of photoelectric circuits. In addition, the experimental data of multiple samples in the same group can be counted: maximum value, minimum value, average value and coefficient of variation, and these statistical data can be printed. The electrical part mainly consists of the motherboard, power board, display panel and printer.

- 1Paper and Cardboard - Determination of folding strength

- 2Folding Tester - paper folding performance test

NBC-5637

NBC-5637