CHINA NBC-8517 Zero Dropping Tester Impact strength Tester

SE

Factory NBC-8517 Zero Dropping TesterSPEC

Factory NBC-8517 Zero Dropping TesterDetails

Factory NBC-8517 Zero Dropping TesterPacking list

- SKU

- NB044583

- test load

- 100Kg, 200kg, 300kg (can be customized)

- drop height

- 0~1000Mm; 0~1500mm; 0~2000mm (can be set)

- Maximum size of specimen

- 1000*1000*1000mm

- Test method

- Face, corner, edge

- Protection device

- The Upper/Lower are equipped with inductive protection devices

- Display mode

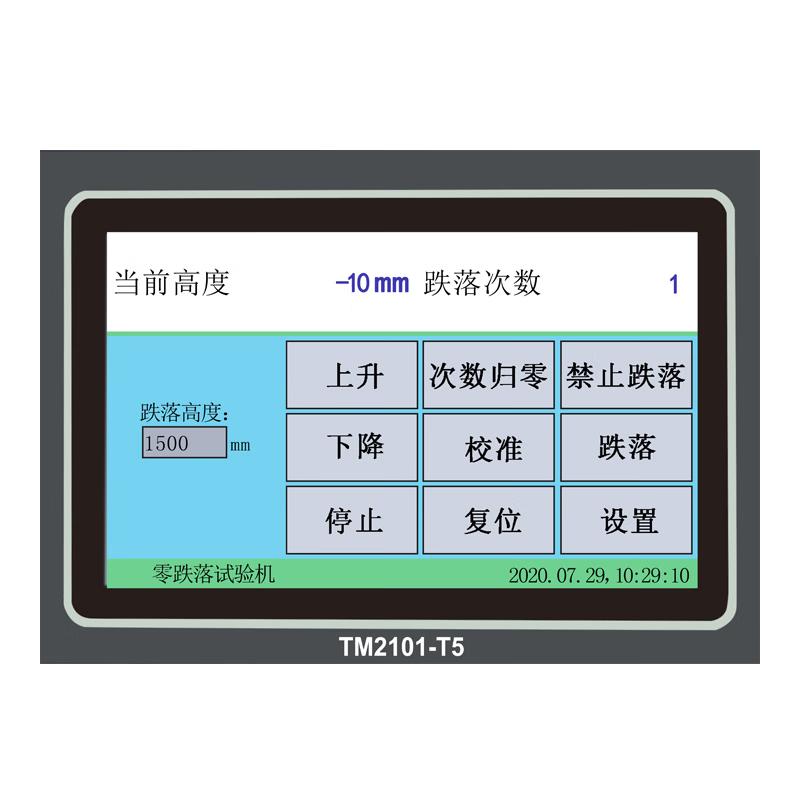

- Touch screen display, height shutdown function can be set

- Bracket structure

- 45 #steel, welded by square pass

- Accelerator

- Pneumatic type (need to be used with air compressor)

- Fall method

- Electromagnetic and pneumatic combination

- Power

- 380V/50Hz

- Weight

- Approx. 800kg

Introduction

For large packaged goods, they generally have a large mass and the vertical drop . Therefore, the test drop height of the drop test bench is also required to be low. The zero drop test machine is mainly used for dropping larger packages. test. The zero-drop testing machine consists of an "E" type that can move downward quickly and serves as a specimen bracket. The tested goods are placed and balanced according to the test requirements (surface, edge, and angle tests). During the test, the pallet moves downward at and separates from the test piece. The "E" type is embedded in the bottom plate under the action of the shock absorber before the packaged goods under test fall to the bottom plate. Theoretically, the zero drop testing machine Drop test can be performed from zero height to the maximum drop height range

The zero-drop testing machine is mainly used to assess the degree of impact of a drop on a package during actual transportation, loading and unloading, and to evaluate the impact strength of the package during transportation and the rationality of the packaging design.

Features

It adopts double-column guide and hydraulic buffer.

The drop height can be set by the fixed ring, which can realize edge and corner drop tests.

It is mainly used to assess the ability of product packages to withstand drops during transportation and loading and unloading, thereby improving and perfecting packaging design.

The zero-drop test bench adopts a plate-type double guide rail guide and an electric lifting system, which is suitable for drop tests on packaging specimens with larger dimensions .

Loading and unloading test pieces is convenient and fast, and can realize lower height , and the drop height can be started from zero.

Control principle

Adopt imported microcomputer electrical rational design to complete the comprehensive design of free fall, edges, corners and surfaces.

Applicable standards

GB/T1019-2008

NBC-8517

NBC-8517