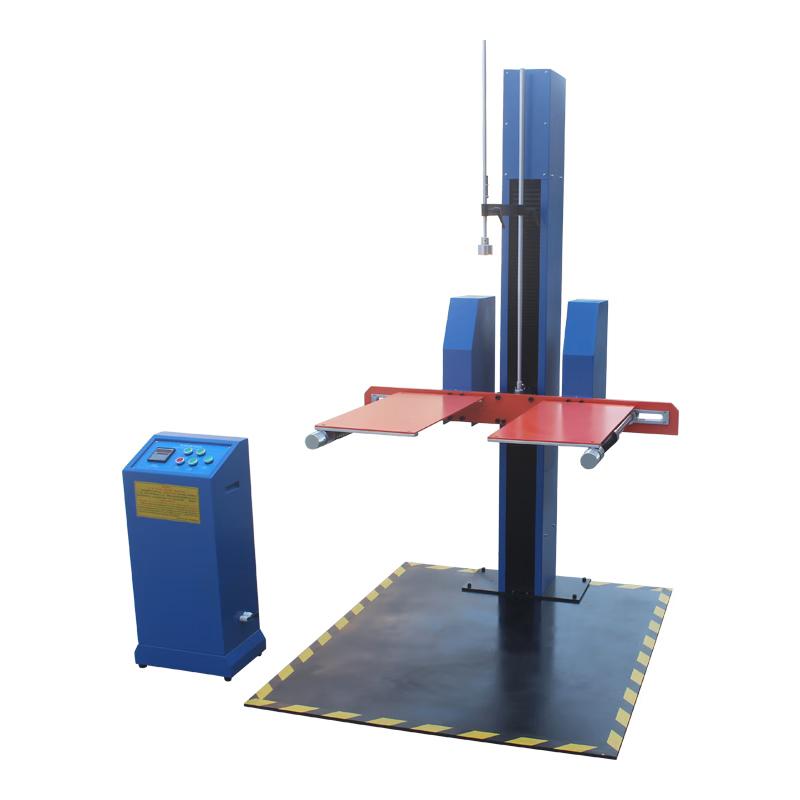

CHINA NBC-8515 wing Dropping Tester

SE

Factory NBC-8515 Double Dropping TesterSPEC

Factory NBC-8515 Double Dropping TesterDetails

Factory NBC-8515 Double Dropping TesterPacking list

- SKU

- NB044585

- drop height

- 400~1500mm

- Maximum Weight of specimen

- 80kg

- Maximum size of specimen

- (L×W×H)1200×800×1000mm

- Drop panel area

- (L×W)1200×1400*10mm

- Arm size

- 300×750×8mm

- drop error

- ±10mm

- Control box size

- (L×W×H)350×350×1100mm

- Machine Weight

- 450Kg Net Weight: 300KG

- Power

- 1∮ ,AC380V,50Hz,10A

- Transmission mode

- Electric drive, manual reset

Introduction

A biplane Drop Tester is a device used to test the durability and safety of products or packaging materials when dropped or impacted. It gets its name from its special design, which usually has two movable "wings" or "arms" used to simulate different directions and angles of the product when dropped. These testing machines are designed to evaluate the structural strength of products, durability and safety of packaging to ensure that products are not damaged or dangerous during transportation, storage or use.

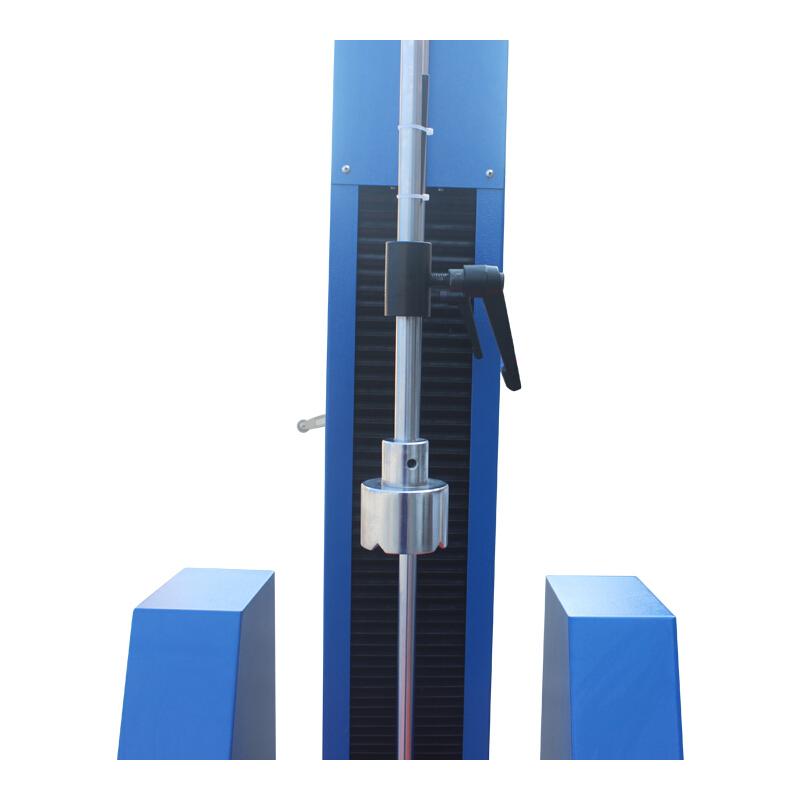

This machine can conduct free drop tests on the surfaces, corners and edges of packages. It is equipped with a digital height display and uses a decoder for height tracking. It can accurately give the product drop height from the surface, and the error will not be different from the preset drop height. More than 2% or 10mm.

Features

This machine adopts a single-arm double-column structure, with automatic reset, electric drop and electric lifting devices, making it easy to use;

The unique hydraulic buffer device greatly improves the service life, stability and safety of the machine.

The single-arm setting makes it easy to place products, and the angle error between the impact surface of the drop angle and the plane of the base plate is less than 50°.

Standards compliant

GB4757.5-84, JB/T 7407-94, ISO2248-1995 "Packaging - Vertical impact and drop test of complete and fully loaded transport packages"

NBC-8515

NBC-8515