CHINA NBC-3009 coefficient of friction Tester, film paper fabric friction test

SE

-

JINGWEN JW120C paper Friction Coefficient Meter range 0-5N$ 1439.00SE

JINGWEN JW120C paper Friction Coefficient Meter range 0-5N$ 1439.00SE -

YD-MCY Friction Coefficient Meter 0.01~ 10N$ 2013.00SE

YD-MCY Friction Coefficient Meter 0.01~ 10N$ 2013.00SE -

CHENCHI MXD-02 Computer Friction Coefficient Meter Range 0-30N$ 2632.00SE

CHENCHI MXD-02 Computer Friction Coefficient Meter Range 0-30N$ 2632.00SE -

CHENCHI MXD-02 Film Friction Coefficient Meter Range 0-10N$ 2632.00SE

CHENCHI MXD-02 Film Friction Coefficient Meter Range 0-10N$ 2632.00SE -

Taichang TC-MXD-02 Touch screen Friction Coefficient Meter 0~5N$ 1497.00SE

Taichang TC-MXD-02 Touch screen Friction Coefficient Meter 0~5N$ 1497.00SE

Factory NBC-3009 Coefficient of frictIon MeterSPEC

Factory NBC-3009 Coefficient of frictIon MeterDetails

Factory NBC-3009 Coefficient of frictIon MeterPacking list

- SKU

- NB044605

- Force range

- 0~5N

- Measurement Accuracy

- 0.001N

- Slider stroke

- 70mm

- Slider Mass

- 200g

- Slider traverse speed

- 1-300mm/min adjustable

- test conditions

- Standard test environment

- Dimensions

- 400*300*200mm

- Power

- AC 220V±10%50Hz

- Net Weight

- 20Kg

Introduction

The friction coefficient meter is based on the GB 10006 national standard and is professionally suitable for measuring plastic films and sheets, rubber, paper, cardboard, woven bags, fabric styles, metal material composite belts for communication cables and optical cables, conveyor belts, wood, coatings, brake pads, The static friction coefficient and kinetic friction coefficient of wipers, shoe materials, tires and other materials when sliding. By measuring the slippery properties of materials, we can control and adjust material production quality process indicators to meet product usage requirements. In addition, it can also be used to measure the slippery properties of cosmetics, eye drops and other daily chemicals.

Basic application

1. The film is suitable for testing the static friction coefficient and dynamic friction coefficient of plastic films and sheets.

2. Paper is suitable for testing the dynamic and static friction coefficients of paper and cardboard.

3. Textiles, non-woven fabrics, and woven bags are suitable for testing the static friction coefficient and dynamic friction coefficient of textiles, non-woven fabrics, and woven bags.

4. Rubber is suitable for testing the static friction coefficient and kinetic friction coefficient of rubber.

5. Aluminum foil, aluminum foil composite film, and metal products are suitable for testing the static friction coefficient and dynamic friction coefficient of aluminum foil, aluminum foil composite film, and metal products.

6. Printed matter is suitable for testing the static friction coefficient and kinetic friction coefficient of printed matter.

Features

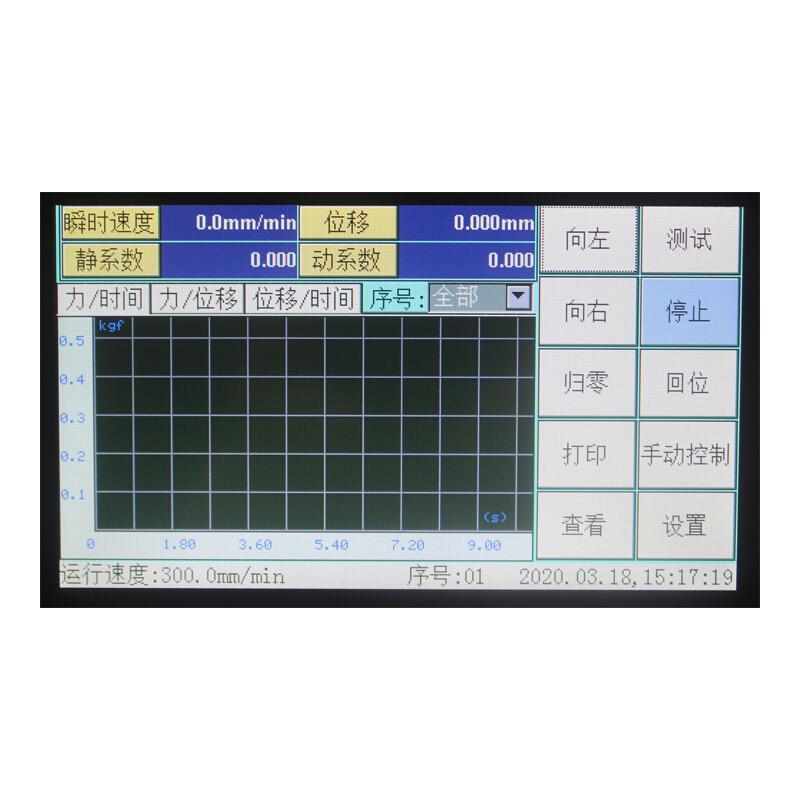

1. The equipment is controlled by a microcomputer, the test process is automated, and it is equipped with a menu-type operation interface, a PVC control panel and an LCD display to facilitate users to conduct test operations and view data.

2. System accessories are all made of components from familiar manufacturers, with stable and reliable performance. High-precision force sensors reach domestic (CN) test accuracy: 0.001N.

3. No mechanical knobs, fully digital system, digital correction and zero adjustment.

4. Specially designed drive system runs smoothly and the test results are more accurate.

5. The system can simultaneously measure the static friction coefficient and kinetic friction coefficient of the sample.

6. Equipped with a micro printer to automatically print test reports for single or group samples.

7. The instrument test bench and test slide have been degaussed and residual magnetism detected, effectively reducing system test errors.

8. Group data, embedded data statistical analysis function.

9. The instrument interface design is simple, the operation is simpler, and it is easy to use.

According to the standard

GB 10006, GB/T 17200, GB/T22895, ISO 8295, ASTM D1894, TAPPI T816.

- 1GB/T 44572-2024《Biaxially oriented polyethylene (BOPE) film》

- 2GB/T 19787-2025《Encasement material, polyolefin thermal cissing film》

- 3GB/T 16311-2024《Specification and test method for road traffic markings》

- 4SY/T 6863-2012《Calibration method of mudcake coefficient device》

- 5JT/T 763-2017《Pendulum friction tester》

- 6GB/T 10006-1988《Plastics--Film and sheeting--Determination of the coefficients of friction》

- 7GB/T 10006-2021《Plastics—Film and sheeting—Determination of the coefficients of friction》

- 8ASTM C1028-2017《Standard Test Method for Determining the Static Coefficient of Friction of Ceramic Tile and Other Like Surfaces by the Horizontal Dynamometer Pull-Meter Method》

NBC-3009

NBC-3009